Variable displacement rotor oil pump

A rotor oil pump, variable technology, applied in lubricating pumps, mechanical equipment, engine components, etc., can solve the problems of high operating noise and low oil pump efficiency, and achieve the effects of eliminating noise, simple overall structure, and eliminating transmission faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

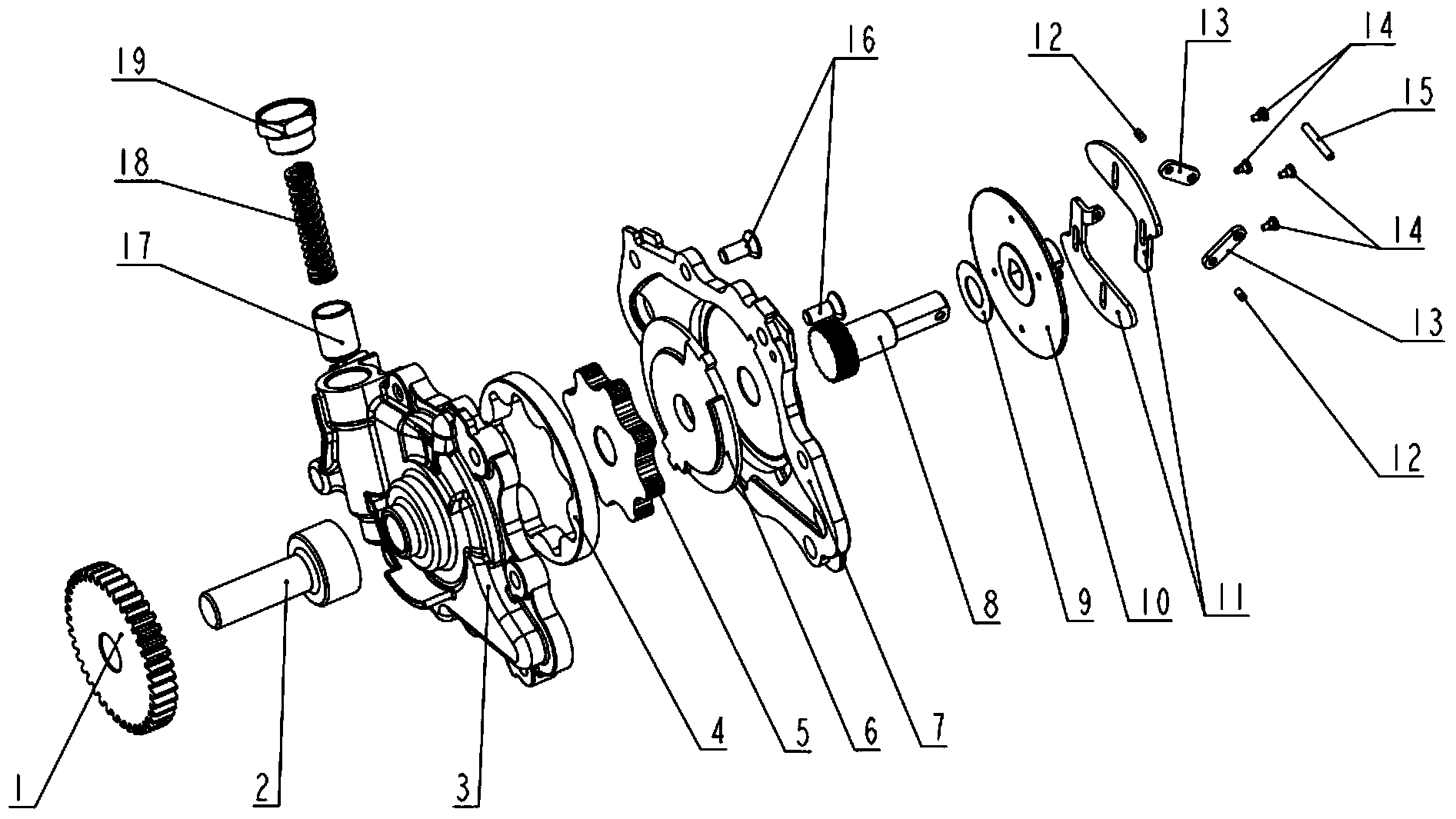

[0053] figure 1 It is an explosion diagram of a variable displacement rotor oil pump according to an embodiment of the present invention. Such as figure 1 As shown, the variable displacement rotor oil pump includes a pump casing 3 and a pump cover 7 facing the pump casing 3 , and bolts 16 are used to fixedly connect the pump casing 3 and the pump cover 7 . In an assembled state, the pump casing 3 and the pump cover 7 will define a receiving chamber between them for receiving the outer rotor 4 , the inner rotor 5 and the push plate 6 .

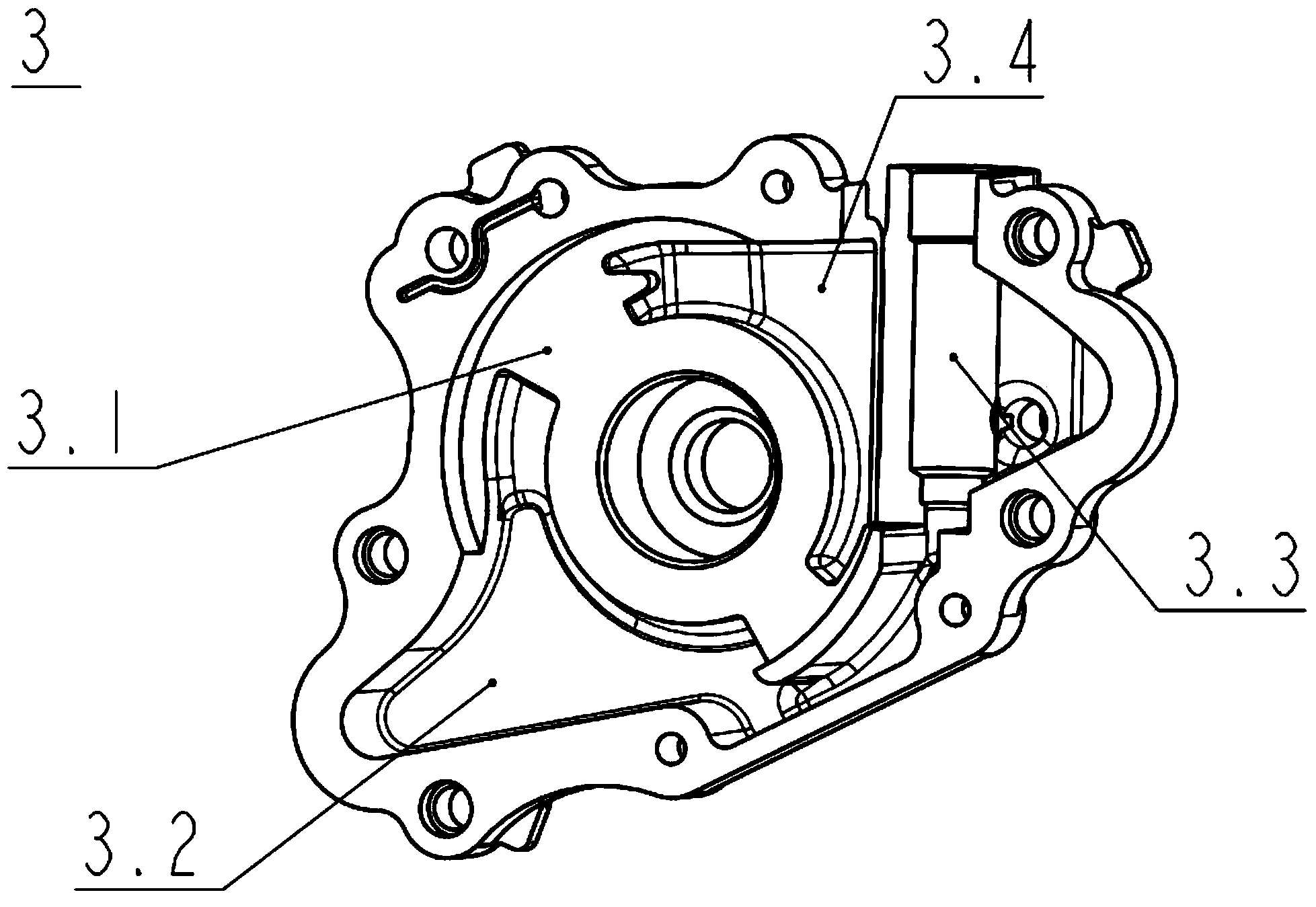

[0054] refer to image 3 , The pump casing 3 has a pump casing low-pressure oil zone 3.4 and a pump casing high-pressure oil zone 3.2 spaced apart. refer to Figure 5 , similarly, the pump cover 7 also has a pump cover low-pressure oil zone 7.1 and a pump cover high-pressure oil zone 7.5 spaced apart. In this way, when as Figure 12 and Figure 15 As shown, after the pump casing 3 and the pump cover 7 are assembled facing each other, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com