Cross roller bearing and retainer thereof

A cross-roller and cage technology, applied in the field of cross-roller bearings and their cages, can solve the problems of inability to isolate, large vibration and noise of roller bearings, and low service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

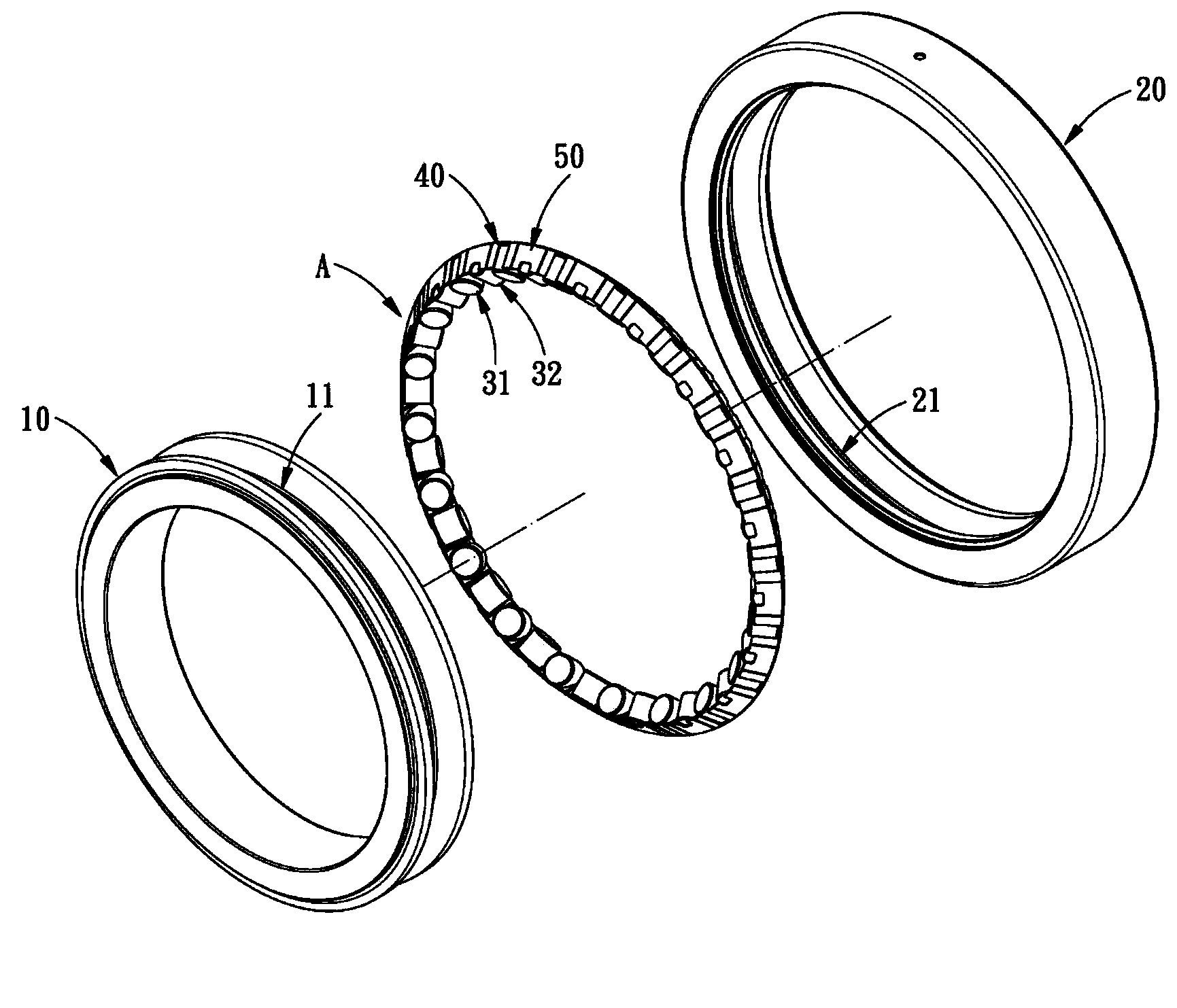

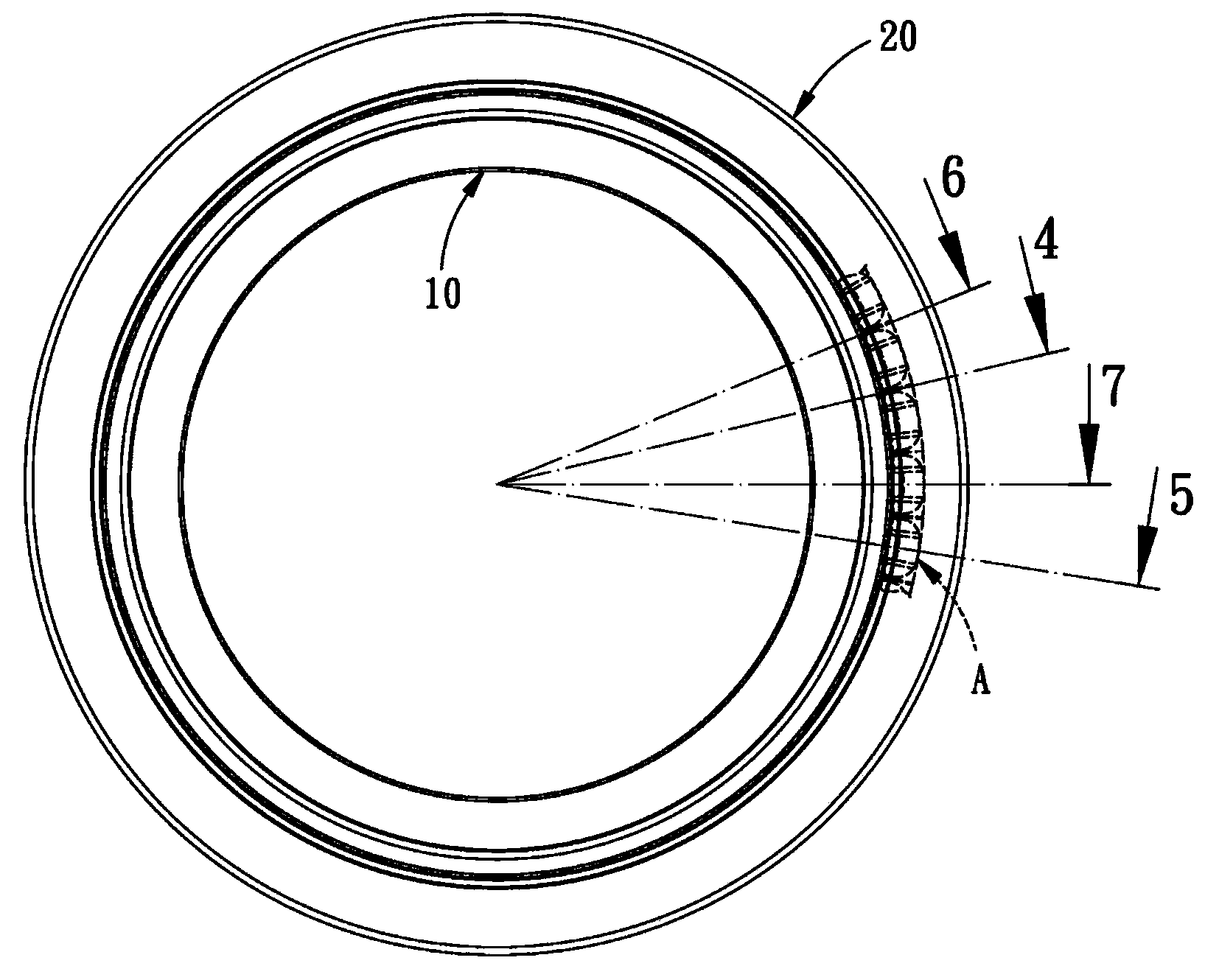

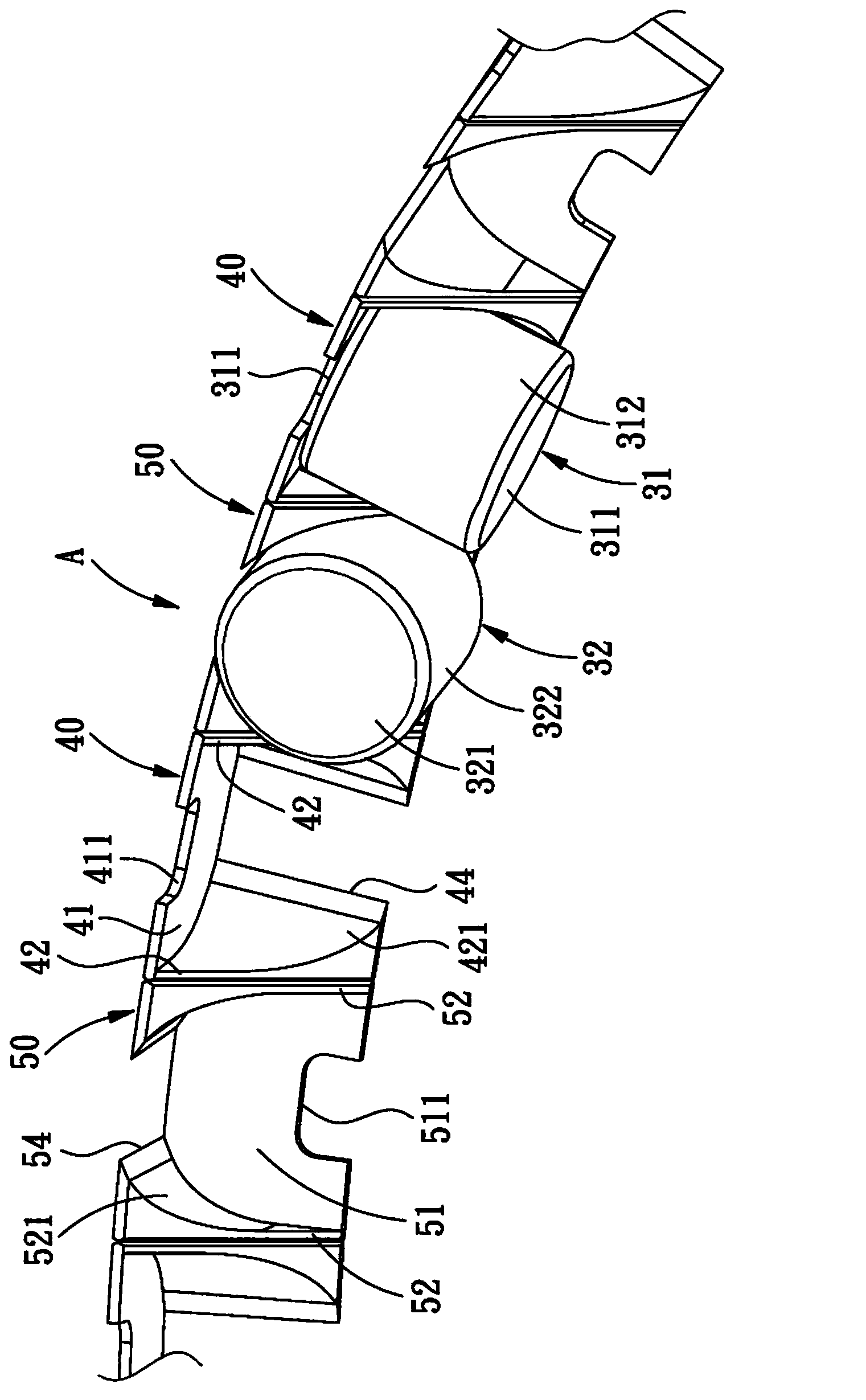

[0049] refer to Figures 1 to 4 As shown, the cage of a crossed roller bearing provided by the first embodiment of the present invention is suitable for assembly between the inner and outer rings 10, 20, and accommodates each roller 31, 32, and makes each Adjacent rollers 31, 32 are in a cross shape, the inner ring 10 has an inner rolling track 11 generally in the shape of a "﹤" groove, and the outer ring 20 has a pair of inner rolling tracks 11 that are generally in the shape of a ">" The outer rolling track 21 of the "shaped groove, so that the inner and outer rings 10, 20 form a rolling track for the cage A to assemble and a square section. The outer rolling track 21 includes a first outer track surface 211 and a The second outer raceway surface 212, and the angle between the first and second outer raceway surfaces 211, 212 is a right angle (90°), the rollers 31, 32 are cylindrical and have two circular end faces 311, 321 with equal diameters And the rolling surfaces 312, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com