A kind of processing method of cellulosic ethanol fermentation waste liquid

A technology for cellulosic ethanol and fermentation waste liquid, applied in the field of water treatment, can solve the problems of high investment and operating costs, large area of aerobic process, incomplete degradation of organic matter, etc., to save investment and operating costs, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

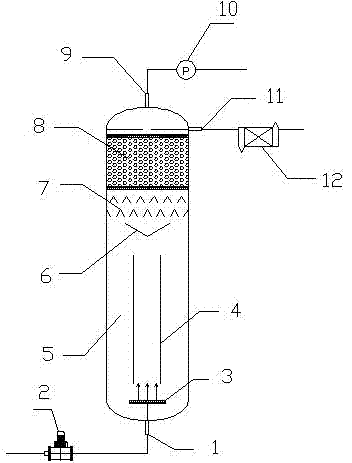

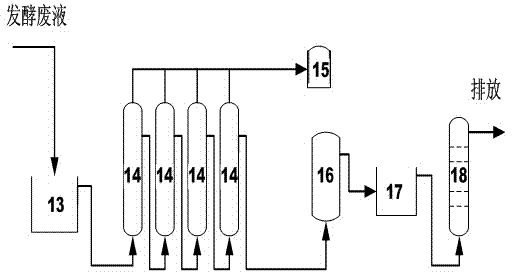

[0026] Adopt the present invention to attach figure 1 processing methods and figure 2 The high-efficiency pressure anaerobic reactor is used to treat the fermentation waste liquid produced by a medium-scale test-scale cellulosic ethanol production device in China. The device uses corn stalks as raw materials, and mainly adopts processes such as steam acid explosion pretreatment, enzymatic hydrolysis, sugar solution fermentation, ethanol concentration and rectification purification to produce cellulose ethanol. The main pollutants in the cellulosic ethanol fermentation waste liquid are COD 129050mg / L, sulfate 9920mg / L, chromaticity 12000 degrees, C:N:P=681:4.8:1, additional nutrients such as N and P must be supplemented, Make C:N:P reach 200:5:1 to meet the needs of biochemical treatment.

[0027] Table 1 Main processing unit composition and processing effect of Embodiment 1

[0028] Handling unit name Processing device scale and main components Main operating...

Embodiment 2

[0031] Using the treatment device in Implementation 1 to treat the same sewage as in Example 1, see Table 2 for the wastewater treatment effects obtained by changing the operating conditions of each treatment unit.

[0032] Main processing unit constitution and processing effect of table 2 embodiment 2

[0033] Handling unit name Processing device scale and main components Main operating conditions and control parameters Treatment effluent or effect Iron filings pretreatment pool The effective volume of the reactor is 5L, and the material is plexiglass, mainly including perforated gas distribution plate, overflow weir, DO online instrument, and the filling ratio of iron filings is 50%. The bottom is continuously fed with water, the flow rate of water is 1L / h, the residence time of wastewater is 5h, and DO is kept at 0.2-0.5mg / L, and the top overflows. The effluent COD is 126000mg / L, the sulfate is 9250mg / L, the color is 12000 degrees, and the total Fe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com