Inline clutch having middle contact pin

A dual-clutch and middleware technology, applied in the direction of clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve problems such as high moment of inertia, single clutch crosstalk, etc., and achieve high rigidity, good readiness, and simplified assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

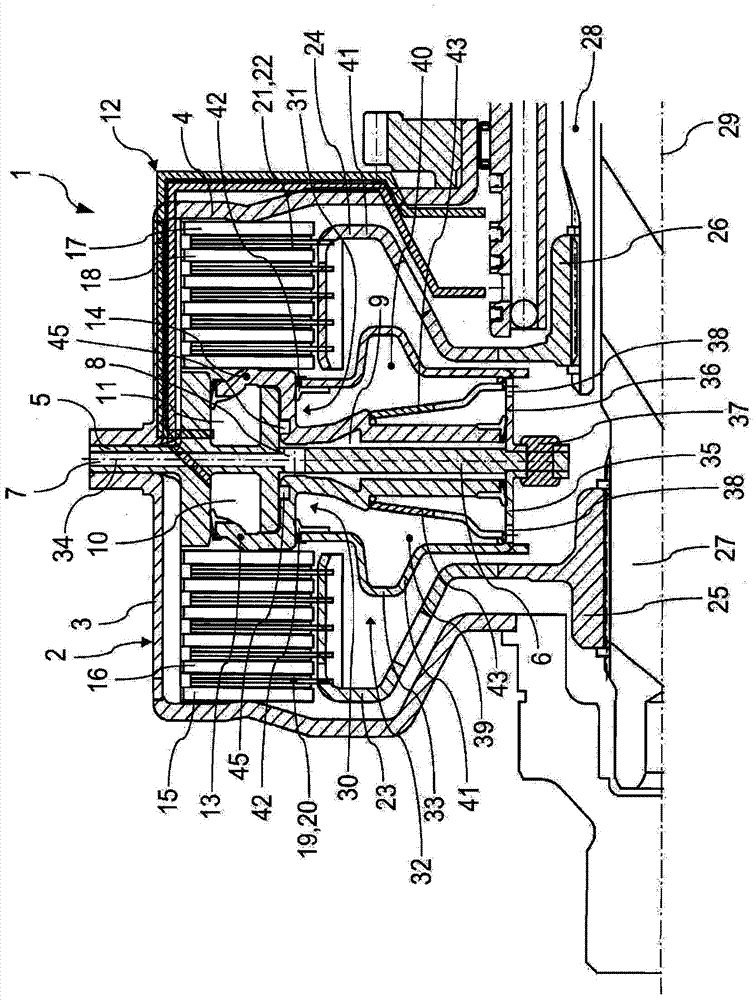

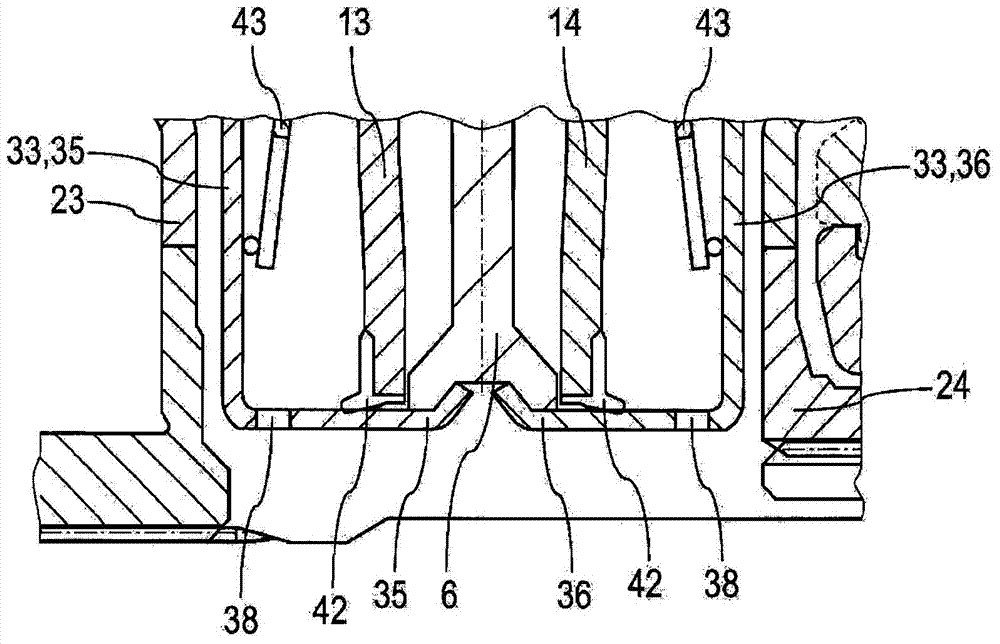

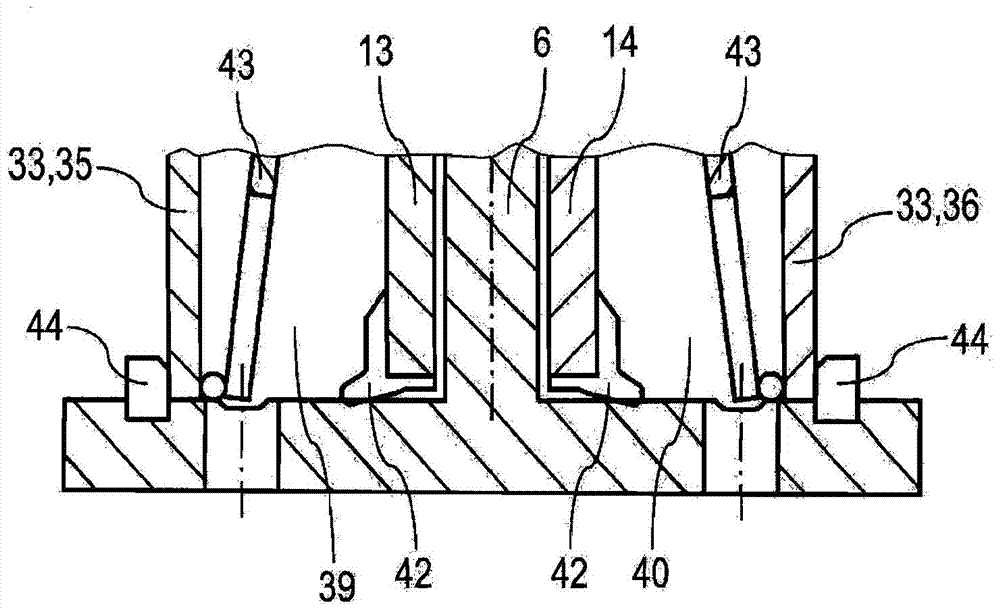

[0060] exist figure 1 A first embodiment of the dual clutch 1 according to the invention is shown in . The dual clutch 1 is a wet-running dual clutch and has an outer disc carrier 2 .

[0061] The outer sheet support 2 is divided into a first outer sheet support installation section 3 and a second outer sheet support installation section 4 . A first friction clutch K1 is located inside the first outer plate carrier mounting section 3 , while a second friction clutch K2 is located radially inside the second outer plate carrier mounting section.

[0062] Between the two outer plate support mounting sections 3 and 4 there is an intermediate part 5 which extends radially inwards and merges into an extension web 6 . The outer disk carrier 2 is riveted radially on the outside to the middle part 5 , so that the two outer disk carrier mounting sections 3 and 4 and the middle part 5 are connected to one another in a rotationally fixed manner.

[0063] A central vent hole 7 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com