Pretensioned Prestressed Concrete Hollow Corner Pile

A concrete pile and concrete technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of uneven stress, poor compressive and bending performance of pipe piles, unreasonable structure and reinforcement, etc. Excellent mechanical properties, reasonable reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

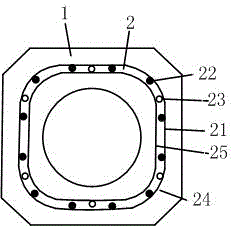

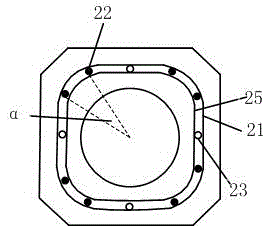

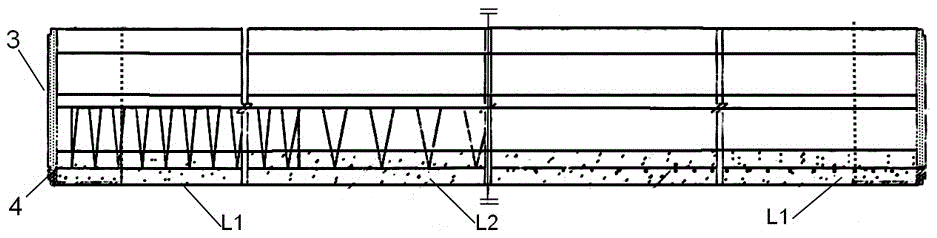

[0017] Such as figure 1 As shown, the regular quadrilateral chamfered pile of the 400×400mm model of the present invention includes a concrete pile body 1 and a reinforcement cage 2 positioned inside the concrete pile body 1, and the reinforcement cage 2 mainly includes spiral stirrups 21, prestressed tendons 22, An outstanding feature of the anchor bars 23 and erecting stirrups 25 is that the cross-section of the reinforcement cage 2 is a polygon with cut corners 24, and the cut corners 24 are arc-shaped. The advantage of cutting corners in an arc shape is that the thickness of the concrete on both sides of the prestressed tendons on the cutting corners is basically the same, and the stress at the connection between the long side and the short side can also be reduced. Specifically, the erecting stirrups 21 are polygonal with cut corners 24, and the cut corners 24 are arc-shaped spiral stirrups 21 located outside the erecting stirrups 21, thereby forming the basic structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com