Semiconductor wafer mounting method and semiconductor wafer mounting apparatus

A film sticking device and semiconductor technology, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as wafer breakage, and achieve the effect of suppressing poor electrical connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

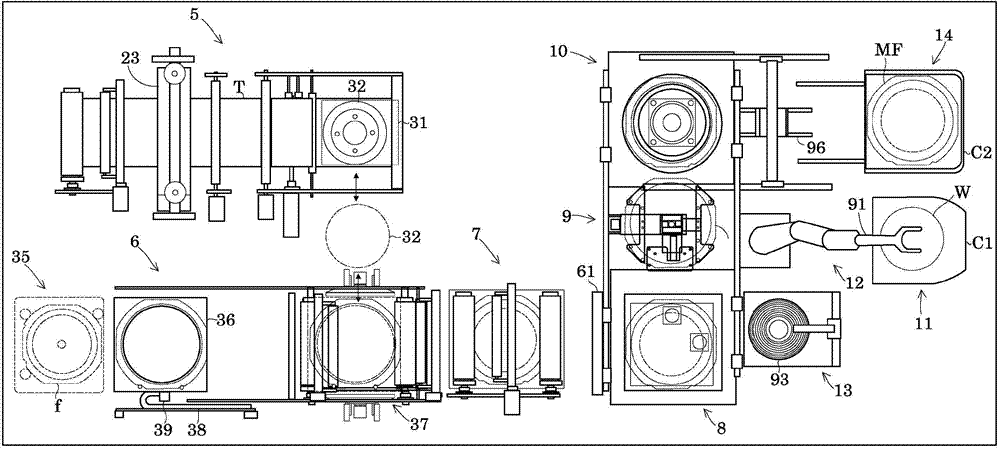

[0057] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0058] semiconductor wafer

[0059] In this embodiment, a semiconductor wafer (hereinafter, simply referred to as a “wafer”) adhered and held by a ring frame with an adhesive tape (dicing tape) for support will be described in detail.

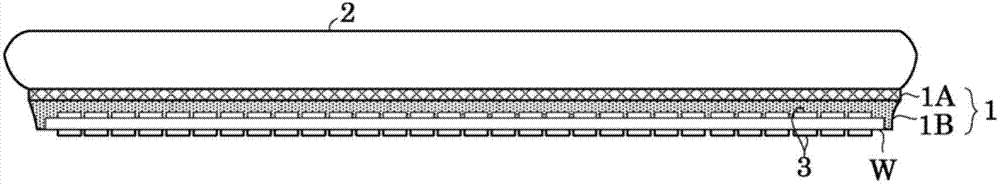

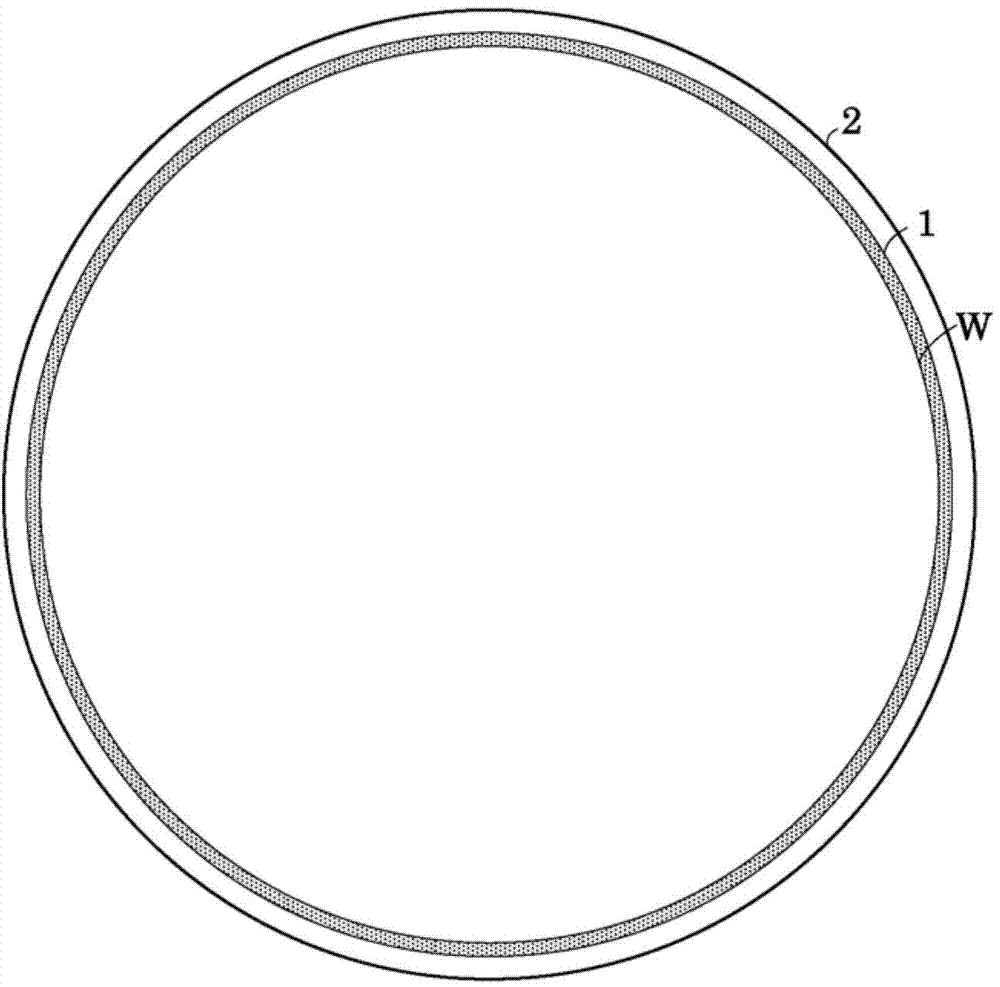

[0060] figure 1 shows a longitudinal sectional view of a semiconductor wafer of the present invention, figure 2 A bottom view of the semiconductor wafer is shown.

[0061] The wafer W is bonded with a support plate 2 for reinforcement by means of a plurality of adhesive layers 1 . Protruding electrodes 3 such as solder balls and bumps are formed on the back surface and the front surface of the wafer W after back grinding. For example, the thickness of the wafer W is 100 μm or less, the thickness of the protruding electrodes 3 and the distance between the protruding electrodes are 100 μm.

[0062] The adhesive layer 1 is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com