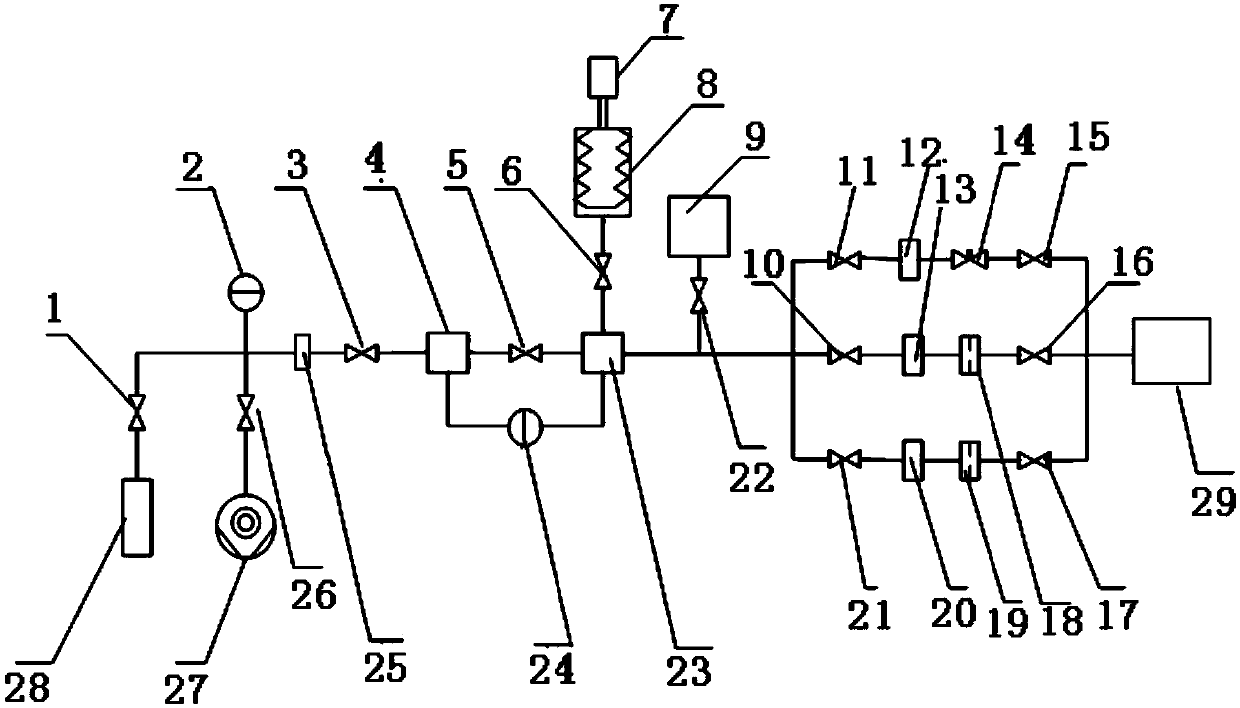

Multi-working-mode gas flowmeter and gas flow measuring method

A technology of gas flowmeter and working mode, which is applied in fixed measuring chambers and movable measuring chambers, can solve problems such as low baking temperature, large measurement uncertainty, and difficulty in extending the lower limit of gas flowmeter flow, and achieve The effect of expanding the measuring range and facilitating measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1: evacuate the gas flowmeter to a preset vacuum degree;

[0037] Step 2: Open the second cut-off valve, open the valve on the first branch, close the valve on the second branch, and fill the gas flow meter with gas;

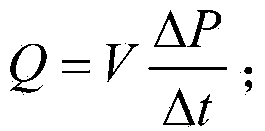

[0038] Step 3: After the air pressure in the reference chamber, comparison chamber and constant volume chamber in the gas flowmeter is stable, introduce the gas in the gas flowmeter into the calibration chamber, and then use the first pressure gauge to measure the preset time Compare the pressure change value in the inner chamber, and use the following formula to calculate the gas flow

[0039] Q = V ΔP Δt ; - - - ( 1 )

[0040] Wherein, Q is the gas flow rate; V is the total volume of the reference chamber, the comparison chamber, the constant volume chamber, the volume chamber on the fir...

Embodiment 2

[0044] Step 1: pumping the gas flowmeter to a preset vacuum degree, and heating and baking the gas flowmeter to a preset temperature during the pumping process;

[0045] Step 2: Open the second cut-off valve, close the valve on the first branch, open the valve on the second branch, and fill the gas flow meter with gas;

[0046] Step 3: After the air pressure in the reference chamber, the comparison chamber and the constant volume chamber in the gas flowmeter is stabilized, the gas in the gas flowmeter is introduced into the calibration chamber through a small-diameter connecting pipe, and the gas in the gas flowmeter is passed through the first pressure gauge. Measure the gas pressure in the gas flow meter, and use the following formula to calculate the gas flow at the small-diameter connecting pipe

[0047] Q'=cp; (2)

[0048] Among them, c is the flow conductance of the gas; p is the gas pressure in the gas flowmeter; Q' is the gas flow rate of the small-diameter connecting...

Embodiment 3

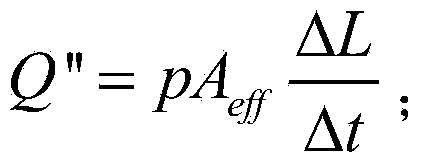

[0053] Step 1: pumping the gas flowmeter to a preset vacuum degree, and heating and baking the gas flowmeter to a preset temperature during the pumping process;

[0054] Step 2: Open the second cut-off valve, close the valve on the first branch, open the valve on the second branch, and fill the gas flow meter with gas;

[0055] Step 3: After the air pressure in the reference chamber, the comparison chamber and the variable capacity chamber in the multi-working mode gas flowmeter is stable, introduce the gas in the multi-working mode gas flowmeter into the calibration chamber through a small-caliber connecting pipe , close the third shut-off valve and then stop filling gas into the multi-working mode gas flow meter, measure the pressure difference between the reference chamber and the comparison chamber through the differential pressure manometer, and open the first cut-off valve The valve introduces the gas in the comparison chamber into the variable volume chamber, and drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com