High-temperature-resistant non-expansion type flameproof and anticorrosive paint and preparation method thereof

A non-intumescent, anti-corrosion coating technology, used in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve problems such as only reaching about 700 ° C, peeling or coking, loss of anti-corrosion, etc., to achieve protection from damage, strong anti-corrosion Corrosion performance, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

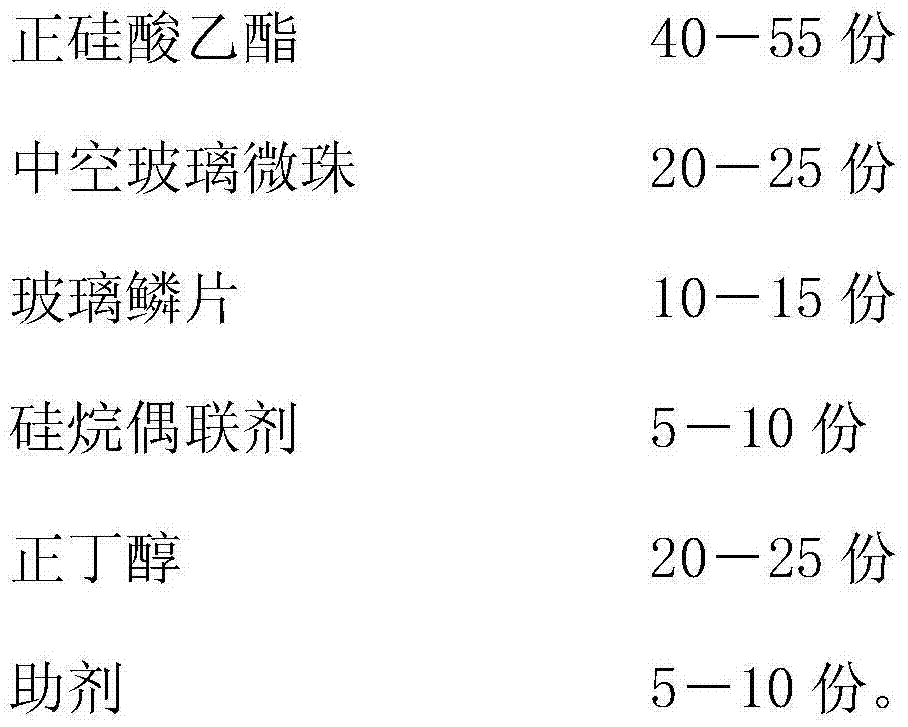

Embodiment 1

[0016] A preparation method of high temperature resistant non-expandable fireproof and anticorrosion coating, the preparation method is as follows: 40 parts of tetraethyl orthosilicate-32, 20 parts of hollow glass microspheres, 10 parts of glass flakes, 5 parts of silane coupling Add agent KH-55O, 5 parts of dispersant HX-4030 and 20 parts of n-butanol directly into the stirring tank for mixing and stirring, the stirring speed is 800r / min, and the stirring time is 30min.

Embodiment 2

[0018] A preparation method of high temperature resistant non-expandable fireproof and anticorrosion coating, the preparation method is as follows: 50 parts of tetraethyl orthosilicate-32, 23 parts of hollow glass microspheres, 12 parts of glass flakes, and 8 parts of silane coupling Add agent KH-55O, 8 parts of dispersant HX-4030 and 22 parts of n-butanol directly into the stirring tank for mixing and stirring, the stirring speed is 900r / min, and the stirring time is 40min.

Embodiment 3

[0020] A preparation method of high temperature resistant non-expandable fireproof and anticorrosion coating, the preparation method is as follows: 55 parts of tetraethyl orthosilicate-32, 25 parts of hollow glass microspheres, 15 parts of glass flakes, 10 parts of silane coupling Add agent KH-55O, 10 parts of dispersant HX-4030 and 25 parts of n-butanol directly into the stirring tank for mixing and stirring, the stirring speed is 1000r / min, and the stirring time is 45min.

[0021] The high temperature resistant non-intumescent fireproof and anticorrosion coating of the present invention is carried out each performance test, and data is as follows table 1:

[0022] Table 1 High temperature resistant non-expandable fireproof and anticorrosion coating performance testing data of the present invention

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com