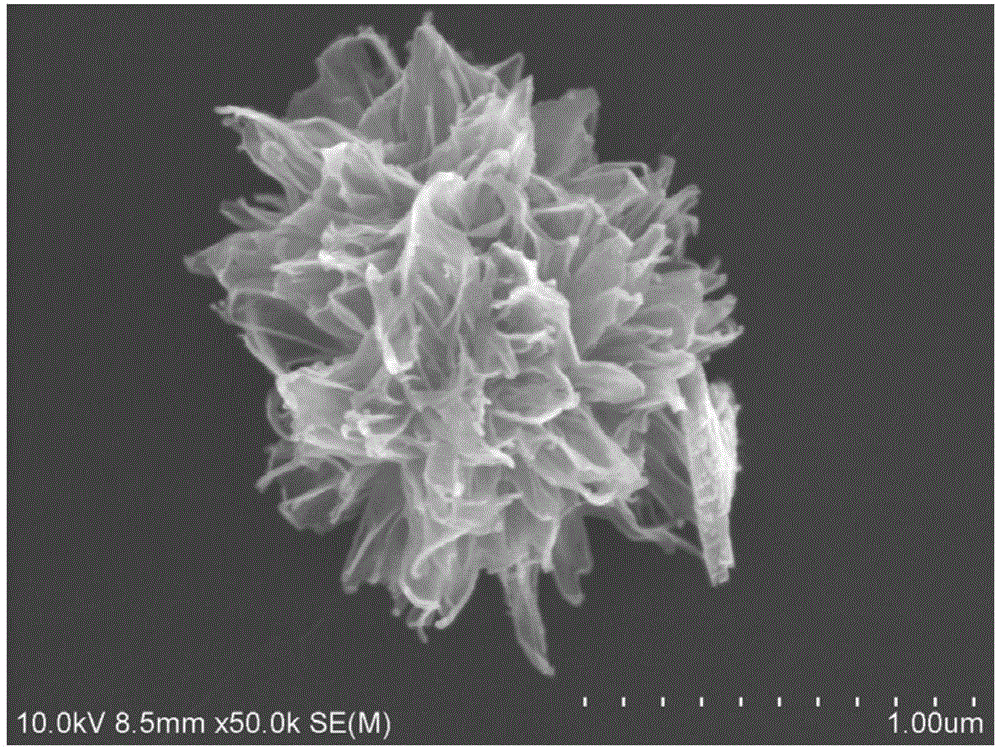

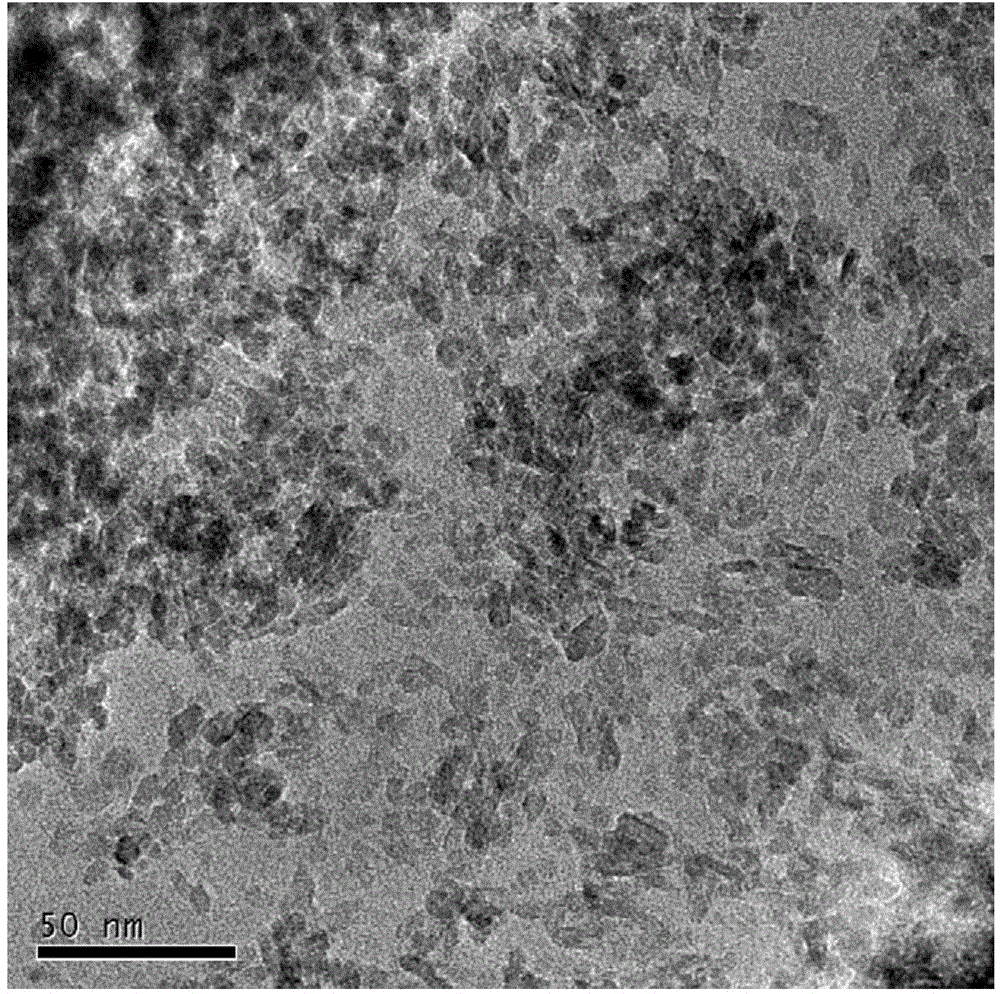

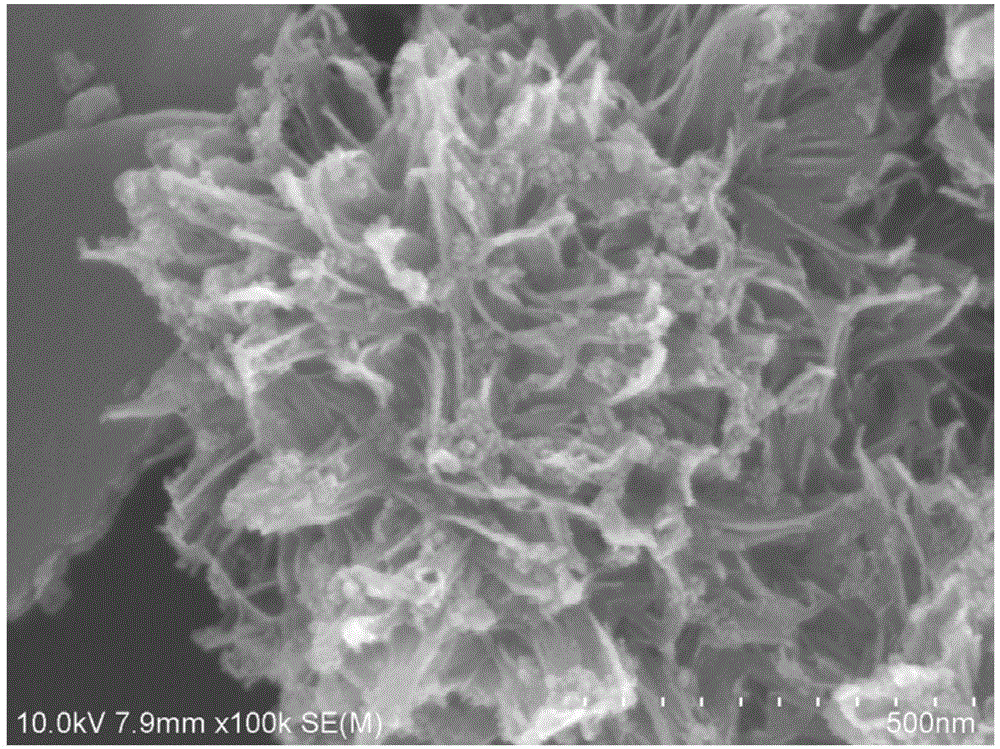

A kind of graded mixed crystal tio2 micro-nano material, preparation method and application thereof

A micro-nano and nano-sheet technology, applied in the field of photocatalysis, can solve problems such as limiting catalytic activity and structural stability, and achieve the effects of excellent catalytic activity, simple process flow, and easy popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Put 0.67 mol / L metal Ti powder into a mixed solution of 9 mol / L hydrogen peroxide and 0.8 mol / L nitric acid (the total volume is kept at 150 mL), condense and reflux in an oil bath at 80°C for 2 hours to obtain orange Yellow solution, hydrothermal reaction with 10mol / L NaOH solution at 150°C for 5 hours, after natural cooling to room temperature, centrifuge the product, wash once with 0.1mol / L nitric acid and wash with water until the pH value is 7 , dried and calcined at 450°C to obtain anatase graded TiO 2 ;

[0064] (2) Add 0.2mol / L tetrabutyl titanate dropwise to a mixed solution of 1.36mol / L concentrated hydrochloric acid and 3mL absolute ethanol, stir evenly in a polytetrafluoroethylene liner, remove 31mL Ionized water was mixed with the above solution, and after stirring for 30 minutes, the liner was sealed and placed in a stainless steel reaction kettle, and the hydrothermal reaction was carried out at 120°C, and the reaction time was 24 hours. After natural...

Embodiment 2

[0073] (1) Put 0.67 mol / L metallic Ti powder into a mixed solution of 9 mol / L hydrogen peroxide and 0.6 mol / L nitric acid (the total volume is kept at 150 mL), condense and reflux in an oil bath at 90°C for 2 hours to obtain orange Yellow solution, hydrothermal reaction with 10mol / L NaOH solution at 150°C for 5 hours, after natural cooling to room temperature, centrifuge the product, wash with 0.05mol / L nitric acid for 5 times, then wash with water until the pH value is 7 , dried and calcined at 350°C to obtain anatase graded TiO 2 ;

[0074] (2) Add 0.3mol / L tetrabutyl titanate dropwise to a mixed solution of 4mol / L concentrated hydrochloric acid and 3mL ethanol, stir well in a polytetrafluoroethylene liner, mix 31mL deionized water with The above solutions were mixed and stirred for 30 minutes, then the inner tank was sealed and placed in a stainless steel reaction kettle, and the hydrothermal reaction was carried out at 120° C., and the reaction time was 24 hours. After n...

Embodiment 3

[0078] (1) Put 0.067 mol / L metallic Ti powder into a mixed solution of 5 mol / L hydrogen peroxide and 0.1 mol / L nitric acid (the total volume is kept at 150 mL), condense and reflux in an oil bath at 80°C for 1 hour to obtain orange Yellow solution, hydrothermal reaction with 5mol / L NaOH solution at 120°C for 1 hour, after natural cooling to room temperature, centrifuge the product, wash twice with 0.5mol / L nitric acid, then wash with water until the pH value is 6.5 , dried and calcined at 450°C to obtain anatase graded TiO 2 ;

[0079] (2) Add 0.02mol / L tetrabutyl titanate dropwise to a mixed solution of 0.1mol / L concentrated hydrochloric acid and 3mL ethanol, stir evenly in a polytetrafluoroethylene liner, add 90mL deionized water Mix with the above solution, stir for 10 minutes, seal the liner and put it into a stainless steel reaction kettle, carry out hydrothermal reaction at 100°C, and the reaction time is 12 hours. After naturally cooling to room temperature, the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com