Automatic glue cover penetrating machine

A rubber shell machine and automatic threading technology, applied in the field of rubber shell threading, can solve the problems of high cost, low efficiency, increased operator burden, etc., and achieve the effect of improving efficiency, reducing cost and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

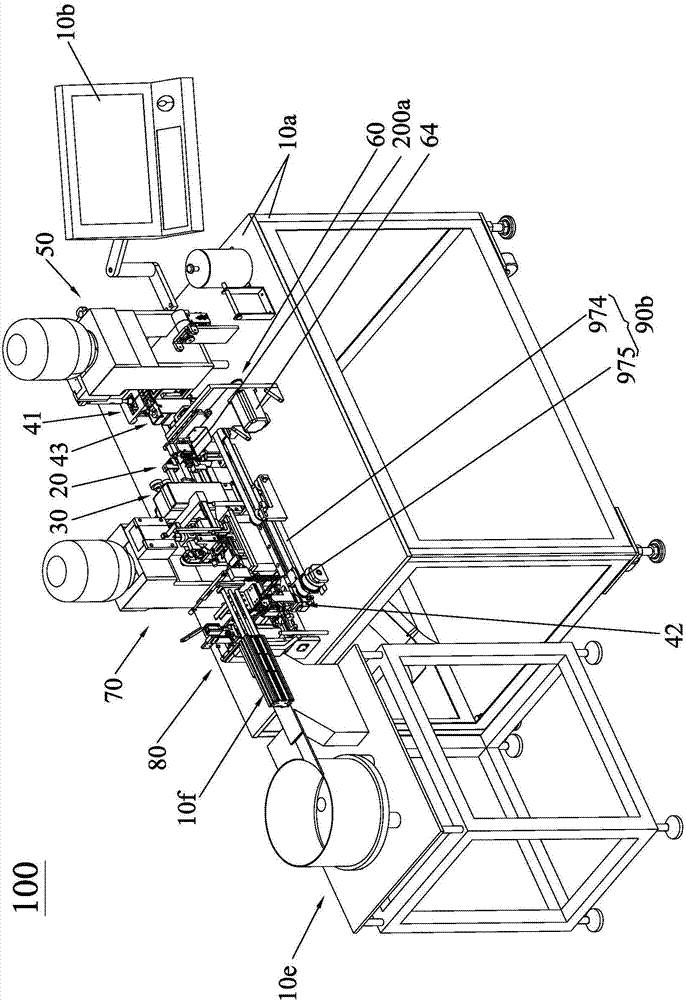

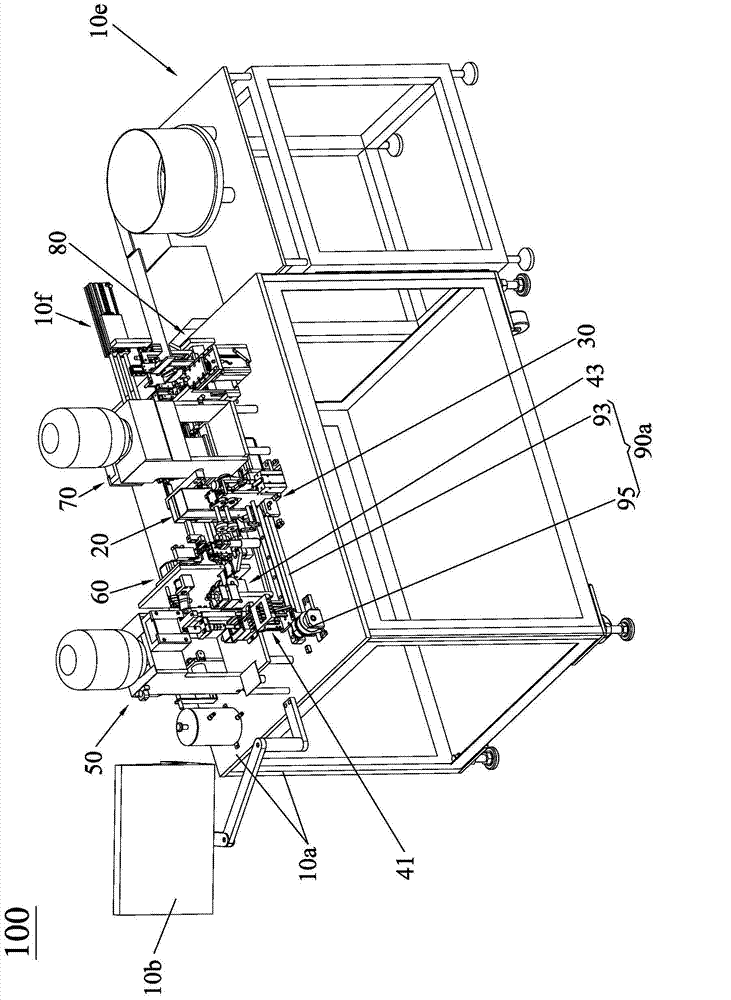

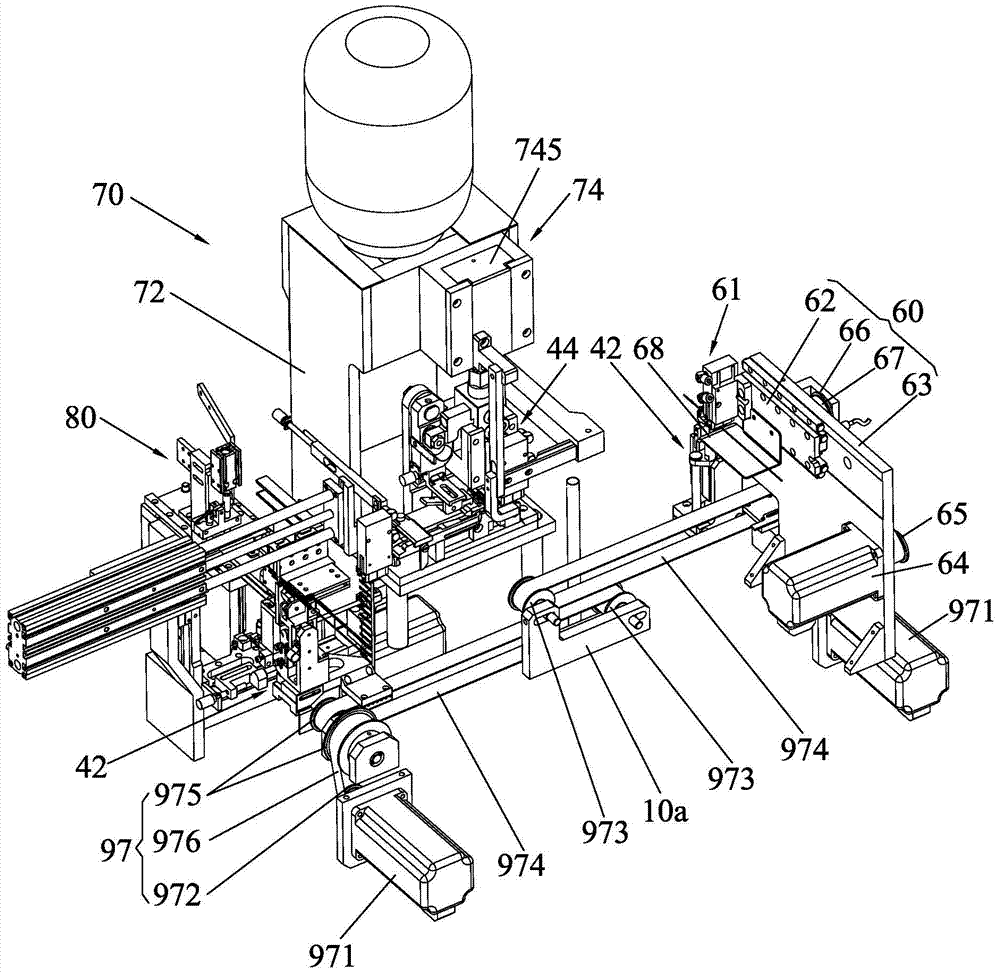

[0029] see figure 1 and figure 2 , the automatic rubber casing machine 100 of the present invention includes a frame 10a, a controller 10b disposed on the frame 10a, a cutter mechanism 20 electrically connected to the controller 10b, a wire feeding mechanism 30, a first wire clamp 41, The second wire clip 42, the flux dipping mechanism 43, the tin dipping mechanism 50, the wire pulling mechanism 60, the terminal punching mechanism 70, the plastic shell threading mechanism 80, the first wire clip driving mechanism 90a and the second wire clip driving mechanism 90b. Wire 200 (see Figure 13 , Figure 15 , Figure 17a or Figure 17b ) horizontally threaded on the first wire clamp 41, specifically, the length direction of the wire 200 is arranged along the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com