Flour mill roller transmission mechanism and flour mill

A technology of transmission mechanism and pulverizer, which is applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of small transmission force, difficult assembly, and difficult installation of toothed wedge belts, so as to prolong the service life, Avoid excessive stretching and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

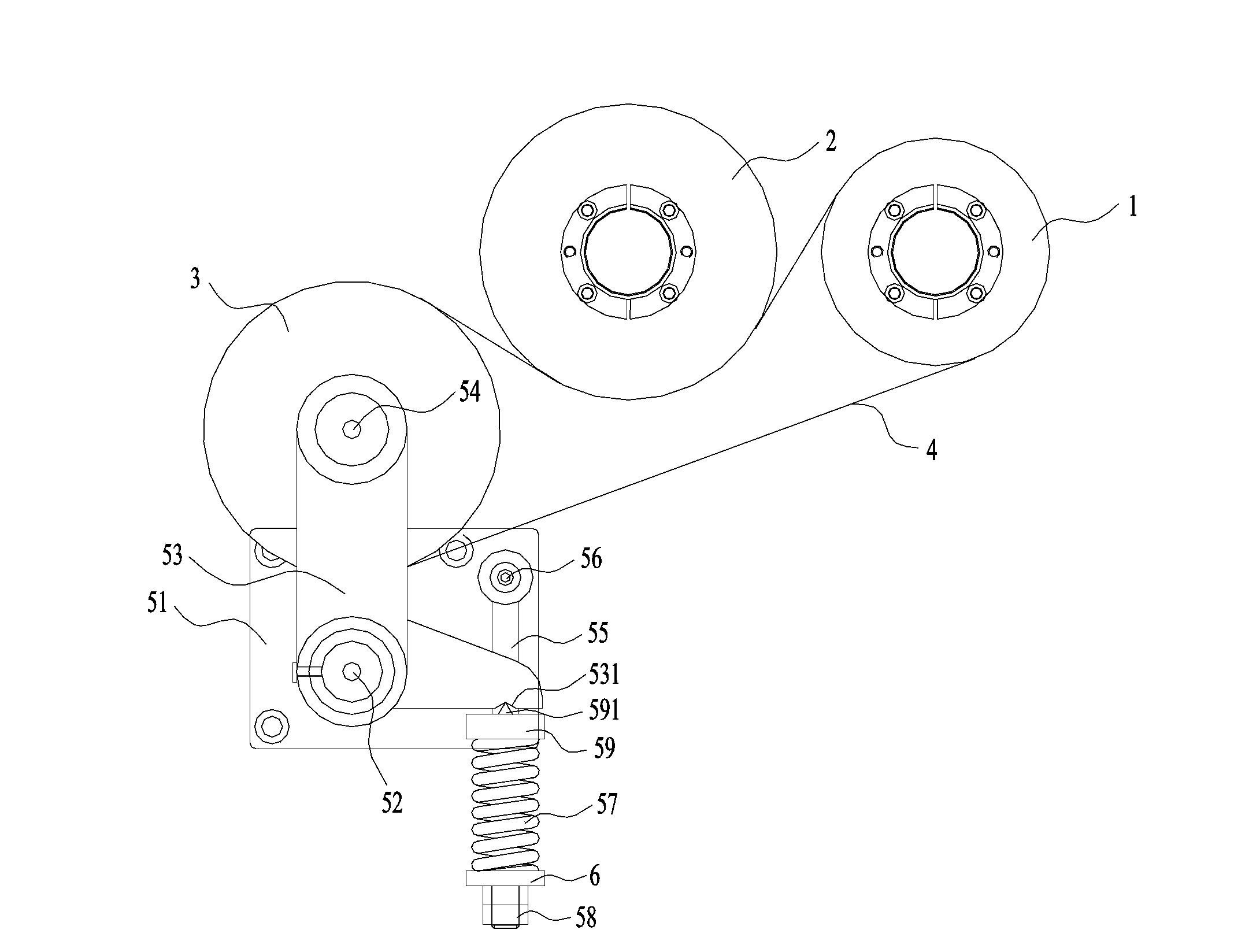

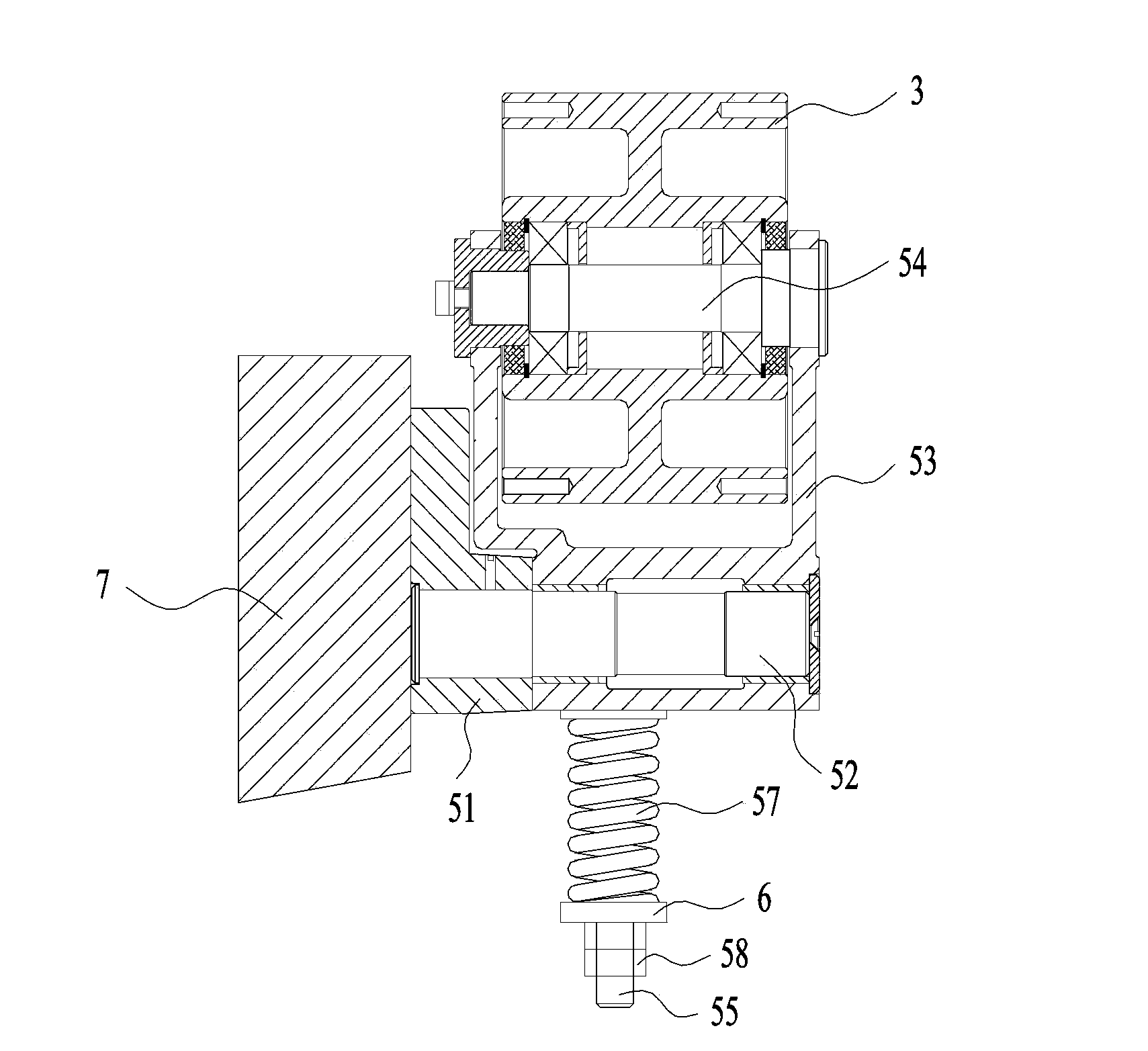

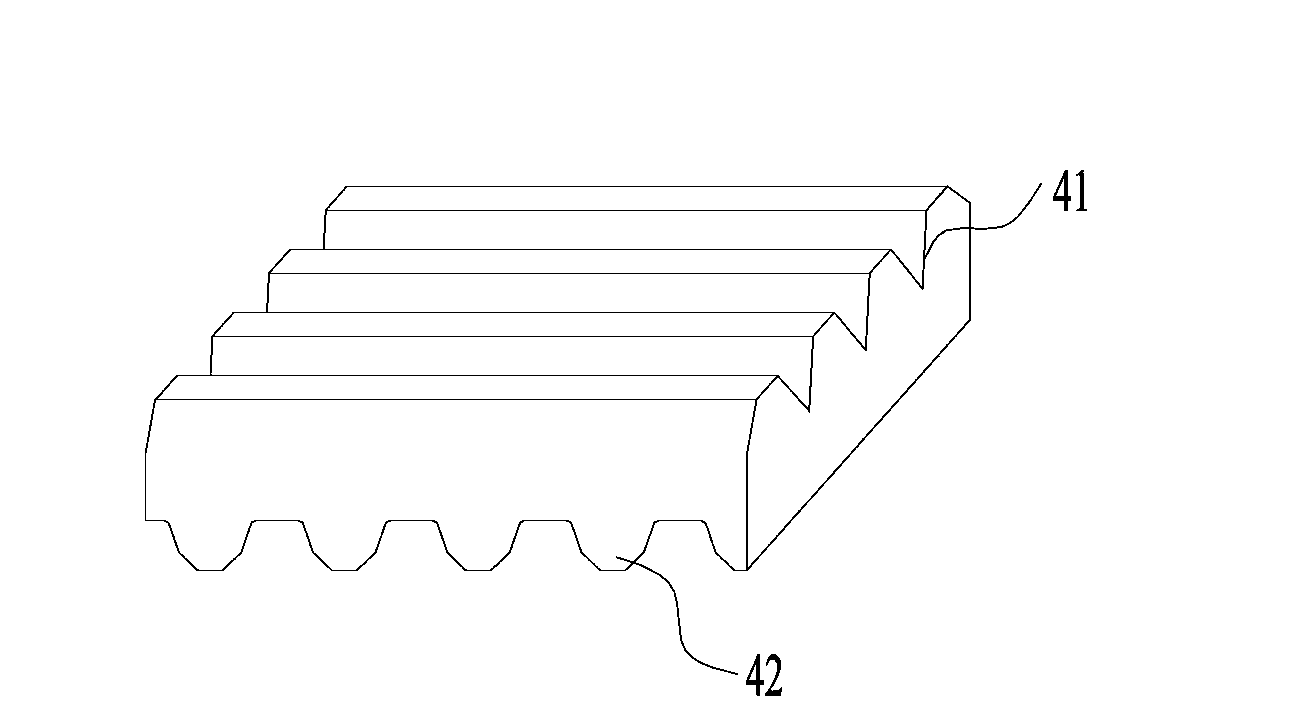

[0043] The mill roller transmission mechanism proposed by the present invention, such as figure 1 , figure 2 As shown, it includes frame 7, fast roller 1, slow roller 2 and toothed wedge belt 4. The outer peripheral surface of the wheel 1 is engaged, the outer tooth surface of the toothed wedge belt 4 is engaged with the outer peripheral surface of the slow roller 2, and the mill roller transmission mechanism also includes:

[0044] Tension seat 51, the tension seat 51 is fixed on the frame 7;

[0045] A support shaft 52, one end of the support shaft 52 is pivotally connected to the tension seat 51;

[0046] Swing frame 53, one side of this swing frame 53 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com