A combined corrugated frame shear assembly energy dissipation structure system

A technology of combining grooves and grooves, which is applied in the direction of building components, building structures, earthquake resistance, etc., can solve the problem of strong energy consumption capacity of the force transmission path, achieve superior energy consumption capacity and ductility, ensure construction quality, and good ductility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

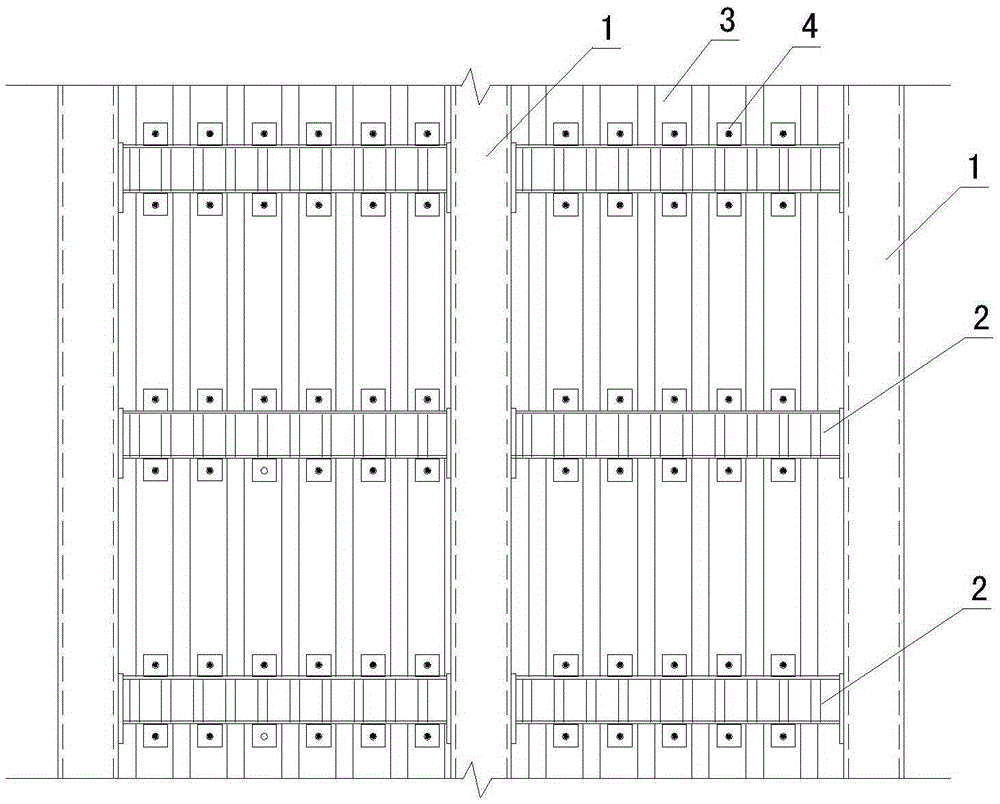

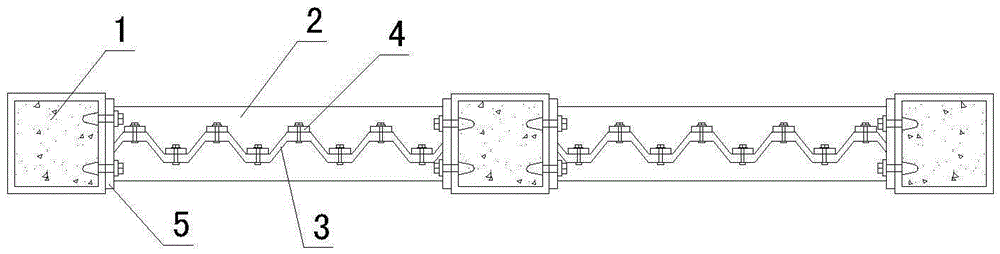

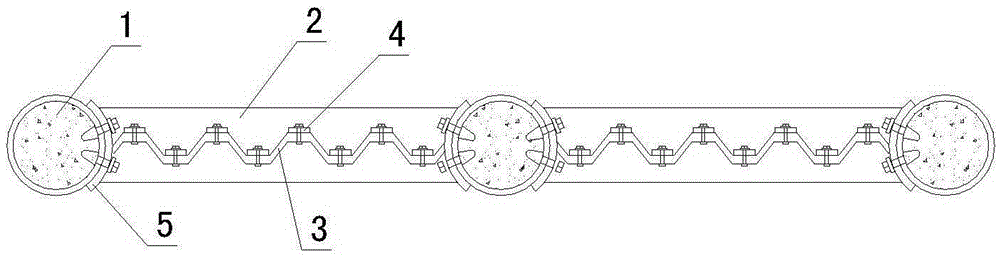

[0025] see figure 1 , the structural form of the combined corrugated frame shear assembly energy-dissipating structural system in this embodiment is: the system adopts steel tube concrete column 1, corrugated web beam 2 and corrugated steel plate shear wall 3; The bolted connection between the corrugated web beam 2 and the corrugated steel plate shear wall 3 is implemented; the cross section of the corrugated web beam 2 is H-shaped, and the flange plate of the The plate is a corrugated steel plate, and the corrugated web beam changes its web form on the basis of ordinary steel beams, which improves its shear bearing capacity, delays the appearance of plastic hinges at nodes, and effectively reduces the section height; The corrugated steel plate shear wall 3 is a corrugated steel plate. The corrugated steel plate buckles first under the action of an earthquake. Benefiting from the corrugated section, it has a strong energy dissipation capacity during buckling and still has a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com