A kind of antirust paint for metal lamp decoration and preparation method thereof

An anti-rust paint and lighting technology, applied in the field of coatings, can solve the problems of no dust-proof effect, easy aging, poor anti-rust effect, etc., and achieve the effects of good protection and decoration, not easy to age, and long anti-rust time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

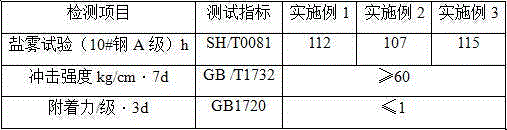

Embodiment 1

[0009] This embodiment provides an anti-rust paint for metal lighting, which contains the following ingredients in parts by mass: 48 parts of white latex, 12 parts of zinc oxide, 15 parts of talc, 8 parts of zinc phosphate, 6 parts of cobalt naphthenate, and mica oxide 4 parts of iron, 4 parts of borate, 1.8 parts of dimethyl silicone oil, 4.5 parts of borax, 1.5 parts of baking glue, 5 parts of organic bentonite, 28 parts of water.

[0010] The preparation steps of an anti-corrosive paint for metal lighting are as follows: first add water to a stirrer, add white latex, zinc oxide, talc, zinc phosphate, cobalt naphthenate, mica iron oxide, Borate, dimethyl silicone oil, borax and baking glue, then stir evenly at a speed of 1200r / min, then add organic bentonite, mix and stir evenly, then grind, grind to a fineness of ≤30μm, and filter to obtain the finished product.

Embodiment 2

[0012] This embodiment provides an anti-rust paint for metal lighting, which contains the following ingredients in parts by mass: 32 parts of white latex, 7 parts of zinc oxide, 6 parts of talc, 3 parts of zinc phosphate, 2 parts of cobalt naphthenate, and mica oxide 1.2 parts of iron, 2 parts of borate, 0.3 parts of dimethyl silicone oil, 1.5 parts of borax, 0.5 parts of baking glue, 2 parts of organic bentonite, 15 parts of water.

[0013] The preparation steps of a kind of anti-rust paint for metal lighting are as follows: first add water into a stirrer, heat up to 60~70℃, add white latex, zinc oxide, talc, zinc phosphate, cobalt naphthenate, mica oxidation while stirring Iron, borate, dimethyl silicone oil, borax and baking glue, then stir evenly at a speed of 1000~1200r / min, then add organic bentonite, mix and stir evenly, then grind, grind to a fineness of ≤30μm, and filter it. Get the finished product.

Embodiment 3

[0015] This embodiment provides an anti-rust paint for metal lighting, which contains the following components in parts by mass: 40 parts of white latex, 10 parts of zinc oxide, 10 parts of talc, 5.5 parts of zinc phosphate, 4 parts of cobalt naphthenate, and mica oxide 2.6 parts of iron, 3 parts of borate, 1.1 parts of dimethyl silicone oil, 3 parts of borax, 1 part of baking glue, 3.5 parts of organic bentonite, 26 parts of water.

[0016] The preparation steps of a kind of anti-rust paint for metal lighting are as follows: first add water into a stirrer, heat up to 60~70℃, add white latex, zinc oxide, talc, zinc phosphate, cobalt naphthenate, mica oxidation while stirring Iron, borate, dimethyl silicone oil, borax and baking glue, then stir evenly at a speed of 1000~1200r / min, then add organic bentonite, mix and stir evenly, then grind, grind to a fineness of ≤30μm, and filter it. Get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com