Plastic extruder fused strip detection method and detector

A technology of plastic extruder and detection method, which is applied in the research field of plastic extrusion granulation, can solve the problems of rising use cost, lack of popularization, and impractical plastic granulation, so as to improve output rate and production Efficiency, high promotion and application prospects, and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

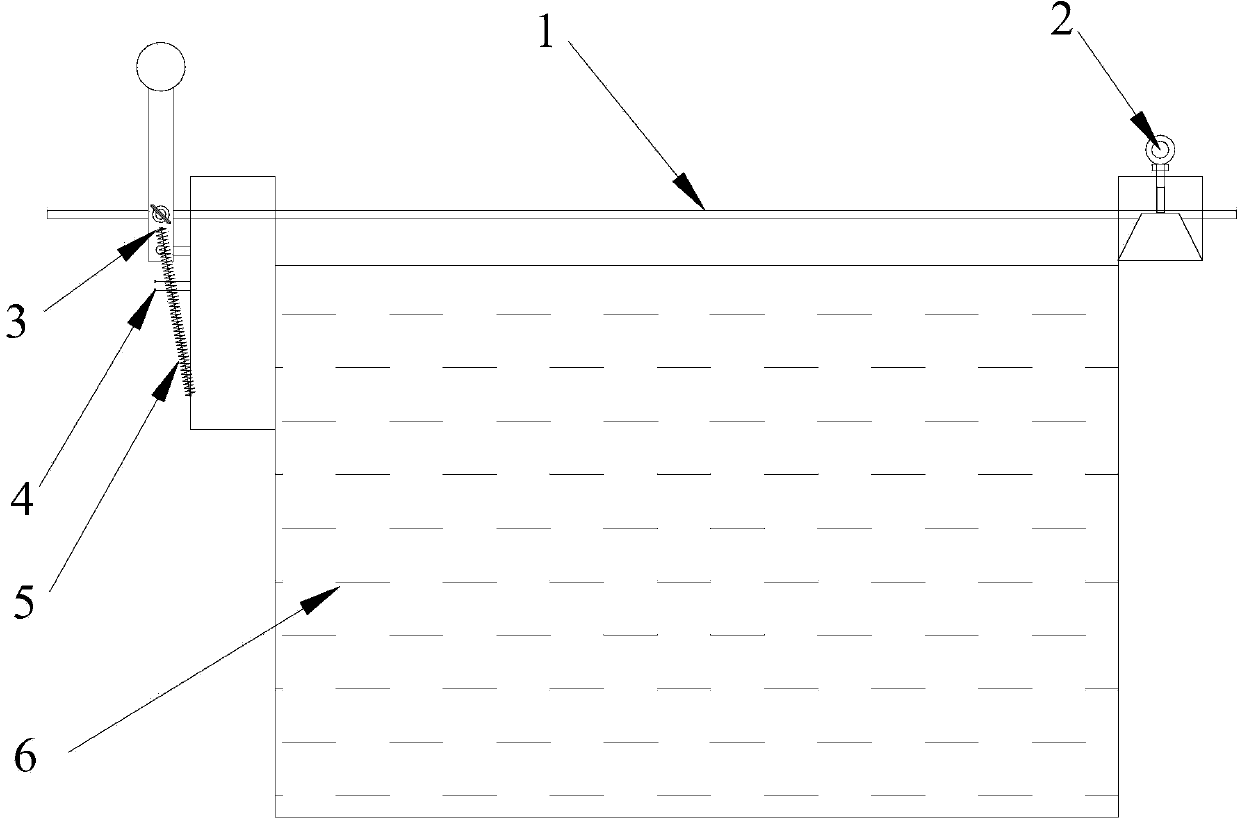

[0027] The detection method and detection device for the blown strip of the plastic extruder in this embodiment are auxiliary detection methods and detection devices applied in the process of plastic extrusion and granulation. The structure of the device is as follows figure 1 As shown, it includes a material strip 1 for detection, a material strip bracket, two contact detectors 4 and an audible and visual alarm device. The material of the detection material strip is the material of the product being produced by the current plastic extruder or is compatible with the product being produced. Materials with similar melting properties; the material strip support includes a locking device 2 and a tensioning device 3. When the detection is to be started, the two ends of the detection material strip 1 are respectively fixed on the locking device 2 and the tensioning device 3, and the tensioning device 3 is tightened. A spring 5 is provided at the device to apply an upward or downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com