Electrical equipment SF6 gas leak detecting device and SF6 gas collecting method

A kind of electrical equipment, SF6 technology, applied in the field of SF6 gas leak detection device of combined electrical appliances, can solve the problems of unsafety, low accuracy rate, increased physical strength of personnel, etc., and achieve accurate gas guidance, easy processing and production, and highly targeted collection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

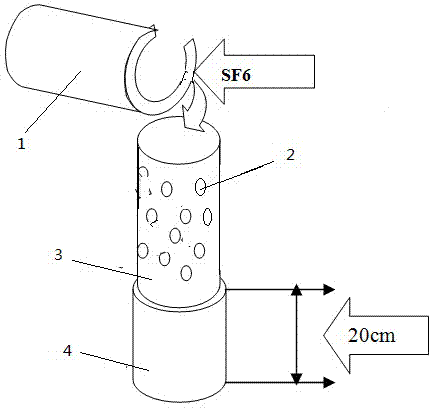

[0015] Examples: figure 1 As shown, the electrical equipment SF of the present invention 6 The manufacturing steps of the gas leak detection device are:

[0016] 1. Take a PVC pipe with a diameter of 10cm and take a point on the wall of one end of the PVC pipe. Take this point as the center and the angle of the center is 30 degrees. The fan shape is formed on the wall of the PVC pipe. The arc, respectively cut from the two points of the arc along the length of the PVC pipe to form a notch groove, which is the gas collecting groove 1 of the present invention;

[0017] 2. Place the PVC pipe flat beside the combined electrical appliances of the power system, and the notch groove of the PVC pipe is upward; set a vertical diversion pipe 3 under one end of the PVC pipe, and the gap between the PVC pipe and the diversion pipe is 105 Diversion holes 2 are evenly distributed on the diversion tube 3;

[0018] 3. Set SF under the draft tube 3 6 Gas collecting barrel 4;

[0019] 4. SF 6 Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com