Capacitor core packet wrapped by puller adhesive tape

A technology of wrapping capacitors and Rama tape, which is applied in the direction of fixed capacitor casing/packaging, fixed capacitor parts, etc., can solve the problems of high defective rate, complicated process, high cost, etc., and achieve small investment, convenient operation, and external beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

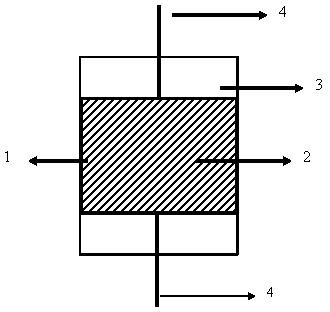

[0015] Refer to the attached figure, in which Rama tape 1, core wrap 2, epoxy layer 3, CP line 4

[0016] A capacitor core package wrapped with pull code tape, the capacitor core package is wrapped with Rama tape outside the core package of welded CP wires, and the width of the Rama tape should be 1cm longer than the core package, so that after wrapping A 0.5cm edge is formed around the gold-sprayed layers on both sides, and the protruding part is sealed with epoxy resin after being wrapped with the code tape, and the CP line of the capacitor lead-out end passes through the epoxy resin sealing layer of the capacitor, and the capacitor The core package should be flattened or sealed with corresponding plastic beads at both ends to seal the hollow caused by the winding mandrel. Insert one end of the above-mentioned core package CP line into the foam plastic board. The core package should be vertical. Pouring epoxy seals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com