A steering wheel damper

A steering wheel and damper technology, which is applied to the steering control and handwheels installed on the car, can solve the problems of friction wear, high manufacturing cost, and large volume of the steering wheel damper, and achieve simple production and processing and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

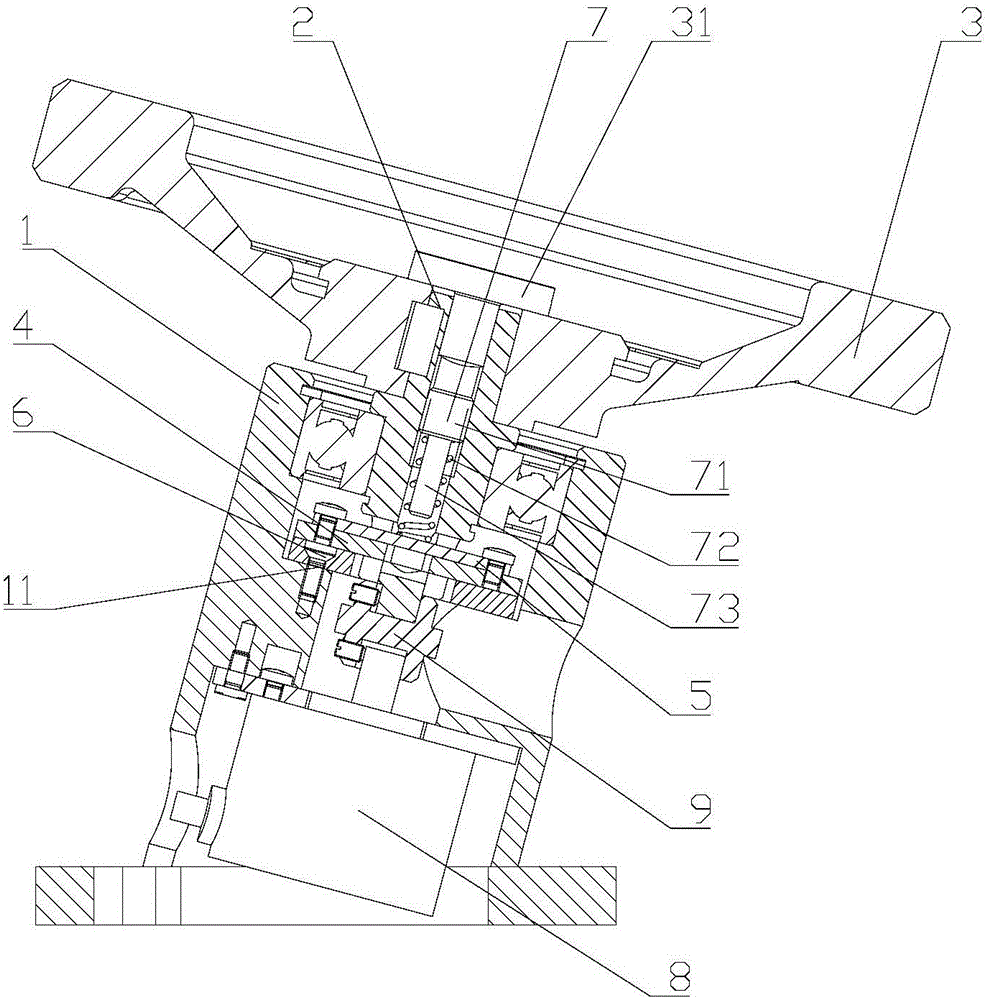

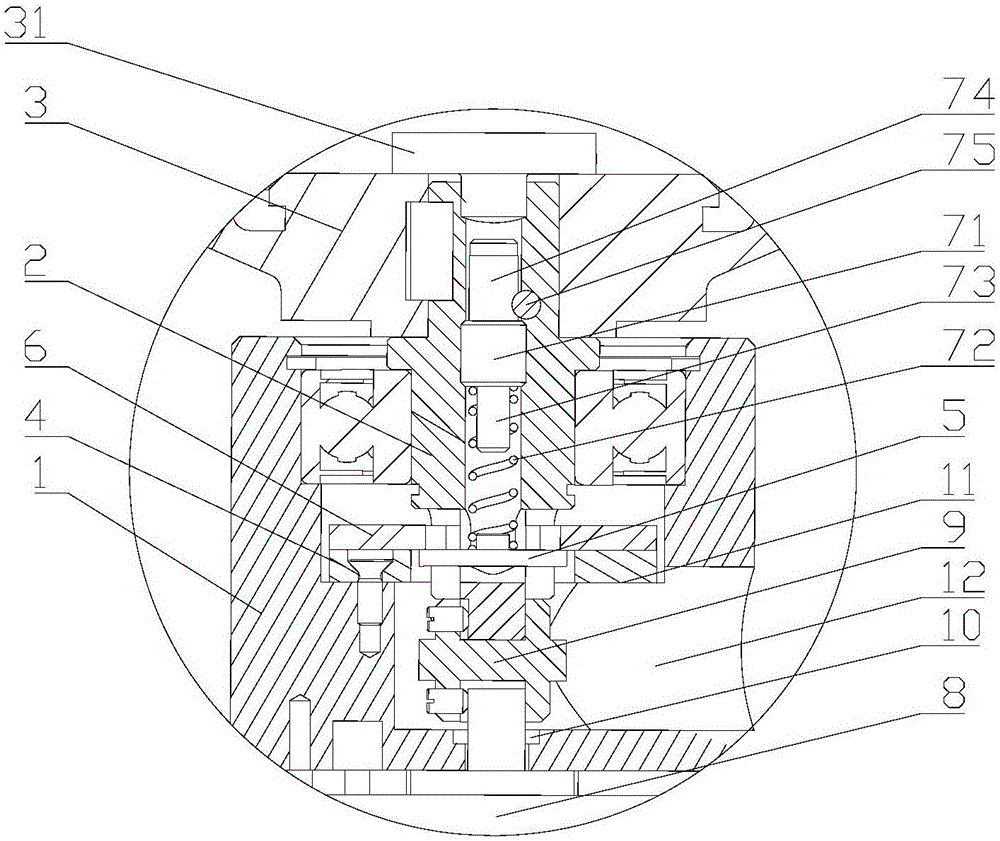

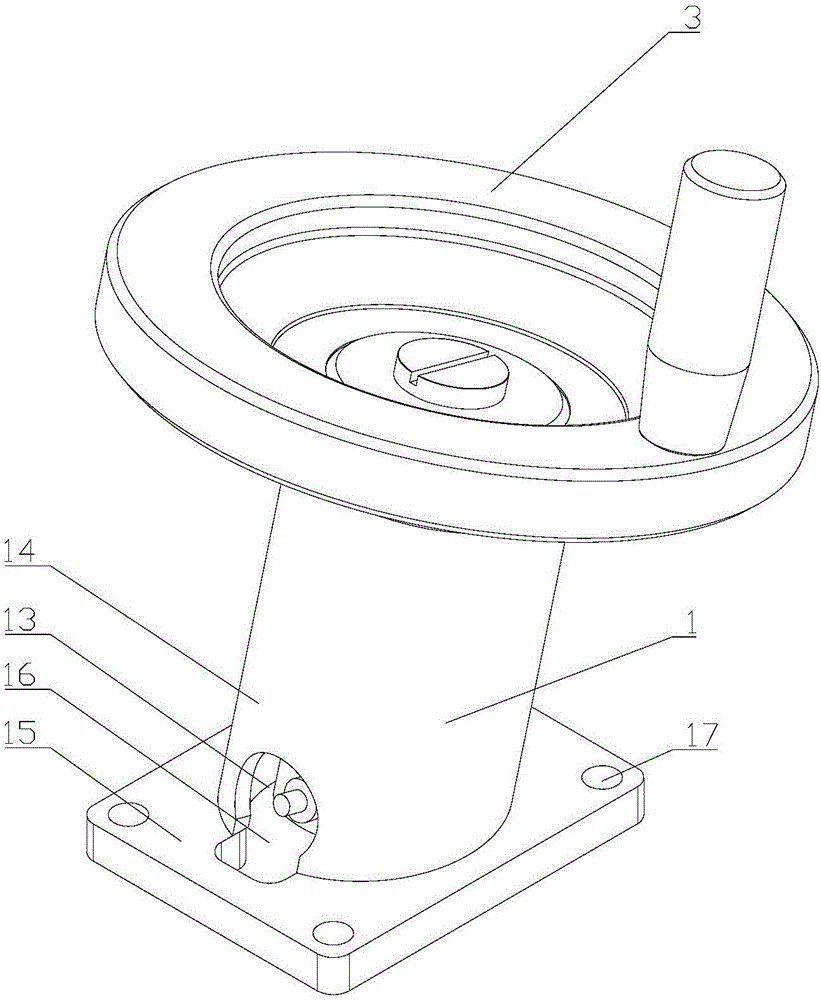

[0031] refer to figure 1 , image 3 As shown, a steering wheel damper provided by the present invention includes a hollow support base 1, a rotating shaft 2 passing through the support base 1, the rotating shaft 2 and the support base 1 can be connected through a bearing, and fixed with a circlip, A steering wheel 3 or an industrial handwheel etc. are installed on the rotating shaft 2, a step surface 11 is provided in the support seat 1, a static friction plate 4 is installed on the step surface 11, and a guide hole 21 is arranged on the rotating shaft 2 radially, the guide hole 21 It can be a waist-shaped hole or a rectangular hole. A mounting block 5 that can move axially along the rotating shaft 2 is perforated in the guide hole 21. The mounting block 5 is connected with a set of dynamic friction plates 6 that are arranged on the rotating shaft 2. The rotating shaft 2 The central position is also provided with a first installation hole 22 communicating with the guide hole ...

Embodiment 2

[0038] refer to figure 2 , Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that a gear 74 is integrally provided on the top of the compression screw 71, and a second mounting hole 24 is provided at a position opposite to the gear on the rotating shaft 2, and a second mounting hole 24 is provided on the steering wheel 3 with the second gear. The position opposite to the mounting hole 24 is provided with an operation hole. A worm 75 is arranged in the second mounting hole 24. The worm 75 can only rotate in the rotating shaft 2. The end of the worm 75 is provided with a groove for rotating the worm 75. The groove can be a cross cut or a straight cut 76, which is used to facilitate the rotation of the screwdriver. Utilize the rotating worm 75 to drive the gear 74 to rotate, and finally drive the compression screw 71 to rotate and compress the dynamic friction plate 6. When it is necessary to adjust the internal friction damping, only need to use a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com