A wave soldering system and control method for led plug-in light board

A wave soldering, LED lamp technology, applied in program control, computer control, general control system, etc., can solve the problems of increased pump loss, waste of solder, etc., to reduce waste, reduce wave peaks, and avoid excessive generation of tin dross Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

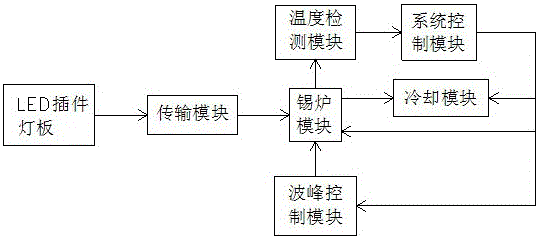

[0022] Below in conjunction with accompanying drawing, structure and working process of the present invention will be further described.

[0023] Such as figure 1 As shown, a wave soldering system for LED plug-in light boards includes a transmission module, a temperature detection module, a tin furnace module, a cooling module, a wave control module, and a system control module. The board is transferred to the tin furnace module. The tin furnace module includes a furnace and a tin furnace nozzle. The bottom of the furnace is provided with a heater, the top is provided with a tin furnace nozzle, and the inside of the furnace is provided with solder. The cooling module is used for cooling welding After the LED plug-in light board, the temperature detection module detects the temperature of the solder in the furnace and the cooling temperature of the cooling module, and the system control module heats the solder in the furnace to a preset temperature according to the data of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com