Electromagnetic diaphragm pump

A diaphragm pump, electromagnetic technology, applied in the direction of pumps, liquid displacement machinery, pumps with flexible working elements, etc., can solve the problems of pump performance degradation burrs, etc., to achieve the suppression of performance degradation, reliable isolation, and uniform thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments for carrying out the present invention will be described in detail with reference to the drawings.

[0034] In addition, this invention is not limited to the form demonstrated below, In the range which does not deviate from a technical idea, various deformation|transformation can be implemented. In addition, in the attached drawings, for the sake of explanation, the scales of up, down, and left and right are sometimes shown exaggeratedly, and may differ from actual scales.

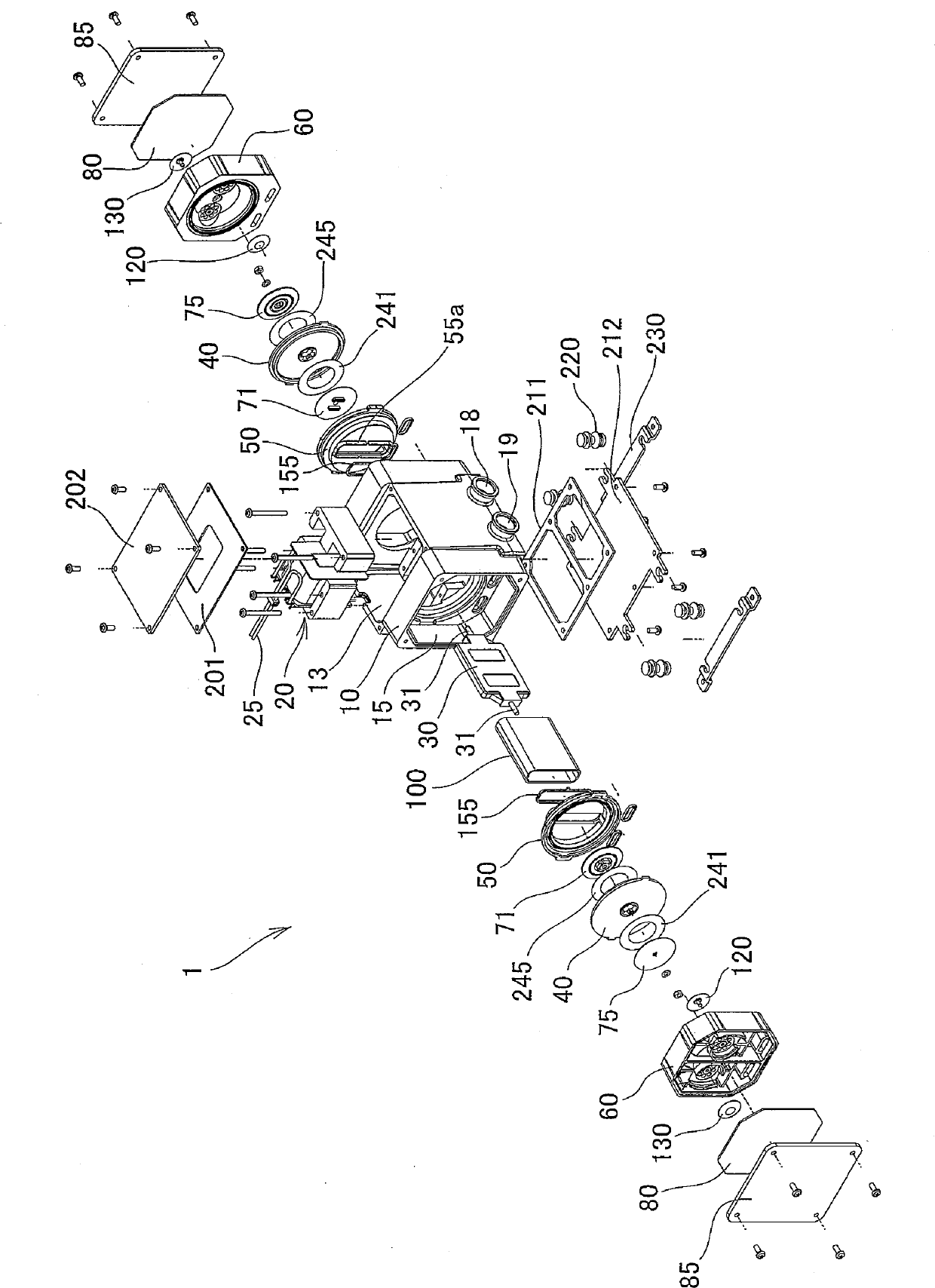

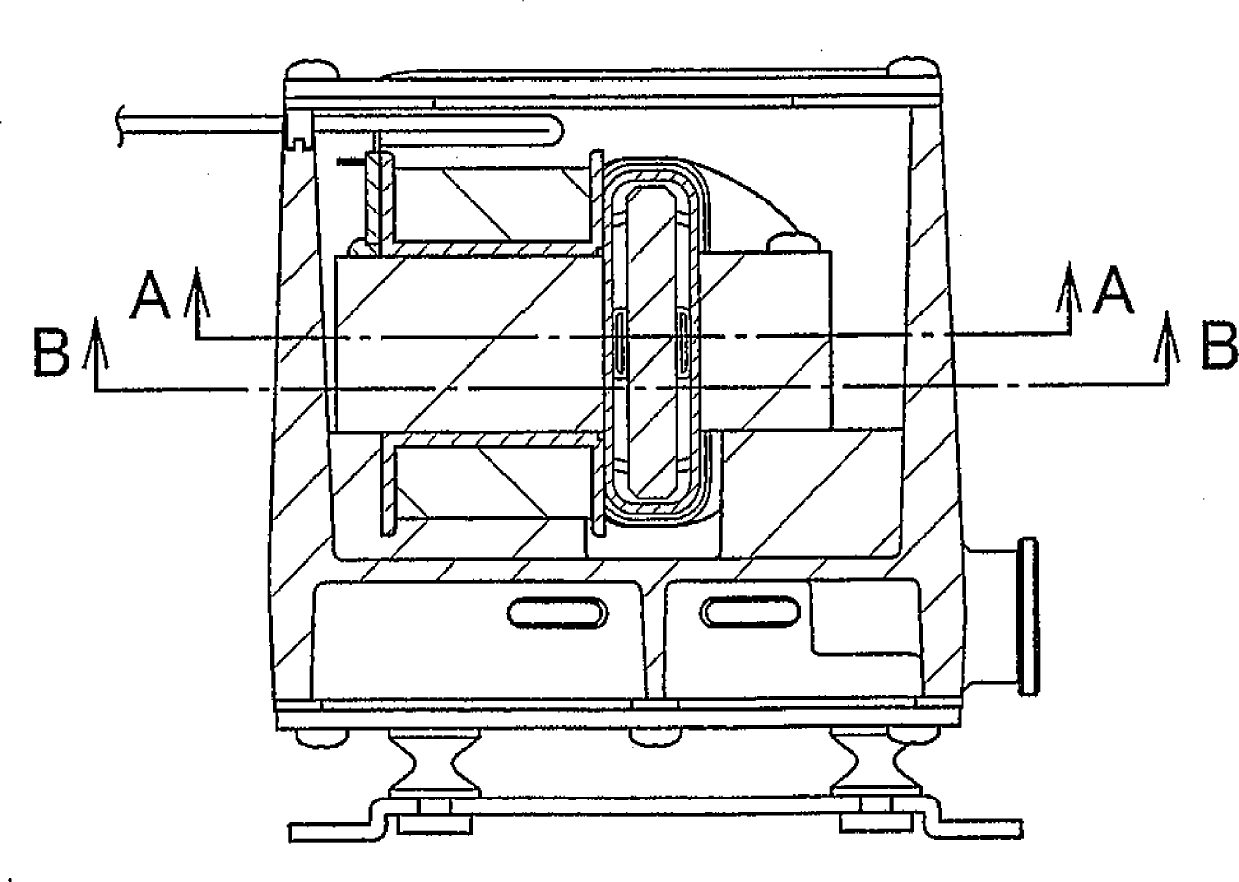

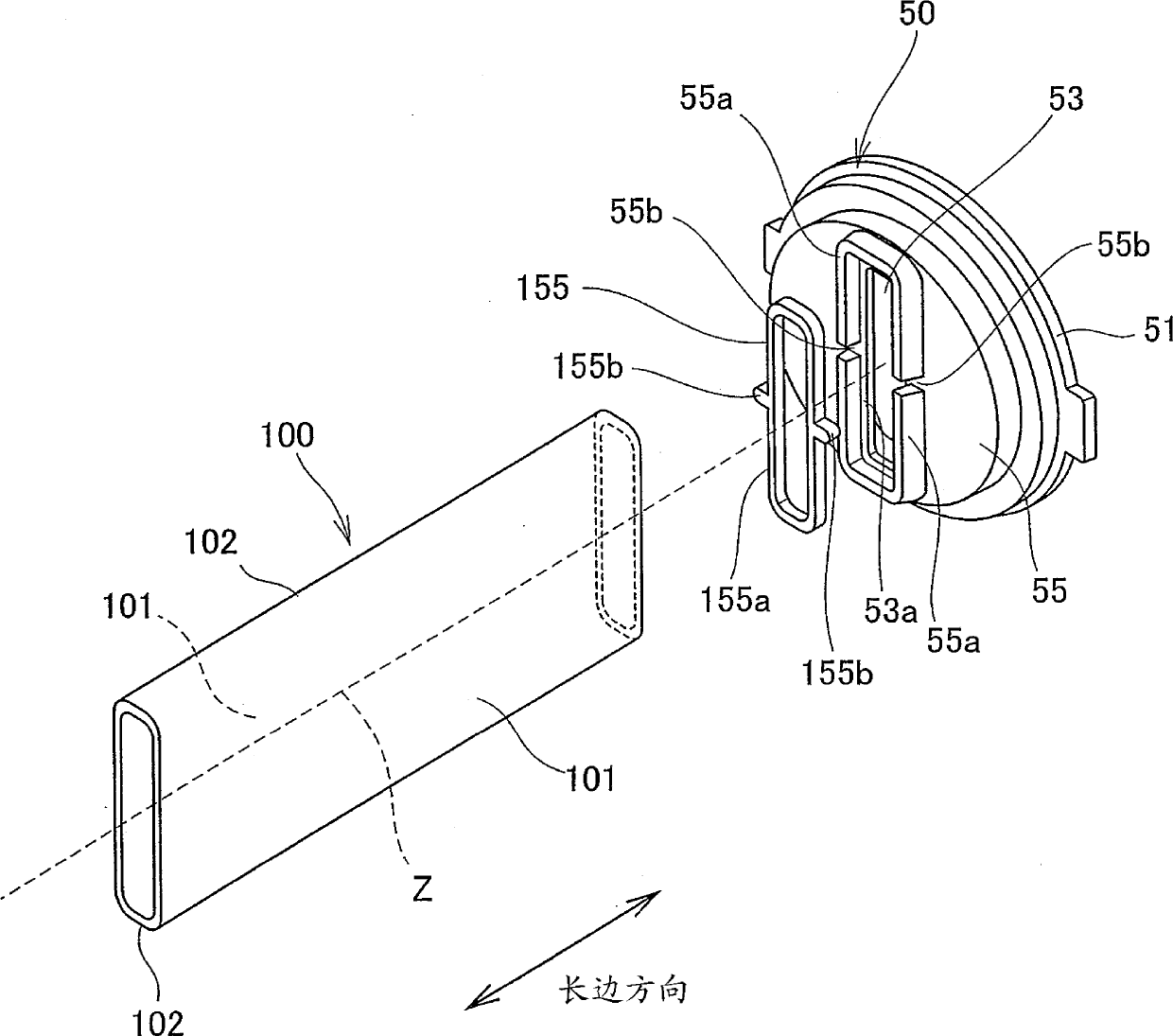

[0035] figure 1 It is a perspective view schematically showing the disassembled state of the electromagnetic diaphragm pump of the present invention into each main part, figure 2 It is a plan view showing the necessary parts of the main part of the electromagnetic diaphragm pump of the present invention in section, image 3 so figure 2 The section in the direction of the arrow II-II is a front view showing the essential parts of the main part of the electromagnetic diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com