Full-automatic postprocessing device for compressor casing casting

A compressor casing, fully automatic technology, applied in the field of casting, can solve the problems of difficult management, process equipment that cannot meet the quality requirements of production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

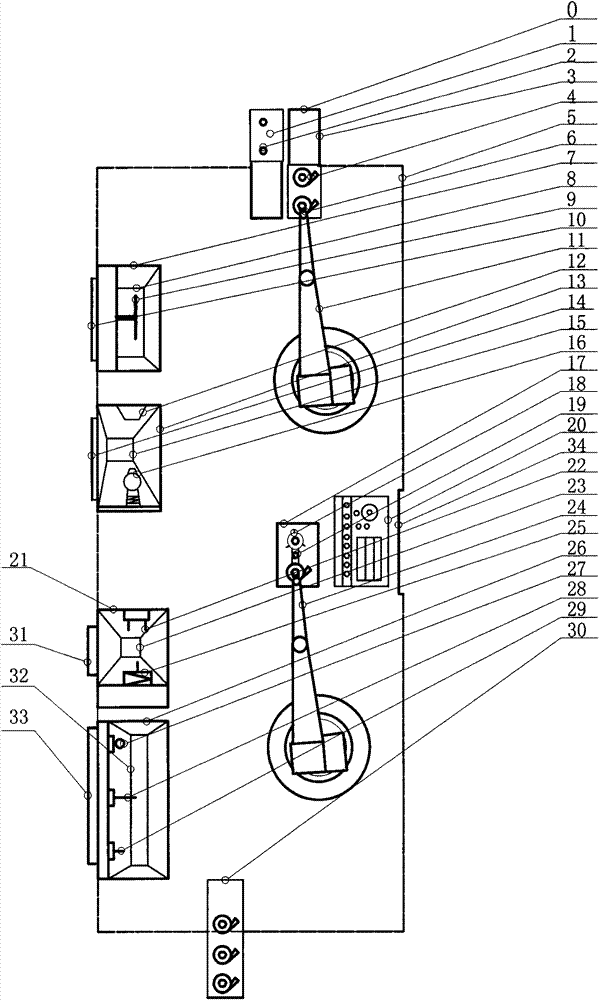

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] figure 1 Among them, including reciprocating feeding frame 0, sliding table 1, positioning frame 2, rodless cylinder guide rail 3, casting 4, fence 5, mechanical claw 6, cutting frame 7, lower hopper 8, cutting blade 9, and discharge Car 10, mechanical pick-up buttock 11, shock table 12, sand shaker frame 13, sand discharge car 14, sand hopper 15, vibration head 16, transfer shelving table 17, positioning table 18, rotating frame 19, console 20, punching Hole frame 21, positioning chuck 22, pin-out bucket 23, pick-up buttock 24, drilling machine 25, deburring frame 26, grinding head machine 27, deburring milling head 28, spare milling head 29, feeding conveyor 30 , Outlet car 31, powder outlet hopper 32, powder outlet car 33, fence door 34, etc.

[0015] Such as figure 1 As shown, the present invention is a post-processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com