The preparation method of high-purity cbz-valacyclovir

A technology of valacyclovir and CBZ-L-, which is applied in the field of preparation of high-purity CBZ-valacyclovir, can solve the problem of high product impurity content, and achieve the effects of improving product purity, shortening reaction time and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

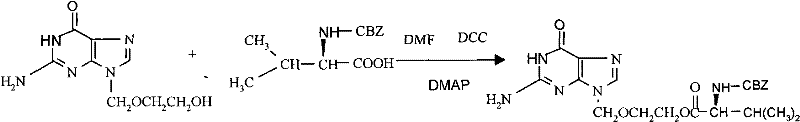

Image

Examples

Embodiment 1

[0031] Put 800ml of N,N-dimethylformamide into the reaction flask, add 25g of acyclovir, 50g of N-benzyloxycarbonyl-L-valine and 0.5g of 4-dimethylaminopyridine under stirring, and cool to 10℃ Hereinafter, 40g of dicyclohexylcarbodiimide was added, and after the reaction was kept at 5-10°C for 2 hours, the temperature was raised to 20-25°C within 55-65 minutes, and the reaction was kept at temperature for 15 hours. The solid in the reaction system (dicyclohexylurea) was filtered off with suction, and the filtrate was concentrated under reduced pressure to obtain an oily substance. 300ml of ethanol was added to heat to dissolve the concentrate. After the solution was cleared, it was cooled to -5 to 0°C for crystallization for 10 hours. After suction filtration, the obtained solid was heated and dissolved with 250 ml of ethanol, and then cooled to -5 to 0°C for 10 hours to crystallize. Suction filtration, the obtained solid was dissolved by heating with 100ml of N,N-dimethylforma...

Embodiment 2

[0033] Put 800ml of N,N-dimethylformamide into the reaction flask, add 25g of acyclovir, 50g of N-benzyloxycarbonyl-L-valine and 0.5g of 4-dimethylaminopyridine under stirring, and cool to 10℃ Hereinafter, 40g of dicyclohexylcarbodiimide is added, and after the reaction is kept at 5-10°C for 1 hour, the temperature is raised to 20-25°C in 115-125 minutes, and the reaction is kept at temperature for 15 hours. The solid in the reaction system (dicyclohexylurea, a byproduct of the reaction) was filtered off with suction, the filtrate was concentrated under reduced pressure to obtain an oily substance, 300ml of ethanol was added to heat to dissolve the concentrate, dissolved and then cooled to -5°C for crystallization for 10 hours. Suction filtration, the obtained solid was dissolved by heating with 100ml of N,N-dimethylformamide, and then the obtained N,N-dimethylformamide solution was added to 600ml of hot water at a temperature of 55~65℃, and Stir at 55°C for 30 minutes, filter ...

Embodiment 3

[0035] Put 800ml of N,N-dimethylformamide into the reaction flask, add 25g of acyclovir, 50g of N-benzyloxycarbonyl-L-valine and 0.5g of 4-dimethylaminopyridine under stirring, and cool to 5℃ Hereinafter, 40g of dicyclohexylcarbodiimide is added, and after the reaction is kept at 0-5°C for 2 hours, the temperature is raised to 20-25°C in 55-65 minutes, and the reaction is kept at the temperature for 15 hours. The solid (dicyclohexylurea) in the reaction system was filtered off with suction, and the filtrate was concentrated under reduced pressure to obtain an oily substance. 300ml of ethanol was added to heat to dissolve the concentrate, dissolved and cooled to 0°C for crystallization for 10 hours. After suction filtration, the obtained solid was dissolved by heating with 250 ml of ethanol, and then cooled to 0°C to crystallize for 10 hours. Suction filtration, the obtained solid was dissolved by heating with 100ml of N,N-dimethylformamide, and then the obtained N,N-dimethylfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com