Large-mode-field multilayer segmented cladding fiber

A large mode field and optical fiber technology, which is applied in clad optical fiber, multi-layer core/clad optical fiber, light guide, etc., can solve the problem of difficulty in making air holes in photonic crystal optical fiber, limited diameter of petal-shaped optical fiber core layer, large mode Solve the problems of low mass production yield of single-mode multi-core optical fiber in the field, and achieve the effect of improving single-mode transmission characteristics, reducing fiber loss, and realizing high-power single-mode laser output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

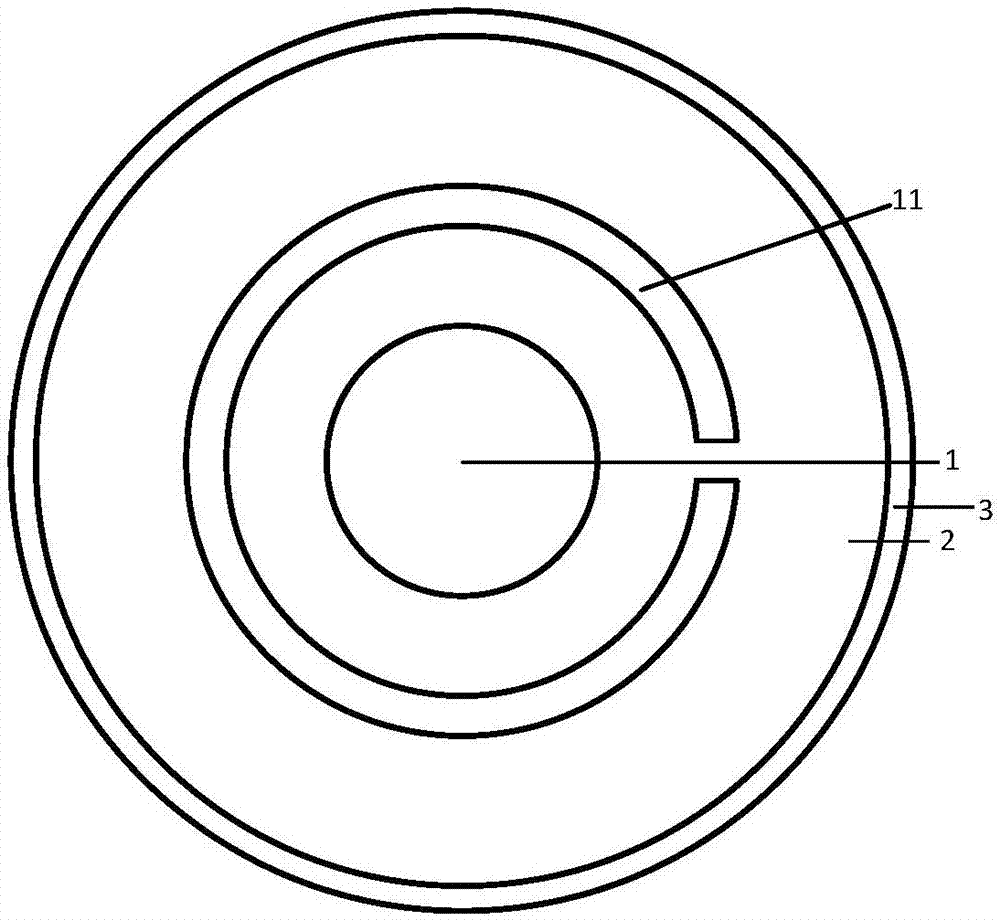

[0017] Large Mode Area 1 Suppression Channel 1 Layer Lobe Fiber, see figure 1 . The center of the optical fiber is a high-refractive-index fiber core (1), and outwards is an inner cladding (2). The inner cladding (2) contains a first high-refractive-index lobe (11), and the outermost layer is an outer cladding (3). In the example, M=1, N=1.

[0018] The refractive index of the high-refractive-index lobe (11) is equal to the refractive index of the high-refractive-index core (1); the refractive index of the high-refractive-index core (1) is greater than that of the inner cladding (2) and greater than that of the outer cladding (3) the refractive index.

[0019] The diameter of the high-refractive index core area (1) is 20 microns, the thickness of the high-refractive index lobe is 8 microns, the distance from the high-refractive index lobe to the fiber core is 10 microns, and the width of the suppression channel is 6 microns.

Embodiment 2

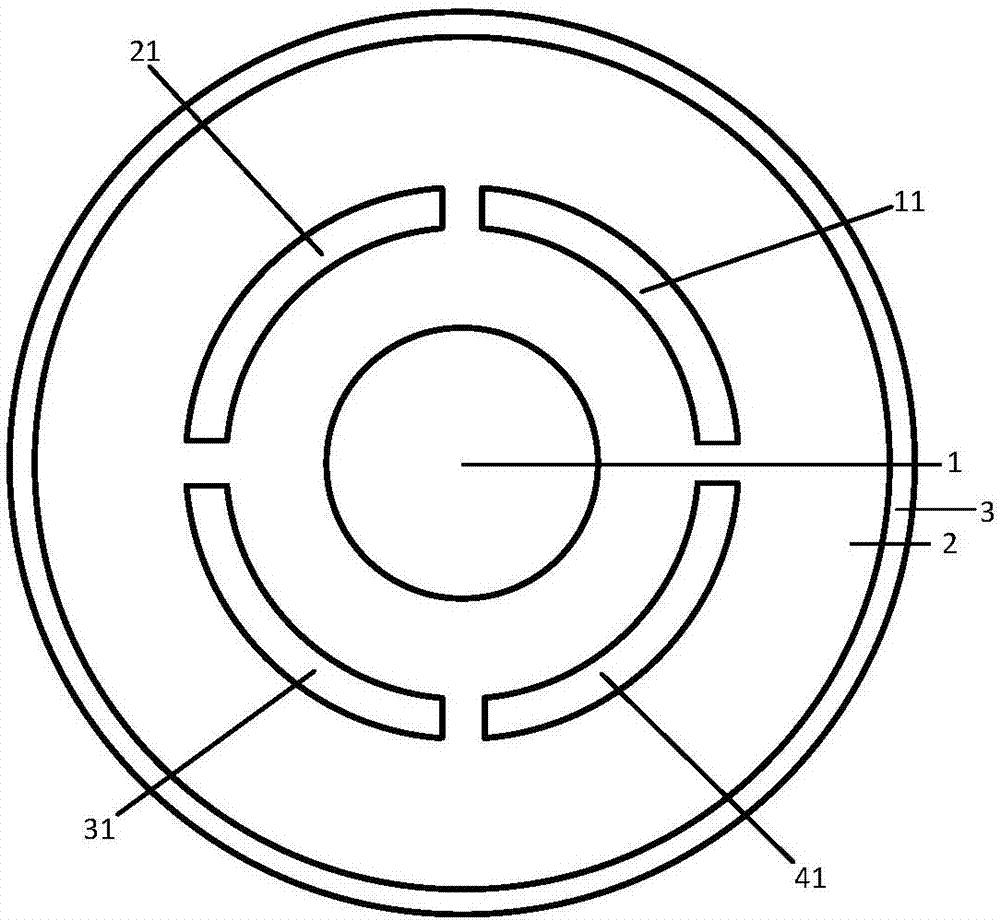

[0021] Large Mode Area 4 Suppression Channels 1 Layer Lobe Fiber, see figure 2 . The center of the optical fiber is a high-refractive-index core region (1), and outwards is an inner cladding (2). Layer (3), M=4, N=1 in this example.

[0022] The refractive index of the high-refractive-index lobes (11, 21, 31, 41) is equal to that of the high-refractive-index core (1), greater than that of the inner cladding (2), and greater than that of the outer cladding (3).

[0023] The diameter of the high-refractive index core area (1) is 20 microns, the thickness of the high-refractive index lobe is 8 microns, the distance from the high-refractive index lobe to the fiber core is 10 microns, and the width of the suppression channel is 6 microns.

Embodiment 3

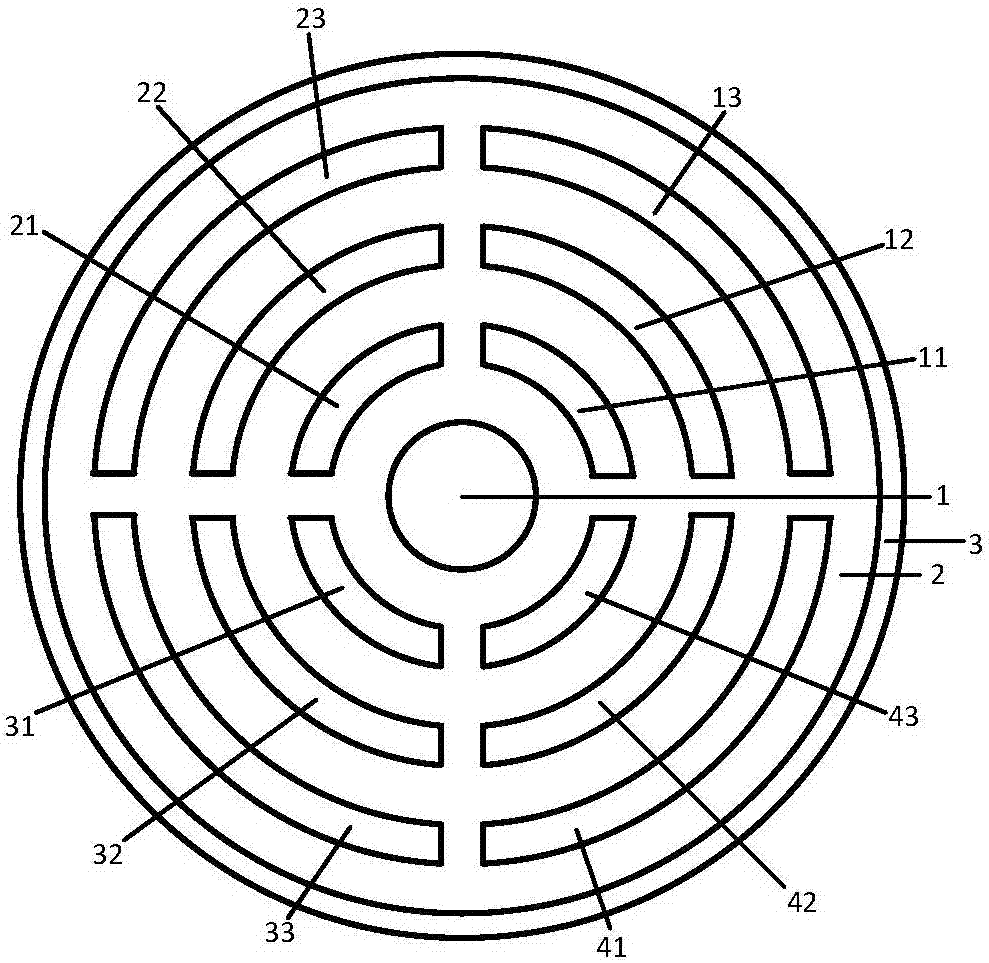

[0025] Large Mode Area 4 Suppression Channels 3-Layer Lobe Fiber, see image 3 . The center of the optical fiber is a high-refractive-index core region (1), and outwards is an inner cladding (2). The refractive index lobe (12, 22, 32, 42), the third layer of high refractive index lobe (13, 23, 33, 43), the outermost is the outer cladding (3), in this example M=4, N=3.

[0026] The refractive index of the high refractive index lobes (11, 21, 31, 41), (12, 22, 32, 42), (13, 23, 33, 43) is equal to the refractive index of the high refractive index core (1), greater than The refractive index of the inner cladding (2) is greater than that of the outer cladding (3).

[0027] The diameter of the high-refractive index core area (1) is 30 microns, the thickness of the high-refractive-index lobe is 8 microns, the distance between two adjacent high-refractive-index lobes is 10 microns, and the distance from the first high-refractive-index lobe to the fiber core is is 10 µm and the width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com