Mounting and dismounting machine for air bushing of blast furnace

A technology for dismantling machines and air jackets, which is applied in the direction of the tuyere, which can solve the problems of personal injury accidents, high labor intensity, and low labor efficiency, and achieve the effects of reducing labor intensity, simple operation, and eliminating personal injury accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

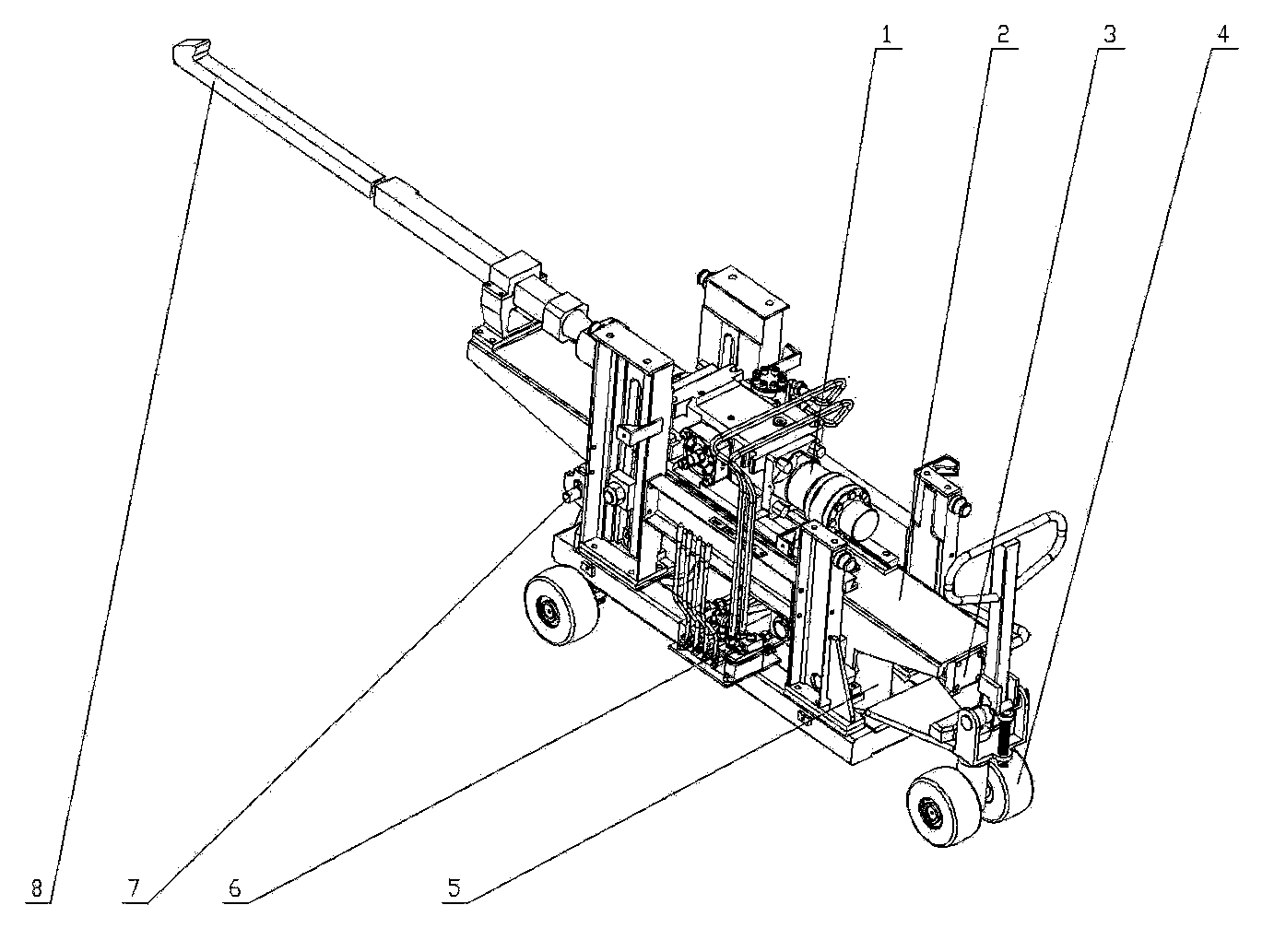

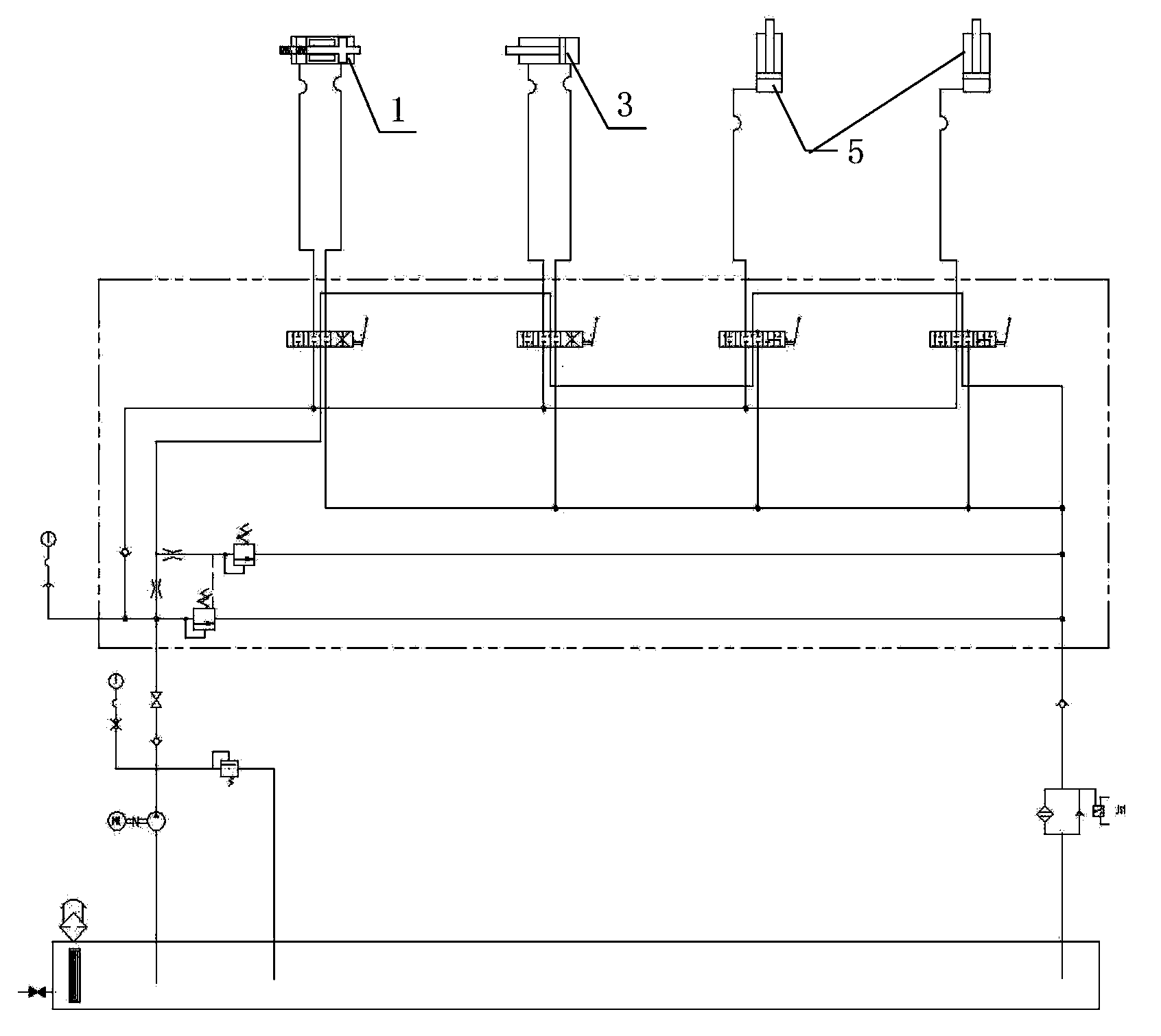

[0009] The structure of the present invention is as figure 1 As shown, a blast furnace air jacket installation and disassembly machine is provided with a striking mechanism 1 and a positioning device 7. The working platform 2 is connected with the horizontal oil cylinder 3 and the lifting oil cylinder 5. The hook 8 is installed at the front of the working platform, and Organization 1 cooperates.

[0010] In order to facilitate the movement of the machine, the blast furnace wind cover installation and disassembly machine is also provided with a traveling mechanism 4, which is a manual hydraulic trolley.

[0011] The striking mechanism 1 is a hydraulic impactor.

[0012] The working principle of the present invention is as follows: the power of the equipment is provided by an external hydraulic system, first use the industrial handling equipment forklift or use the walking mechanism 4 of the device to manually move the equipment to the working position, fix the equipment and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com