Ship and offshore oil platform power cable

A technology for power cables and offshore oil, applied in the field of power cables, can solve the problems of easy breakdown of the insulating layer, short life, poor reliability, etc., and achieve the effects of reducing partial discharge, improving service life, and reducing surface gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

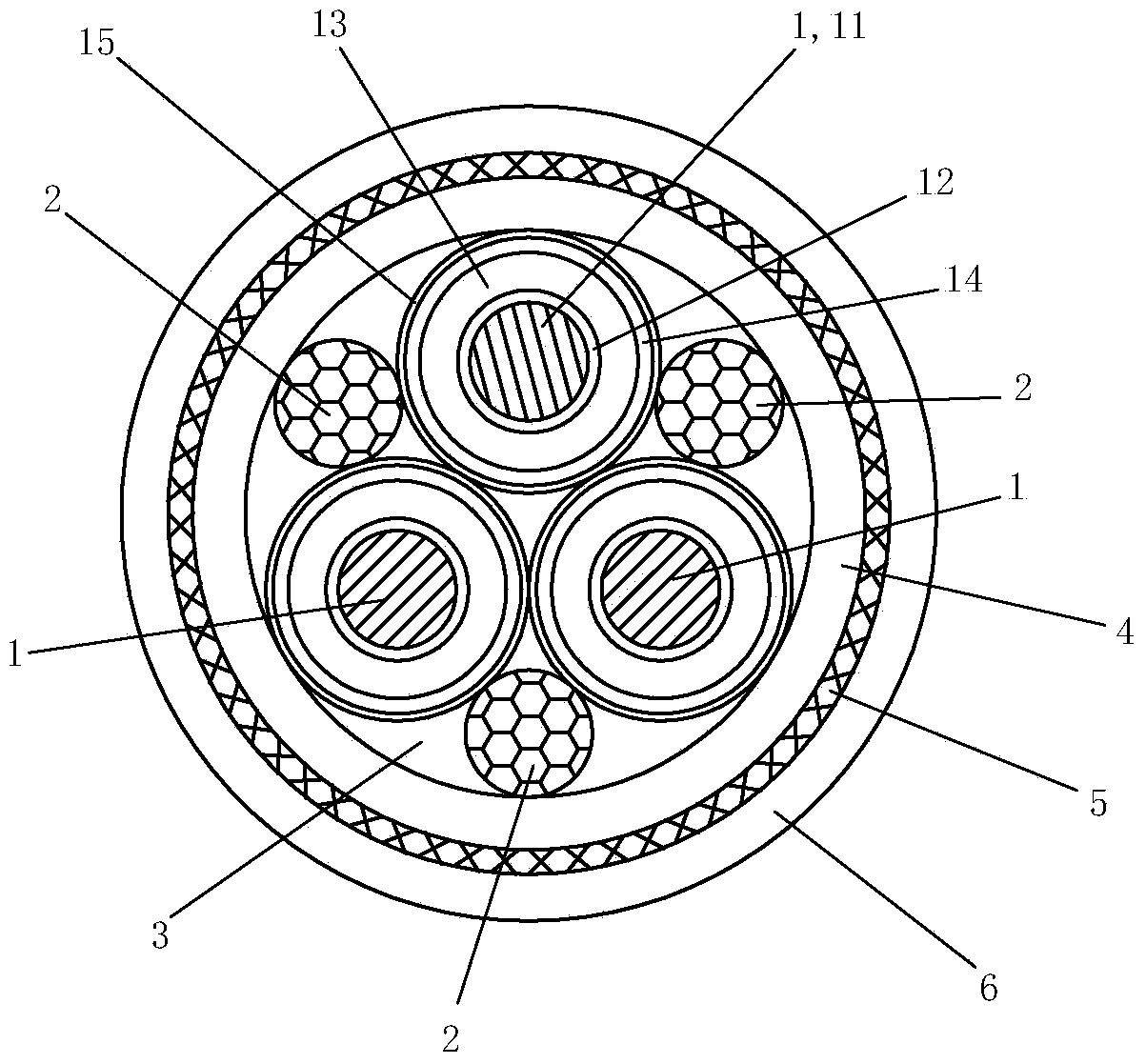

[0030] See figure 1 , The power cable for ships and offshore oil platforms of this embodiment includes a main core 1, a filling strip 2, a wrapping tape 3, an inner sheath 4, an armor layer 5 and an outer sheath 6.

[0031] There are three main cores 1, and the three main cores 1 have the same structure. The three main cores 1 are arranged at equal intervals along the circumference of the power cable. The three main cores 1 are provided with a conductor 11 , a conductor shielding layer 12 , an insulating layer 13 , an insulating non-metallic shielding layer 14 and an insulating metal shielding layer 15 sequentially from inside to outside along their respective radial directions.

[0032] The conductor 11 is formed by twisting and pressing 6 or 12 or 15 or 18 or 30 copper wires or metal-plated copper wires with the same diameter and a nominal cross-section of 50 to 185 square millimeters. This embodiment adopts 12 Tinned copper wire with a nominal cross-section of 70 square m...

Embodiment 2)

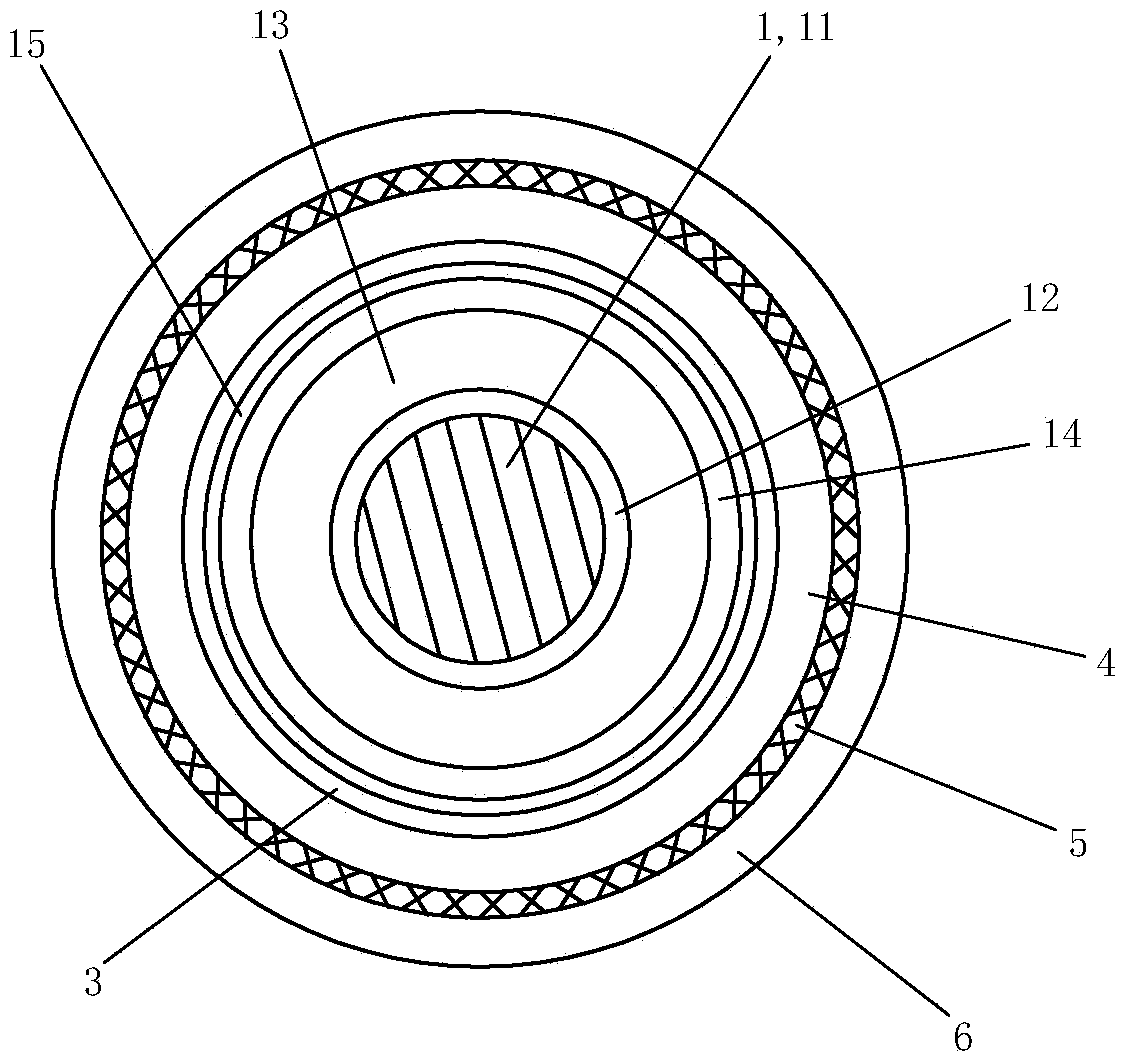

[0045] The remaining parts of the power cable for ships and offshore oil platforms in this embodiment are the same as those in Embodiment 1, except that there is one main core and the filler strip 2 is not included. The wrapping tape 3 is directly wrapped around the outside of the main core 1 . The conductor 11 is twisted by 6 or 12 or 15 or 18 or 30 or 34 or 53 copper wires or metal-plated copper wires with the same diameter and a nominal cross-section of 50 to 400 square millimeters. The embodiment is formed by twisting and pressing 12 tinned copper wires with a nominal cross section of 70 square millimeters. The insulating metal shielding layer 15 is wrapped outside the insulating non-metallic shielding layer 14 with a bare copper tape, the thickness of the bare copper tape is 0.12 mm, and the overlapping rate is 10% to 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com