Granular material for shale gas development and preparation method thereof

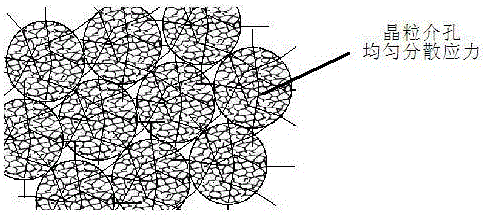

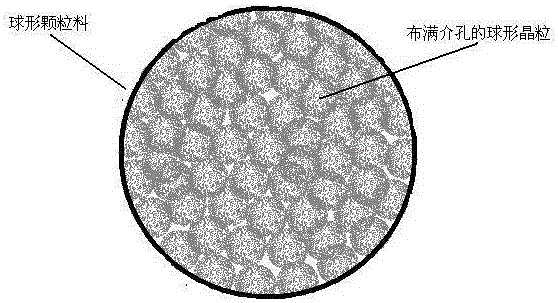

A granular material and shale gas technology, which is applied in the fields of mining fluids, chemical instruments and methods, earthwork drilling and production, etc., can solve the problems that it is difficult to adapt to the high closure pressure of shale gas, the anti-fragmentation ability has not been significantly improved, and the stress cannot be transferred. , to achieve the effect of expanding selection, high compressive strength, and reducing content requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Pre-firing 5 parts by weight of porous nano-diatomite at a low temperature of 600°C for 60 minutes to obtain porous nano-porcelain powder, which has through-hole mesopores and has certain strength and toughness;

[0046] 2) Grind 90 parts by weight of mineral composite powder and 1 part by weight of crystal phase inducer in a jet mill until they are completely sieved through a 1250-mesh sieve, and then mix with the porous nano-porcelain powder obtained in step 1), 1 part by weight Parts of carboxymethyl starch and appropriate amount of water are uniformly mixed in a high-speed mixer, wherein the composite mineral powder is composed according to the following parts by weight: 80 parts of brucite, 10 parts of quartz stone, 8 parts of basalt, and 3 parts of pyrophyllite , 1 part of wollastonite, 2 parts of alunite;

[0047] 3) Send the material obtained in step 2) into a ball mill, add 1% sodium polystyrene sulfonate as the grinding material, and grind for 10-20 minutes...

Embodiment 2

[0053] 1) 4 parts by weight of porous nano-SiO 2 Pre-fired at a low temperature of 500°C for 45 minutes to obtain porous nano-porcelain powder, which has through-hole mesopores and has certain strength and toughness;

[0054] 2) Grind 95 parts by weight of mineral composite powder and 1.5 parts by weight of crystal phase inducer in a jet mill until they are completely sieved through a 1250-mesh sieve, and then mix with the porous nano-porcelain powder obtained in step 1), 1 wt. Parts of polyvinyl acetate and appropriate amount of water are uniformly mixed in a high-speed mixer, wherein the composite mineral powder is composed according to the following parts by weight: 75 parts of brucite, 15 parts of quartz stone, 6 parts of basalt, and 5 parts of pyrophyllite , 2 parts of wollastonite, 1 part of alunite;

[0055] 3) Send the material obtained in step 2) into a ball mill, add 1% polyvinyl sodium sulfate as the grinding material, and grind for 10-20 minutes to obtain agglomer...

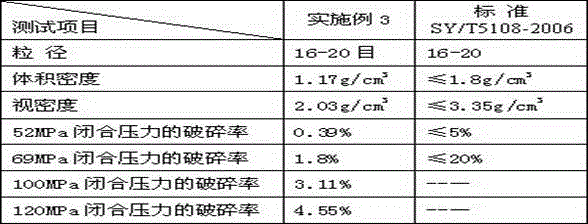

Embodiment 3

[0061] 1) 5 parts by weight of porous nano-SiO 2 Pre-fired at a low temperature of 500°C for 45 minutes to obtain porous nano-porcelain powder, which has through-hole mesopores and has certain strength and toughness;

[0062] 2) Grind 90 parts by weight of mineral composite powder and 1.5 parts by weight of crystal phase inducer in a jet mill until they are completely sieved through a 1250-mesh sieve, and then mix with the porous nano-porcelain powder obtained in step 1), 0.5 parts by weight Parts of sodium aluminate and an appropriate amount of water are uniformly mixed in a high-speed mixer, wherein the composite mineral powder is composed according to the following parts by weight: 80 parts of brucite, 10 parts of quartz stone, 5 parts of basalt, 5 parts of pyrophyllite, 2 parts of wollastonite, 1 part of alum stone;

[0063] 3) Put the material obtained in step 2) into a ball mill, add 1% sodium polyacrylate grinding aid to the grinding material, grind for 10-20 minutes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com