Novel front and rear frame hinged structure for loaders

A technology of a loader and a rear frame, applied in the field of machinery, can solve the problems of high cost, poor manufacturability, complex frame structure, etc., and achieve the effects of simplified manufacturing process, low cost and small turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

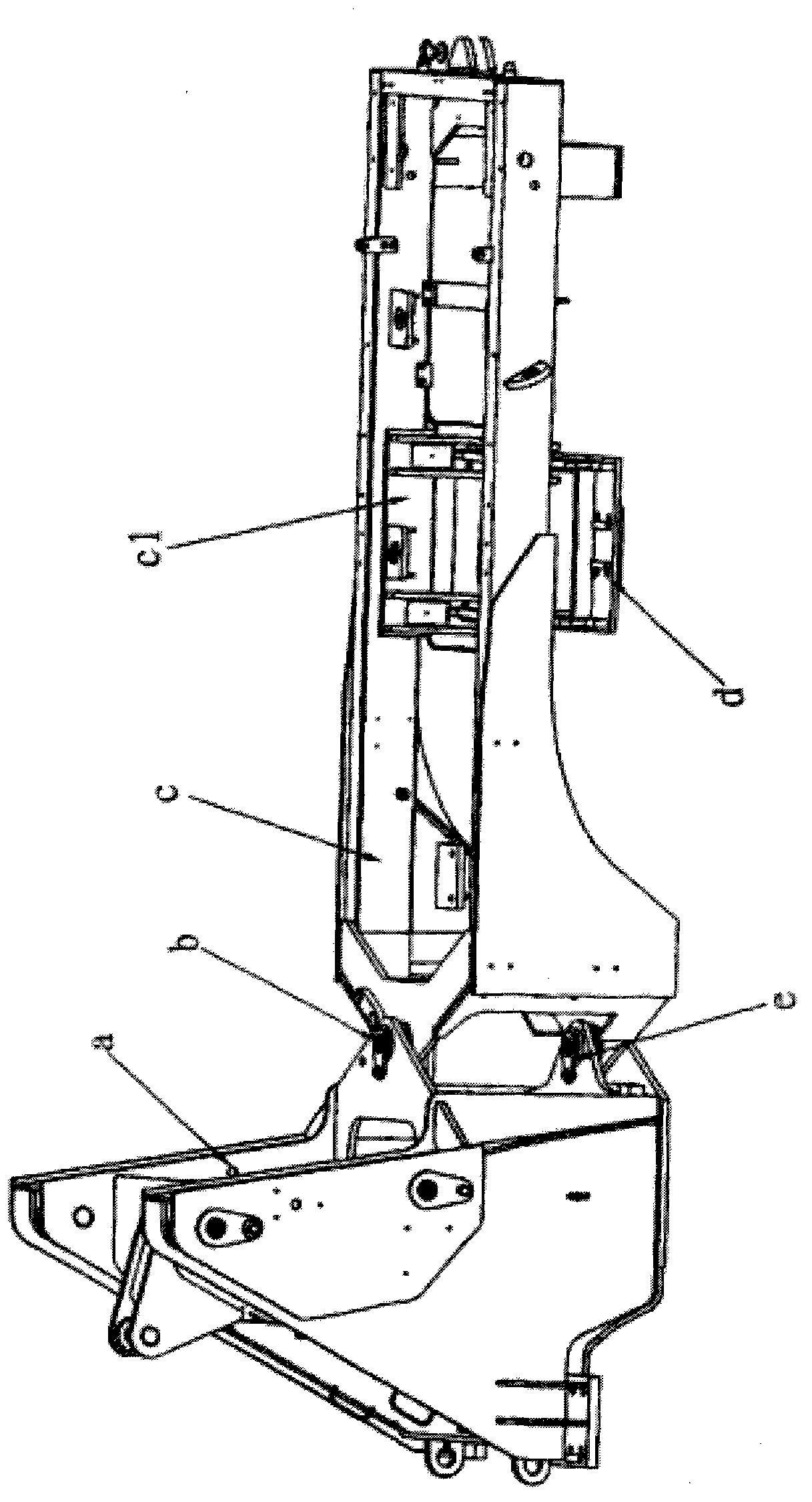

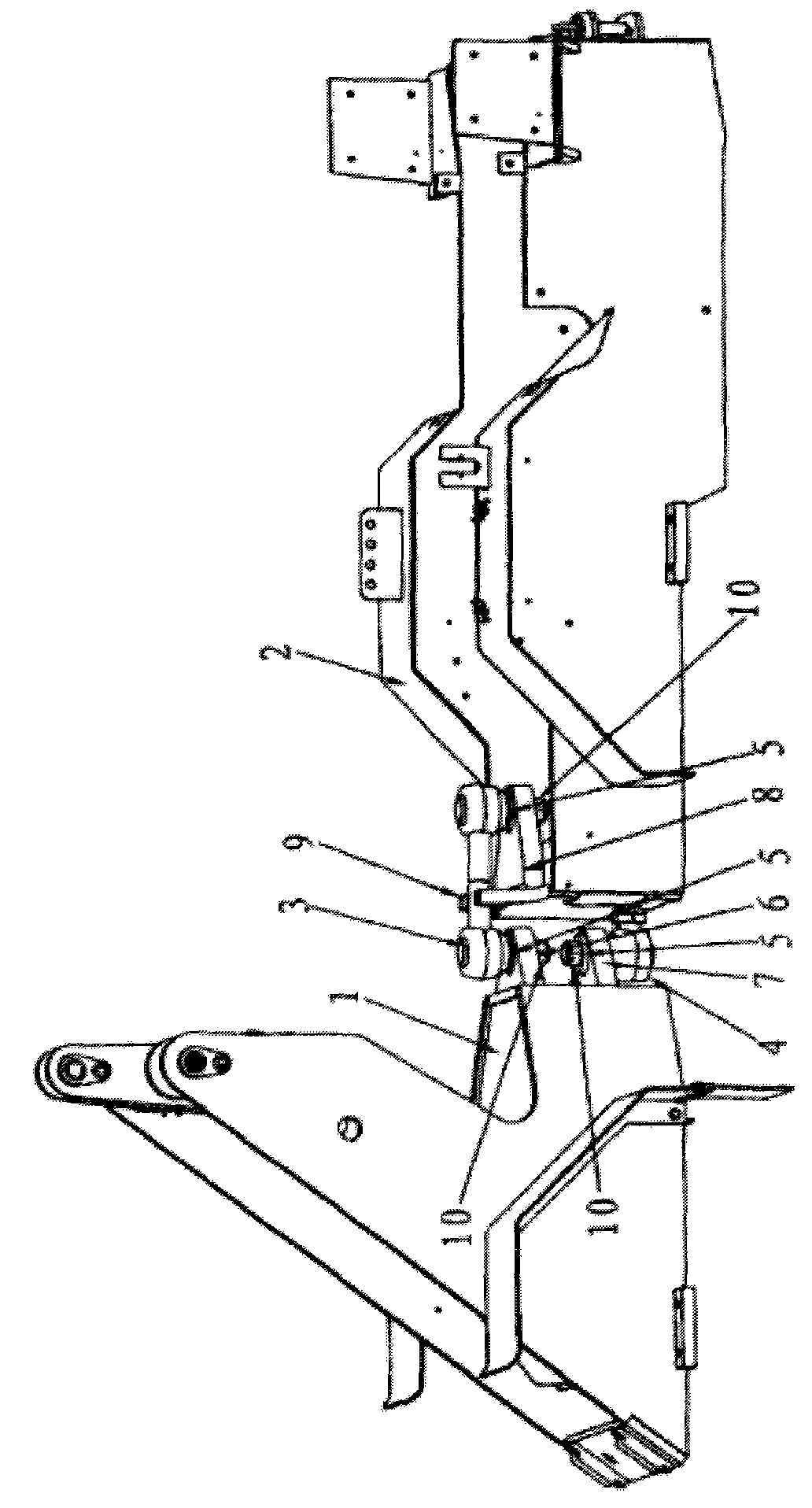

[0016] Such as figure 1 As shown, the present invention is a novel loader front and rear frame hinged structure, which includes a front frame 1, a rear frame 2, an upper rod ball 3, a lower rod ball 4, a taper sleeve 5, and a front upper hinge plate 6. , the front lower hinged plate 7, the rear hinged puller 8 and the limiting plate 9.

[0017] The front frame 1 is connected with the rear frame 2 through the upper link ball 3 and the lower link ball 4 .

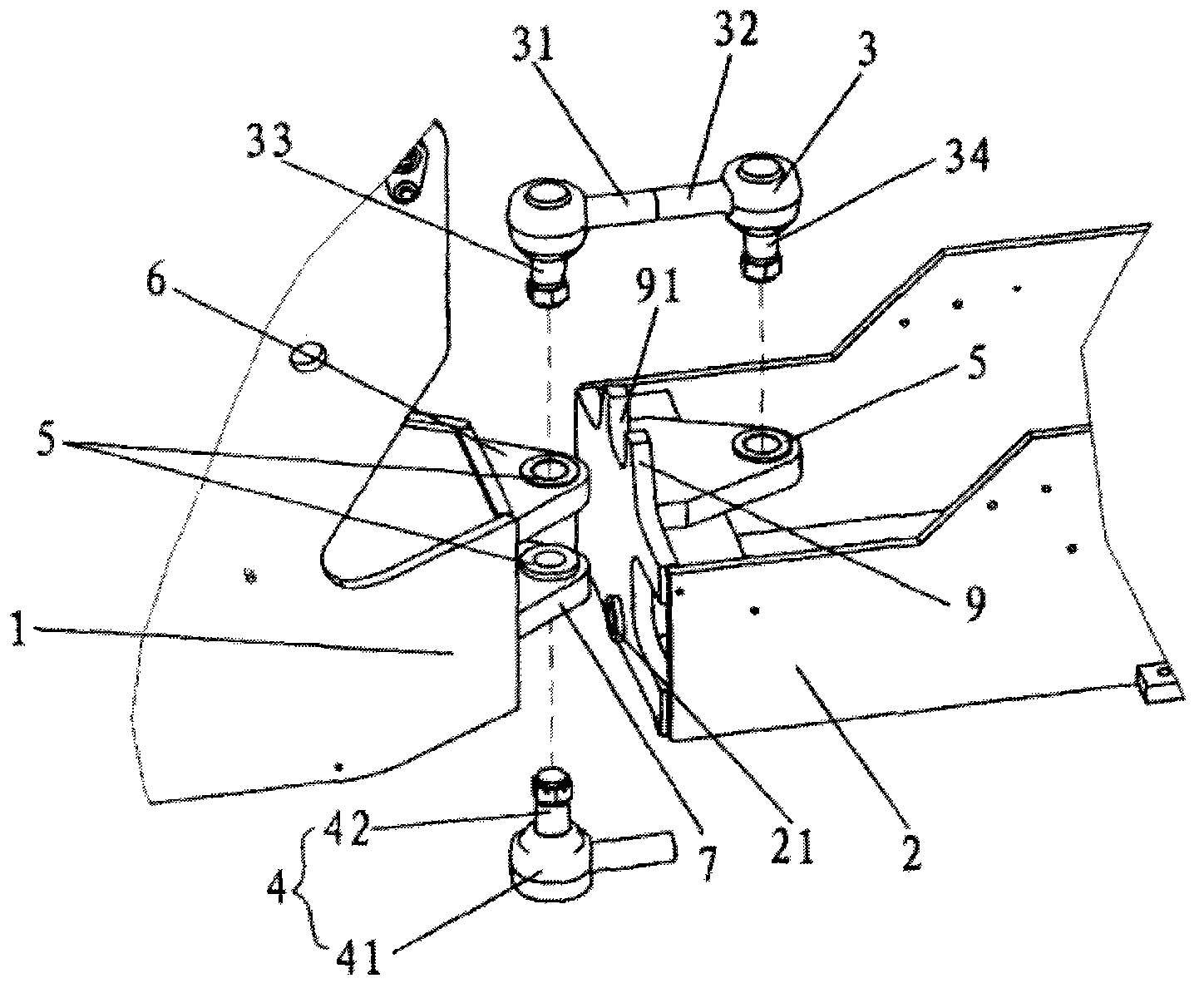

[0018] Such as Figure 4 As shown, the pull down rod head 4 is composed of a swing rod 41 and a pin shaft 42 . The inner end of the swing rod 41 is rotatably socketed on the top of the pin shaft 42, which is connected by a ball joint and has a self-lubricating structure inside. The free end of the swing rod 41 and the free end of the pin shaft 42 intersect perpendicularly.

[0019] Such as image 3 As shown, the pull-up rod head 3 is composed of two swing rods 31 , 32 and two pin shafts 33 , 34 . The inner ends of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com