Novel screw hitting device

A new type of technology for screwing, applied in screwdrivers, metal processing, wrenches, etc., can solve the problems of long time consumption and low work efficiency when screwing devices work, and achieve the effect of solving long time consumption, improving work efficiency and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

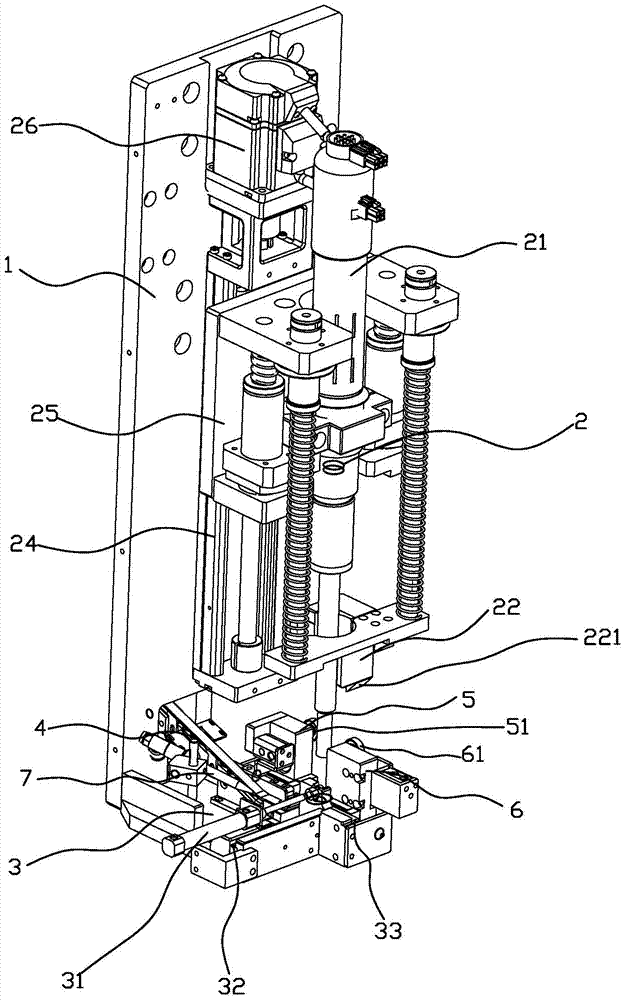

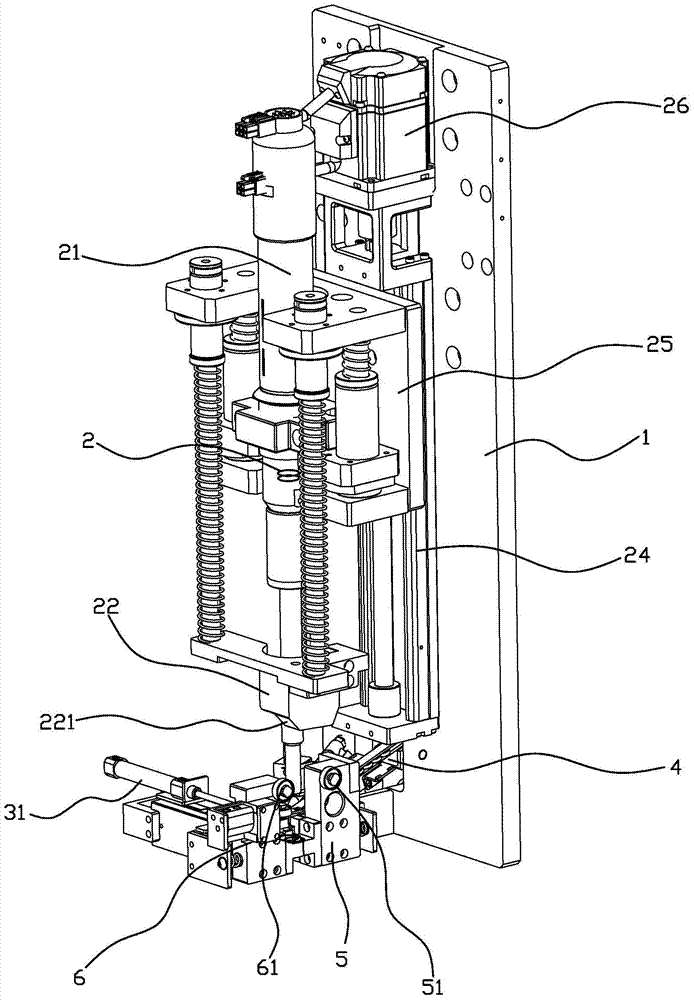

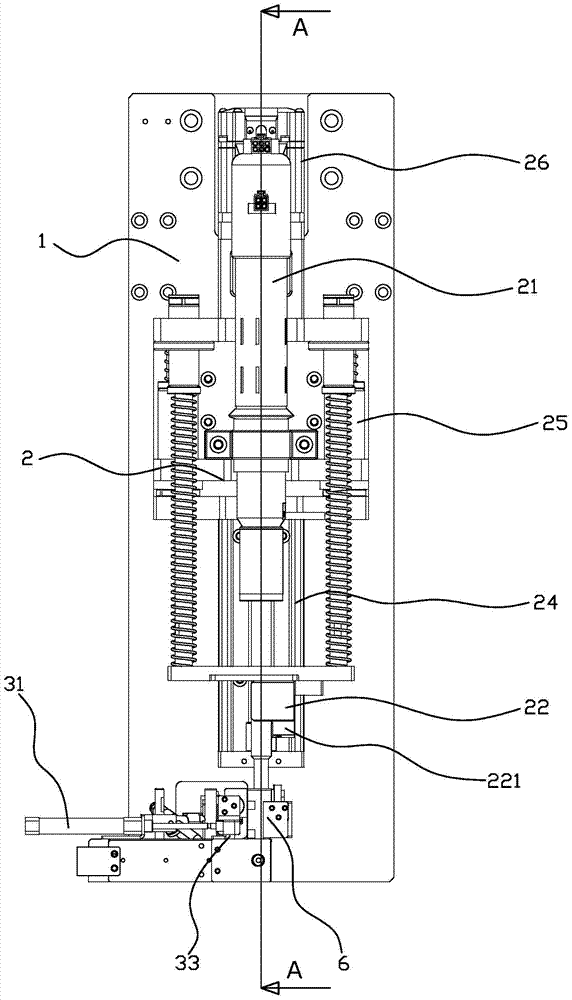

[0028] refer to Figure 1-12 , a novel screwing device, comprising a main mounting plate 1, on which a screwing assembly 2 is installed, and the screwing assembly 2 includes a screw gun 21 and a slope surface on both sides thereof 221 of the lower pressing block 22, the inside of the screw gun 21 is provided with a buffer spring 23, the lower part of the main mounting plate 1 is fixedly connected with the bottom mounting plate 3, and the bottom mounting plate 3 is directly or indirectly provided with a screw delivery assembly 4 , the first elastic slider assembly 5 and the second elastic slider assembly 6, the first elastic slider assembly 5 and the second elastic slider assembly 6 are respectively provided with slope surfaces 221 which are matched to the two sides of the above-mentioned lower pressing block 22 The first pulley 51 and the second pulley 61, the second screw slider assembly 6 is also provided with a screw recess 60 for moving the screw.

[0029] The bottom moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com