Clutch master cylinder mounting structure

A technology of clutch master cylinder and installation structure, which is applied to clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of difficult installation and disassembly of the clutch master cylinder, and achieve the effect of convenient assembly and maintenance, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment the present invention is described in detail as follows:

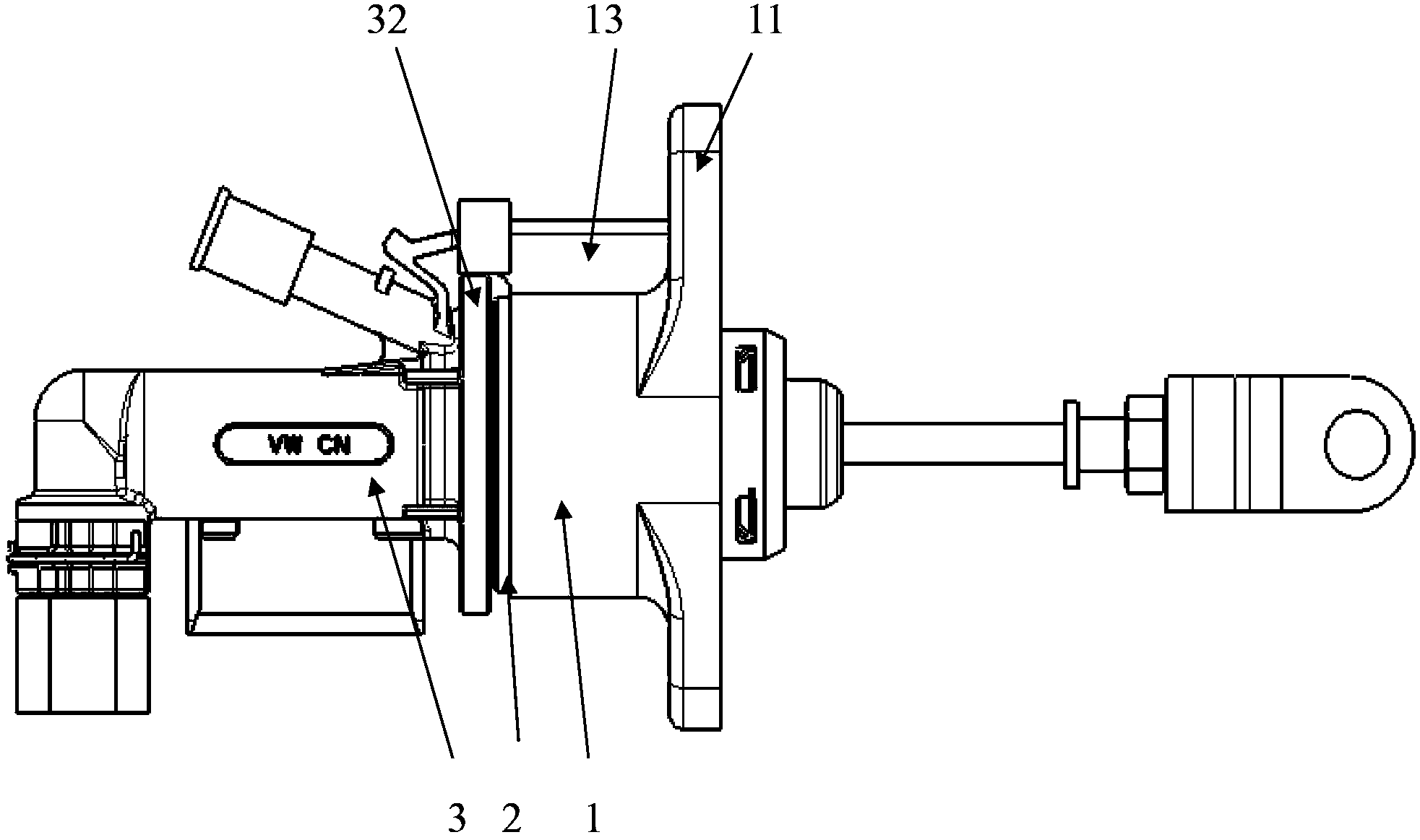

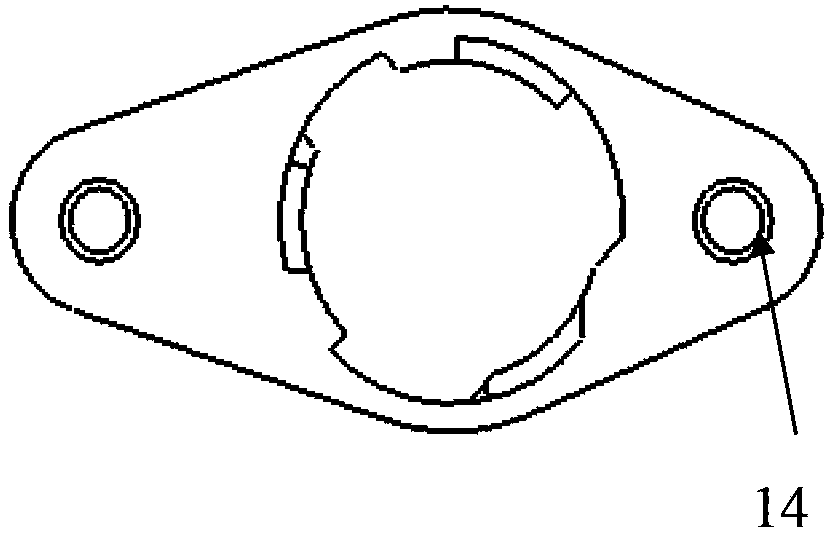

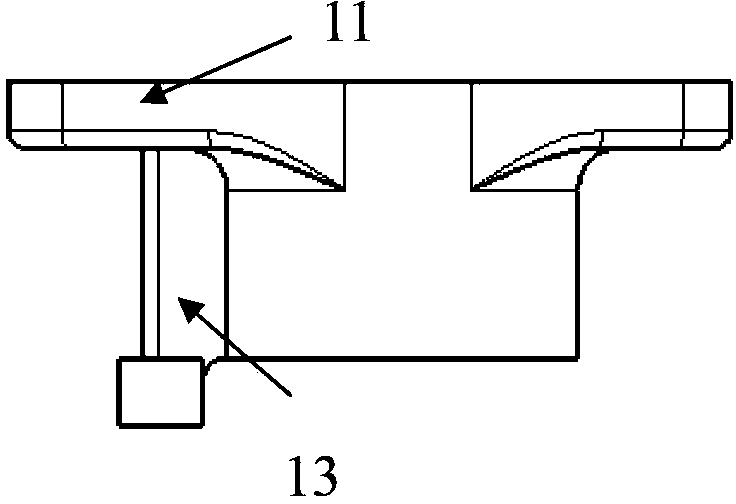

[0026] Such as figure 1 As shown, the clutch master cylinder 3 is connected to the vehicle body (not shown in the figure) through the connecting part 11 of the mounting pad 1, and the connecting part 11 of the mounting pad 1 is connected to the vehicle body through bolts (not shown in the figure) , the bolt passes through the mounting hole 14 of the connecting part 11 (such as Figure 2A As shown), the holes on the body are matched with the nuts. Those of ordinary skill in the art can imagine that the connection portion 11 of the mounting pad 1 can also be connected to the vehicle body through other connection methods, such as fixed connections such as riveting and welding or connection methods such as slots. However, the use of bolt connection is convenient for assembly and disassembly, and the fixing effect is good. Although in this embodiment, the connecting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com