A straw-fiber-reinforced spray-on phosphogypsum-based fireproof mortar and its preparation method and application

A straw fiber and gypsum-based technology, which is applied in the field of building materials, can solve the problems of poor fire performance and achieve the effects of ensuring compression resistance, high structural strength and bonding strength, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

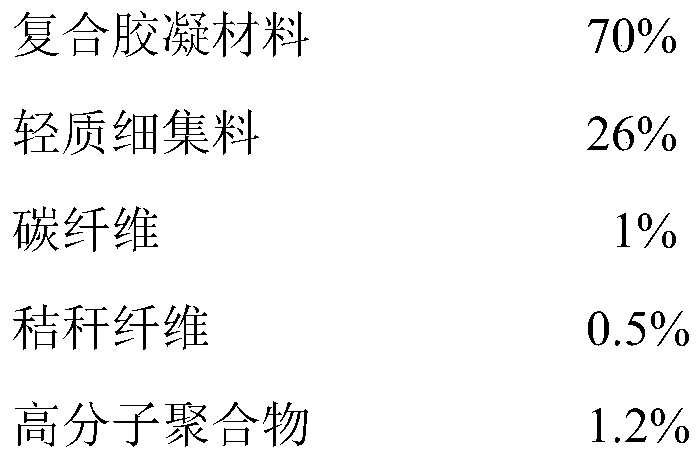

[0043] The straw-fiber-reinforced spray-type phosphogypsum-based fireproof mortar of this embodiment is prepared from the following raw materials according to weight percentage:

[0044]

[0045]

[0046] Among them, the mass ratio of modified phosphogypsum, modified refractory cement and kyanite mineral powder in the composite cementitious material is 6:4:5, and the modified phosphogypsum is a 3% mass fraction of 30℃ oxalic acid aqueous solution to dissolve phosphorus Gypsum is agitated and placed in an ultrasonic device for 25 minutes, then filtered, washed and dried at 30°C; the modified refractory cement is made by mixing nano-silicon carbide and refractory cement for agitation and ultrasonic dispersion The refractory cement is low-calcium aluminate refractory cement or calcium-magnesium aluminate cement, and the mass ratio of nanometer silicon carbide and refractory cement is 1:17; the kyanite in the kyanite mineral powder The quality ratio is 40%.

[0047] In this embodiment...

Embodiment 2

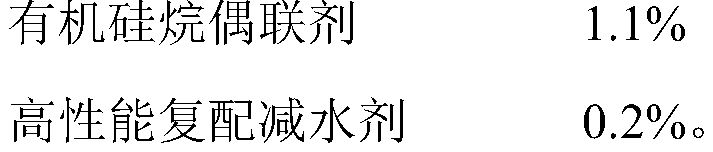

[0055] The straw-fiber-reinforced spray-type phosphogypsum-based fireproof mortar of this embodiment is prepared from the following raw materials according to weight percentage:

[0056]

[0057] Among them, the mass ratio of modified phosphogypsum, modified refractory cement and kyanite mineral powder in the composite cementing material is 10:4:7, and the modified phosphogypsum is a 4% mass fraction of oxalic acid aqueous solution at 35°C to dissolve phosphorus Gypsum, after being stirred, placed in an ultrasonic device for 28 minutes, then filtered, washed, and dried at 32°C; the modified refractory cement is made by mixing nano-silicon carbide and refractory cement with ultrasonic dispersion Processed, wherein the refractory cement is low calcium aluminate refractory cement or calcium magnesium aluminate cement, and the mass ratio of nano-silicon carbide and refractory cement is 1:20; the kyanite in the kyanite mineral powder The quality ratio is 55%.

[0058] In this embodimen...

Embodiment 3

[0066] The straw-fiber-reinforced spray-type phosphogypsum-based fireproof mortar of this embodiment is prepared from the following raw materials according to weight percentage:

[0067]

[0068] Among them, the mass ratio of modified phosphogypsum, modified refractory cement and kyanite mineral powder in the composite cementitious material is 4:2:3, and the modified phosphogypsum is a 5% mass fraction of oxalic acid aqueous solution at 40℃ to dissolve phosphorus Gypsum is agitated and placed in an ultrasonic device for 32 minutes of ultrasound, then filtered, washed, and dried at 38°C; the modified refractory cement is made by mixing nano-silicon carbide and refractory cement with ultrasonic dispersion Processed, wherein the refractory cement is low calcium aluminate refractory cement or calcium magnesium aluminate cement, and the mass ratio of nano-silicon carbide and refractory cement is 1:18; the kyanite in the kyanite mineral powder The quality ratio is 52%.

[0069] In this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com