Combined cashmere carding machine

A carding machine and cashmere technology, which is applied in the field of cashmere machinery, can solve the problems such as the need for further improvement of no plush, narrow process adjustment range, low one-time extraction rate, etc., and achieves small fiber loss, high degree of automation and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

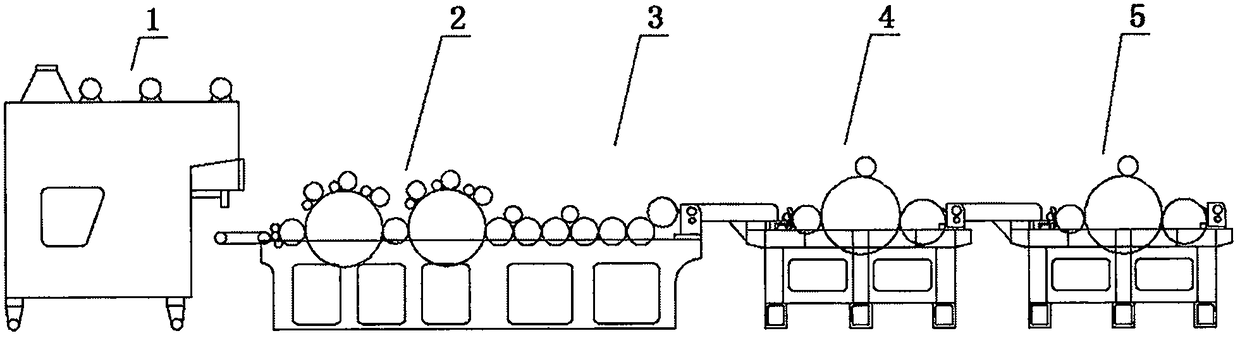

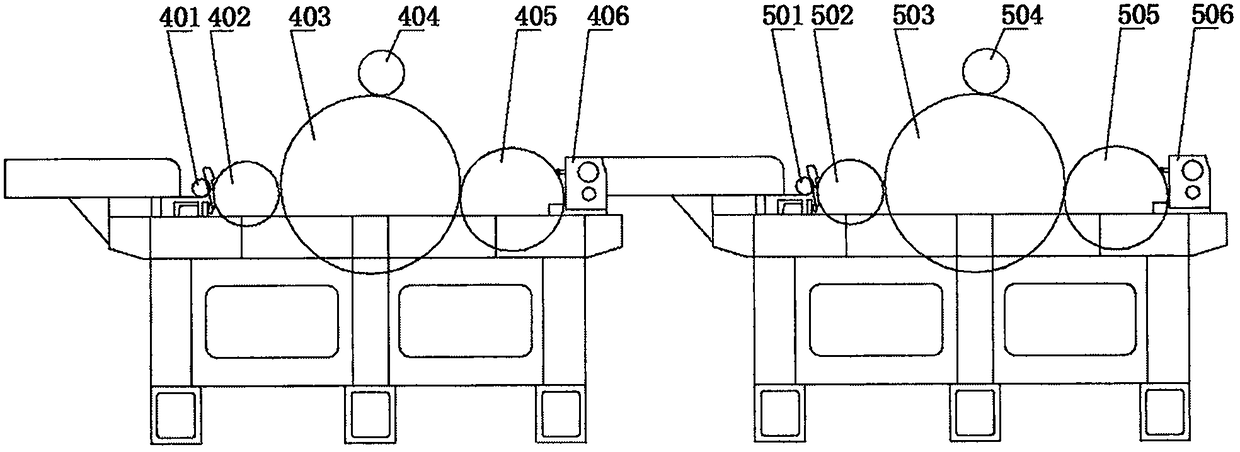

[0014] Such as Figure 1 to Figure 3 Shown, a kind of combined cashmere carding machine, comprises wool feeder 1, opener 2, throws away rough machine 3, the first carding machine 4 and the second carding machine 5;

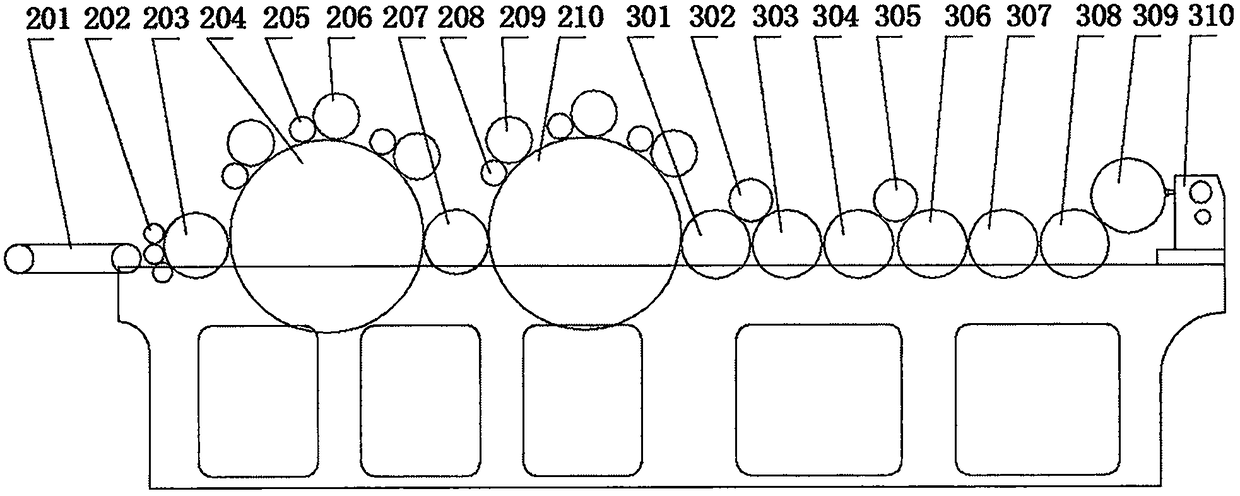

[0015] The opening machine includes a first opening unit and a second opening unit, the first opening unit includes a No. 1 opening cylinder 204 and three pairs of working rollers 206 arranged on the No. 1 opening cylinder 204 The working mechanism composed of the stripping roller 204 is provided with a feeding curtain 201, three feeding rollers 202 and an opening licker-in roller 203 in sequence between the wool feeding machine 1 and the No. 1 opening cylinder 204. The unit includes the No. 2 opening cylinder 210 and three pairs of working mechanisms composed of the working roller 209 and the depilling roller 208 arranged on the No. 2 opening cylinder 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com