Steel ring mounting machine for tunnel construction

A steel ring installation machine and tunnel construction technology, applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve the problem of difficult precise positioning and installation of large-weight steel plate components, difficult quality and safety of tunnel segment reinforcement, and low installation quality, etc. problems, to achieve the effect of improving kinematics and dynamics characteristics, increasing flexibility and obstacle avoidance ability, and increasing swing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

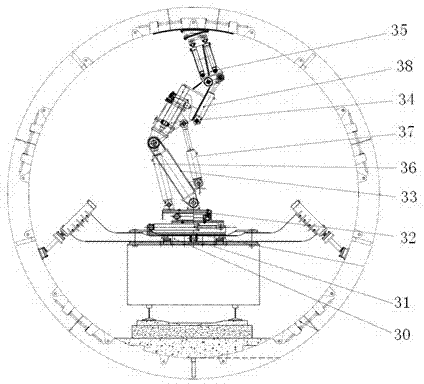

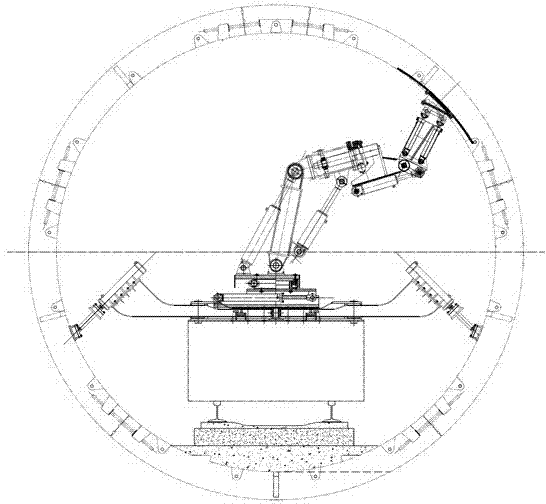

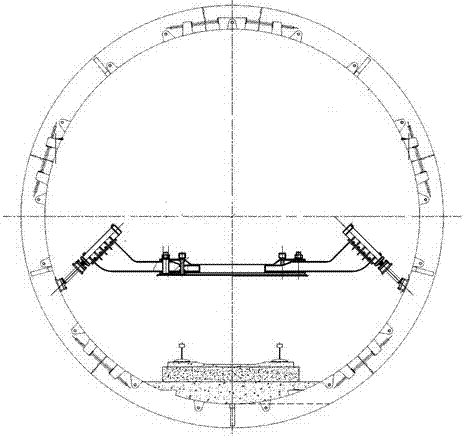

[0029] A steel ring installation machine of the present invention, which is used in operations such as grabbing, lifting and adjusting the attitude of the steel ring during tunnel construction, will be further described in detail below. In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the drawings are all in simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0030] A steel ring installation machine used for grabbing, lifting and adjusting the posture of steel rings during tunnel construction. Please refer to the structure figure 1 . The steel ring installation machine includes a chassis supporting mechanism 30 , a chassis moving mechanism 31 , a chassis turning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com