Combined double-row-pile combined vertical prestress anchor rod supporting system and construction method thereof

A technology of vertical prestressing and bolt support, which is applied in excavation, foundation structure engineering, construction, etc., to achieve the effects of saving construction period, high rigidity against lateral displacement, and control of lateral displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

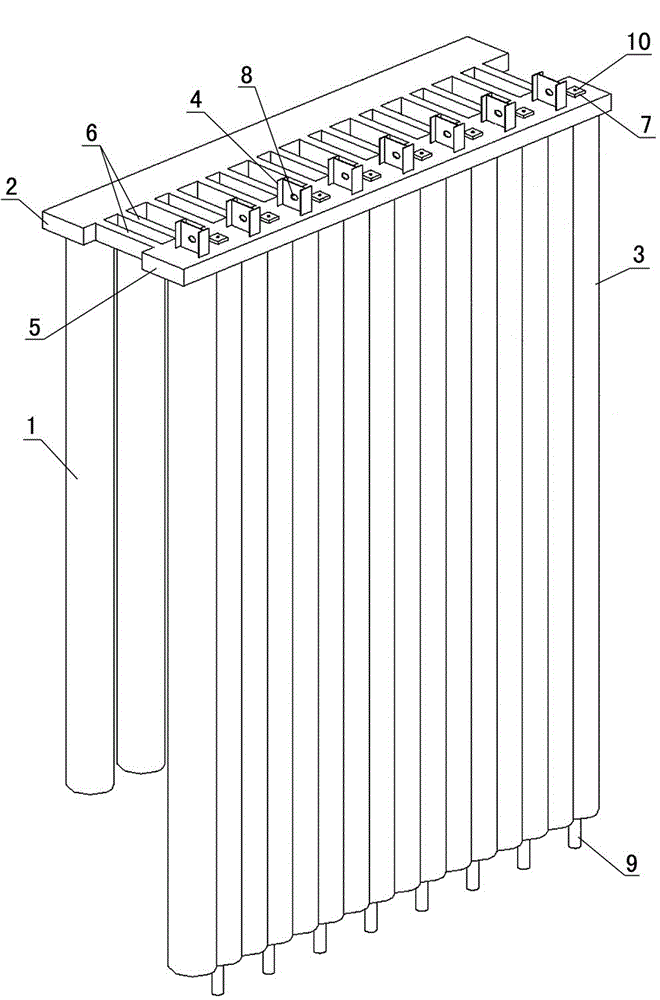

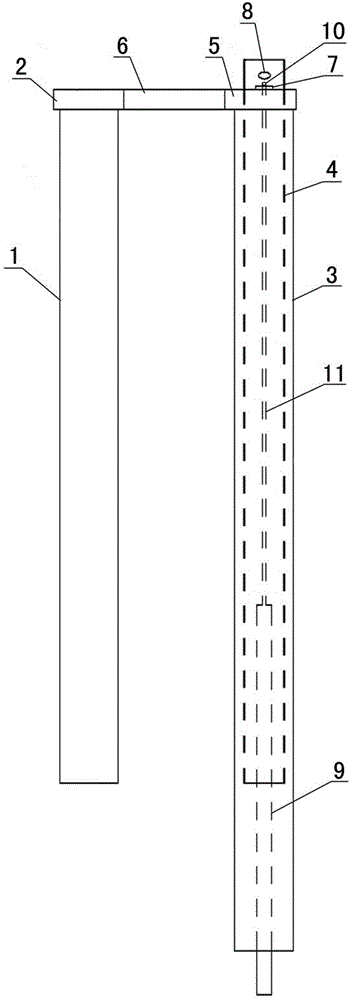

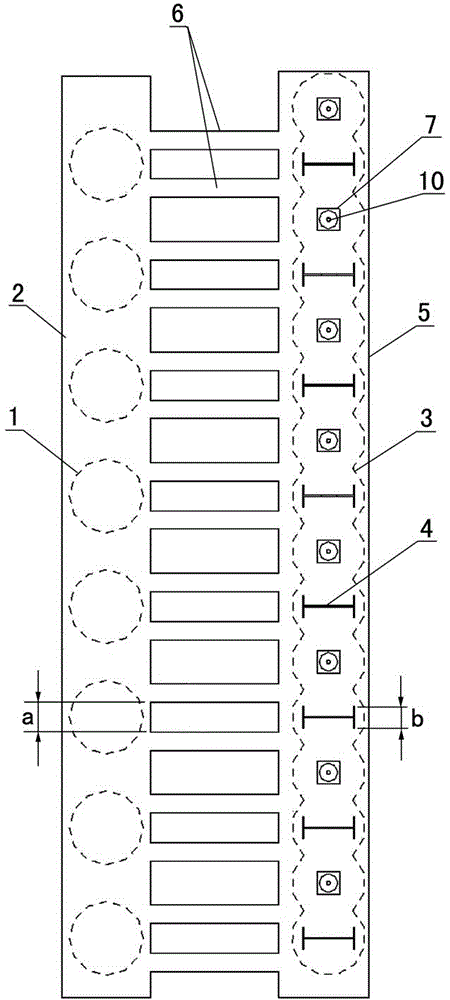

[0031] Examples see Figure 1-3 As shown, this combined double-row pile joint vertical prestressed bolt support system includes a front row of piles 1, a front row of pile crown beams 2, a rear row of piles 3, a rear row of pile crown beams 5 and Connection beam 6.

[0032] The front row of piles 1 is a row of reinforced concrete piles arranged at parallel intervals, the rear row of piles 3 is a shaped steel cement-soil mixing pile wall, and the connecting beam 6 is a double-leg connecting beam (to facilitate the formation of the shaped steel cement-soil mixing pile wall). section steel in the wall);

[0033] The inserted section steel 4 in the section steel cement-soil mixing pile wall is H-section steel, and the upper end of the H-section steel is exposed above the top crown beam 5 of the rear row of piles. In this embodiment, the upper end of the H-section steel is also provided with There are lifting holes 8 for the section steel, and the exposed length of the H section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com