Tech. for baking dry quartz sand by rotating drum

A technology for drying quartz sand and quartz sand, which is applied in drying, drying machines, drying solid materials, etc., and can solve problems such as inability to meet modern production requirements, inability to pick up quartz sand, uneven drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

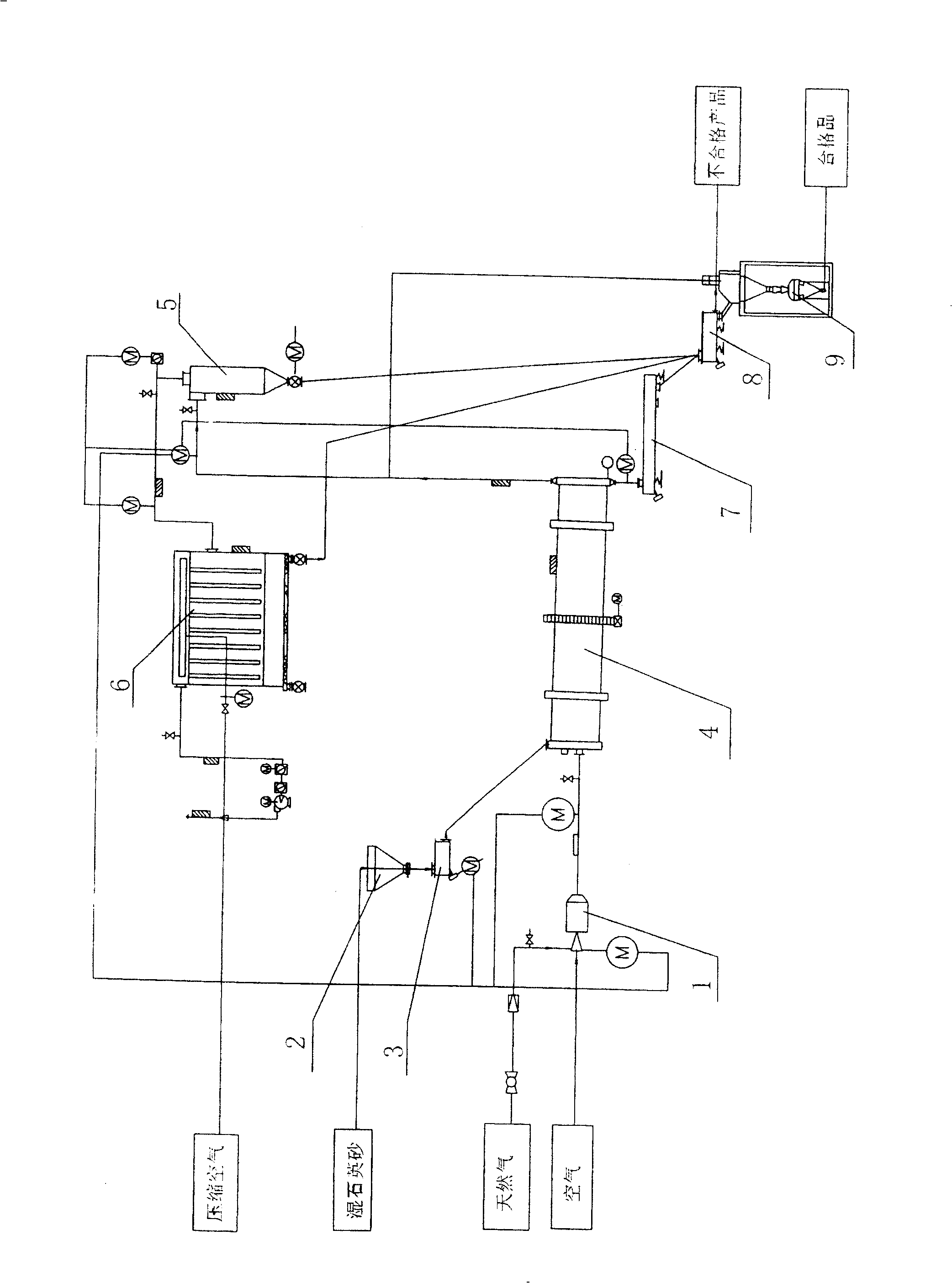

[0013] Example 1: The process steps are as shown in the accompanying drawings. The natural gas and combustion-supporting air are mixed and sent to the gas-fired flue gas furnace 1. After burning in the flue gas furnace 1, high-temperature flue gas at 700°C is produced and enters the rotary cylinder dryer 4. The wet quartz The sand is sent into the rotary drum dryer 4 through the buffer silo 2 under the action of the vibrating feeder 3 . At the same time, the compressed air is also sent into the rotary cylinder dryer 4. The wet quartz sand is evenly lifted up by the 4 inner grid plates of the rotary cylinder dryer. After full contact, a large amount of water in the wet quartz sand is released, and the high-temperature hot flue gas becomes flue gas at about 100 ° C and a large amount of water vapor. After being purified by the cyclone dust collector 5 and the bag filter 6, it is drawn out by the induced draft fan and discharged into the atmosphere through the chimney; the dried ...

Embodiment 2

[0014] Example 2: The process steps are as shown in the accompanying drawings. The natural gas and combustion-supporting air are mixed and sent to the gas-fired flue gas furnace 1. After burning in the flue gas furnace 1, high-temperature flue gas of 780°C is produced and enters the rotary cylinder dryer 4. The wet quartz The sand is sent into the rotary drum dryer 4 through the buffer silo 2 under the action of the vibrating feeder 3 . At the same time, the compressed air is also sent into the rotary cylinder dryer 4. The wet quartz sand is evenly lifted up by the 4 internal grid plates of the rotary cylinder dryer, and after full contact, a large amount of moisture in the wet quartz sand is released, and the high-temperature hot flue gas becomes flue gas at about 130°C and a large amount of water vapor After being purified by the cyclone dust collector 5 and the bag filter 6, it is drawn out by the induced draft fan and discharged into the atmosphere through the chimney; the...

Embodiment 3

[0015] Example 3: The process steps are as shown in the accompanying drawings. Natural gas and combustion-supporting air are mixed and sent to the gas-fired flue gas furnace 1. After burning in the flue gas furnace 1, high-temperature flue gas at 850°C is produced and enters the rotary cylinder dryer 4. The wet quartz The sand is sent into the rotary drum dryer 4 through the buffer silo 2 under the action of the vibrating feeder 3 . At the same time, the compressed air is also sent into the rotary cylinder dryer 4. The wet quartz sand is evenly raised by the 4 internal grid scooping plates of the rotary cylinder dryer. After full contact, a large amount of water in the wet quartz sand is released, and the high-temperature hot flue gas becomes flue gas at about 150 ° C and a large amount of water vapor. After being purified by the cyclone dust collector 5 and the bag filter 6, it is drawn out by the induced draft fan and discharged into the atmosphere through the chimney; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com