Secondary fiber fine screen system

A secondary fiber, fine screening technology, applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of quality reduction, poor screening efficiency, fiber loss, etc., to reduce fiber loss, ensure pulp quality, high fiber quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

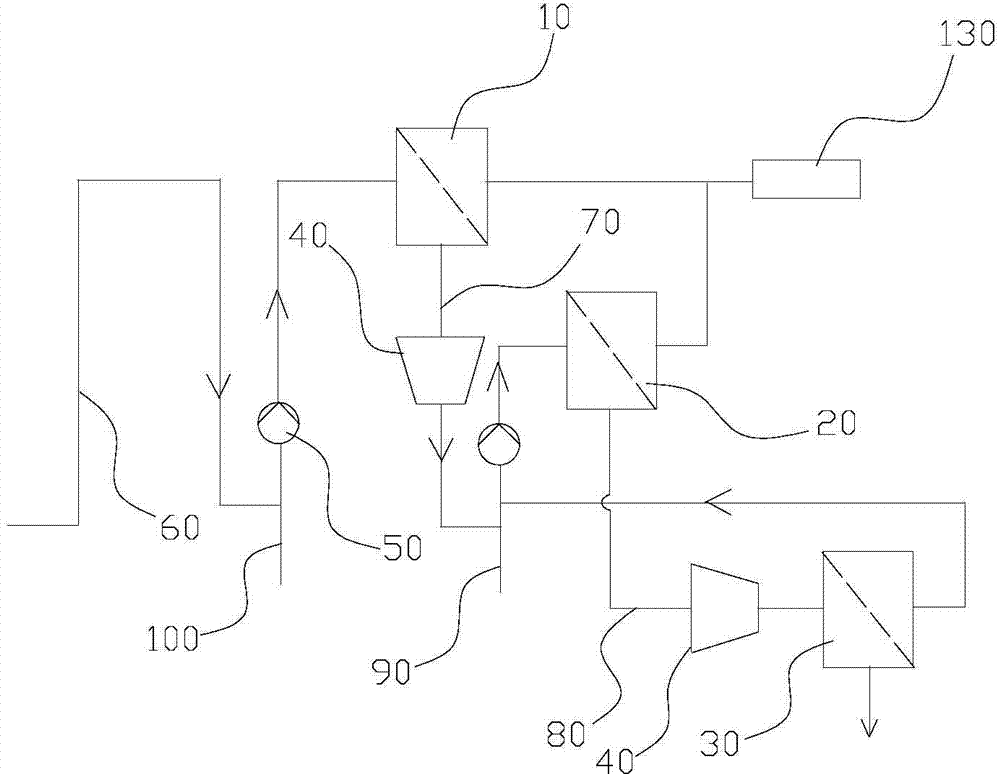

[0030] Such as figure 1 As shown, a secondary fiber fine screening system includes a first fine screening device 10, a second fine screening device and a third fine screening device 30, the input end of the first fine screening device 10 is connected with an input pipeline 60, and the first fine screening device 10 is connected with an input pipeline 60. The slag discharge end of the first fine sieve device 10 and the slurry discharge end of the third fine sieve device 30 are all connected to the input end of the second fine sieve device 20 through pipelines, and the slag discharge end of the second fine sieve device 20 is also connected through the pipeline. The road is connected to the input end of the third fine screening device 30, and the pipeline between the slag discharge end of the first fine screening device 10 and the input end of the second fine screening device 20 is marked as the first delivery pipeline 70, and the pipeline between the second fine screening device ...

Embodiment 2

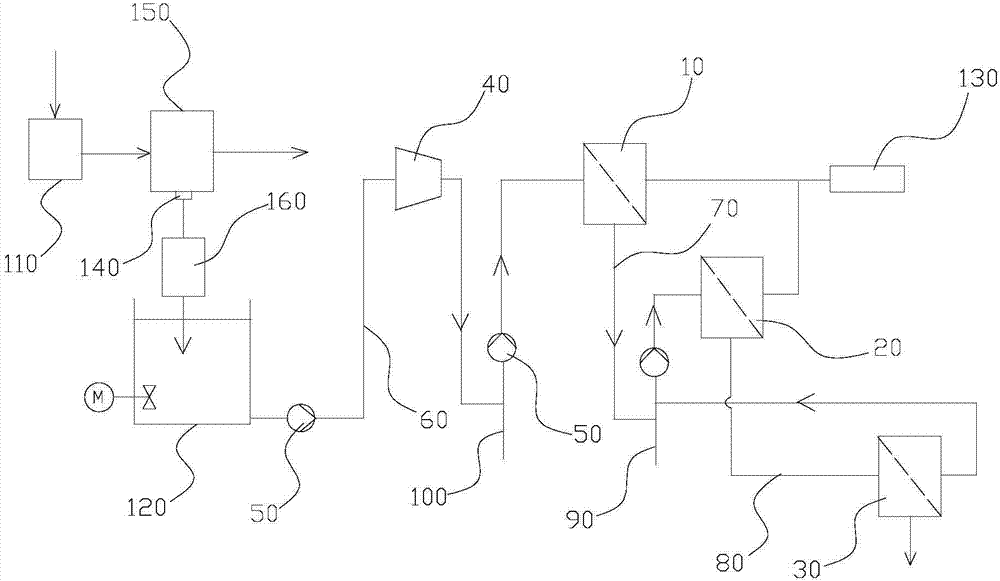

[0040] Such as figure 2 As shown, a secondary fiber fine screening system includes a first fine screening device 10, a second fine screening device 20 and a third fine screening device 30, the input end of the first fine screening device 10 is connected with an input pipeline 60, The slag discharge end of the first fine sieve device 10 and the slurry discharge end of the third fine sieve device 30 are all connected to the input end of the second fine sieve device 20 through pipelines, and the slag discharge end of the second fine sieve device 20 is also passed through The pipeline is connected to the input end of the third fine sieve device 30, and the pipeline between the slag discharge end of the first fine sieve device 10 and the input end of the second fine sieve device 20 is denoted as the first delivery pipeline 70, and the pipeline with the second fine sieve device 20 The pipeline between the slag discharge end of the second fine screening device 20 and the input end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com