Finned tube heat exchanger

A heat exchanger and finned tube technology, applied in the field of finned tube heat exchangers, can solve problems such as fin frosting, and achieve the effect of improving heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach )

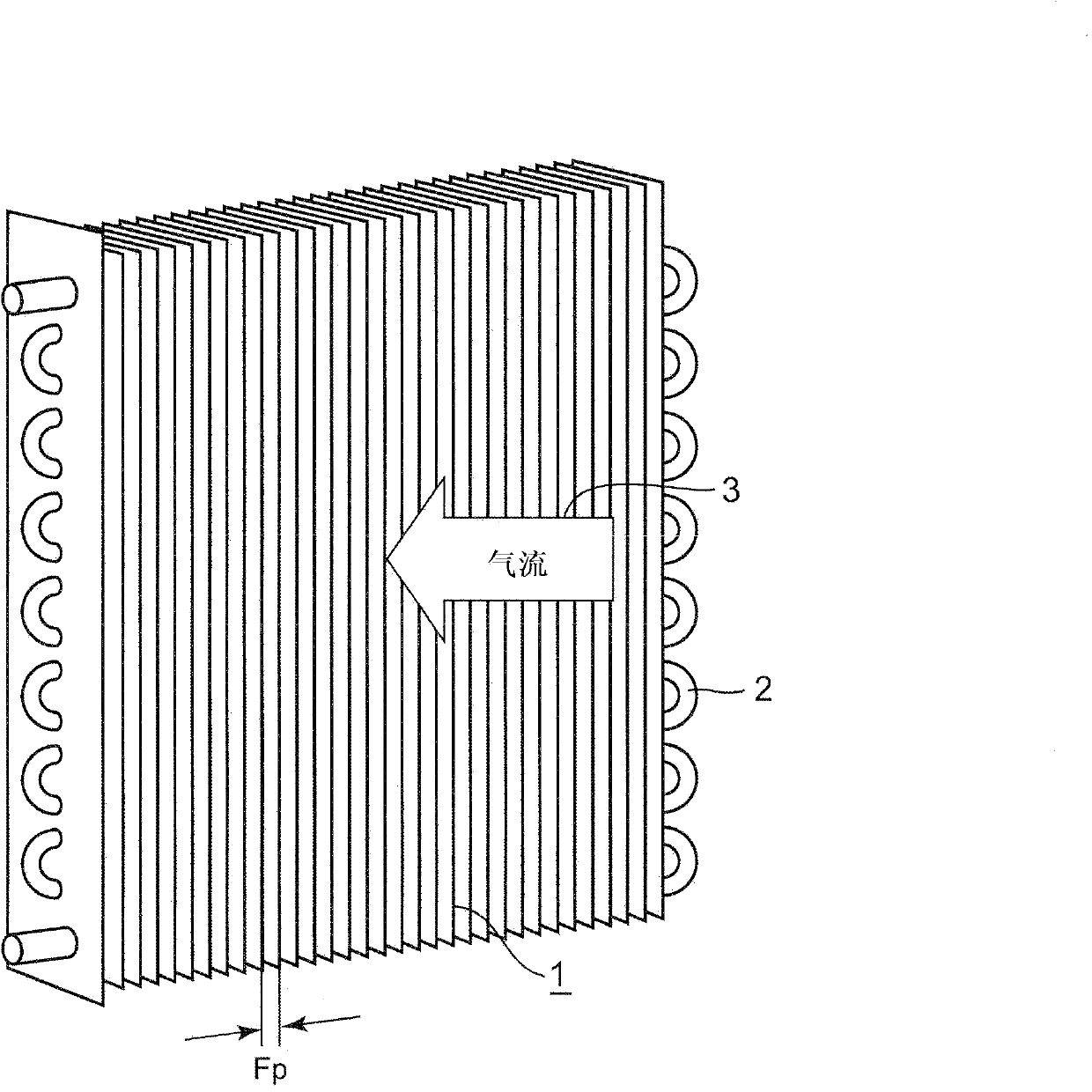

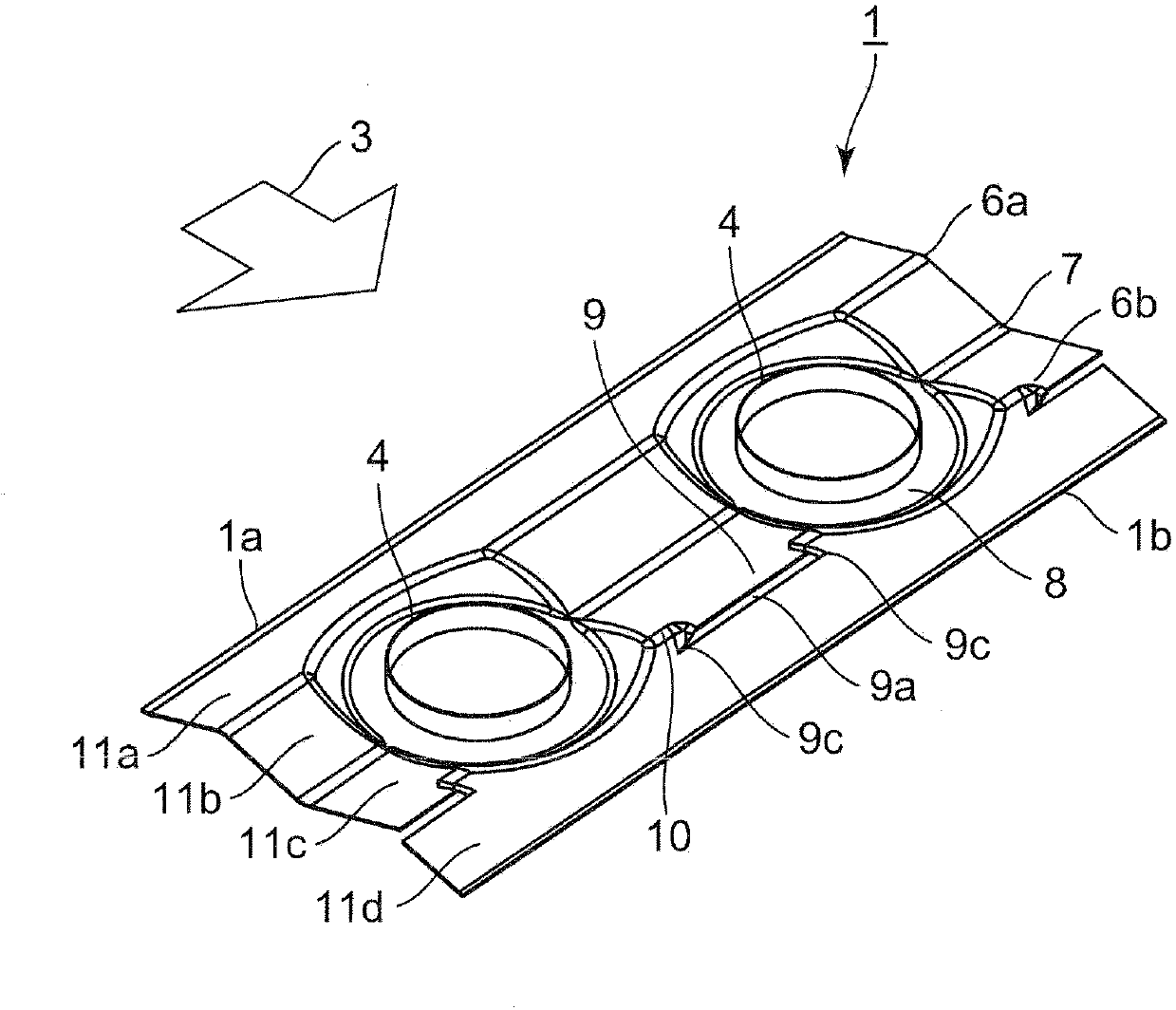

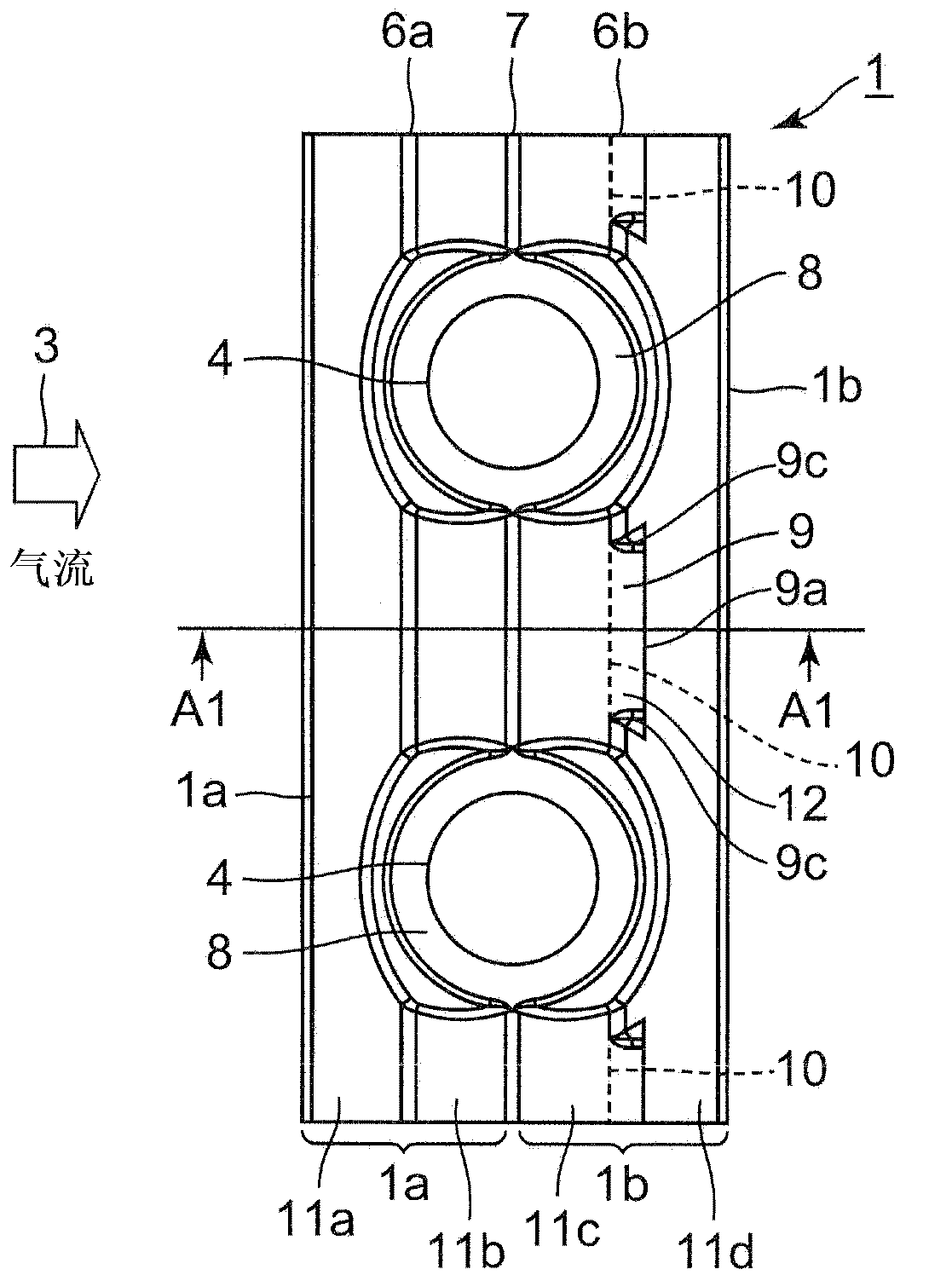

[0046] figure 1 It is a perspective view of the finned tube heat exchanger concerning embodiment of this invention. figure 2 yes figure 1 A partial perspective view of fins included in the shown finned tube heat exchanger. Figure 3A yes figure 2 A partial plan view of the fin shown. Figure 3B yes Figure 3A A1-A1 line sectional view. The finned tube heat exchanger according to the present embodiment is installed, for example, in outdoor units such as air conditioners, heat pump water heaters, and heat pump hot water heaters.

[0047] Such as figure 1 As shown, the finned tube heat exchanger of this embodiment includes: a plurality of fins 1 stacked at a distance Fp for forming the flow path of the airflow 3; Heat transfer tube 2.

[0048] Inside the heat transfer tube 2 , a fluid that exchanges heat with an air flow 3 such as air sent between the plurality of fins 1 by a blower (not shown) flows therethrough. Furthermore, if figure 1 As shown, a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com