Drill Body for Indexable Drills

A drill and main body technology, applied in the field of indexable drills, can solve the problems of reduced durability, increased cutting resistance, restricted processing conditions, etc., and achieves the effects of high rigidity, high chip discharge performance, and improved chip discharge performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

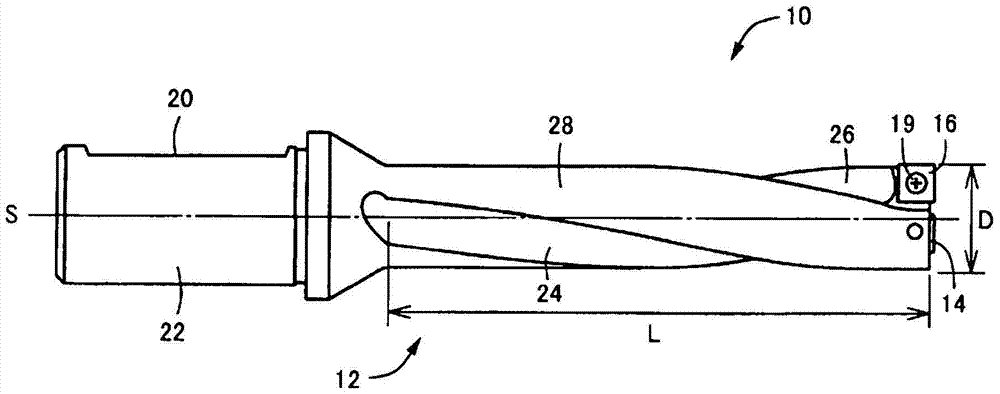

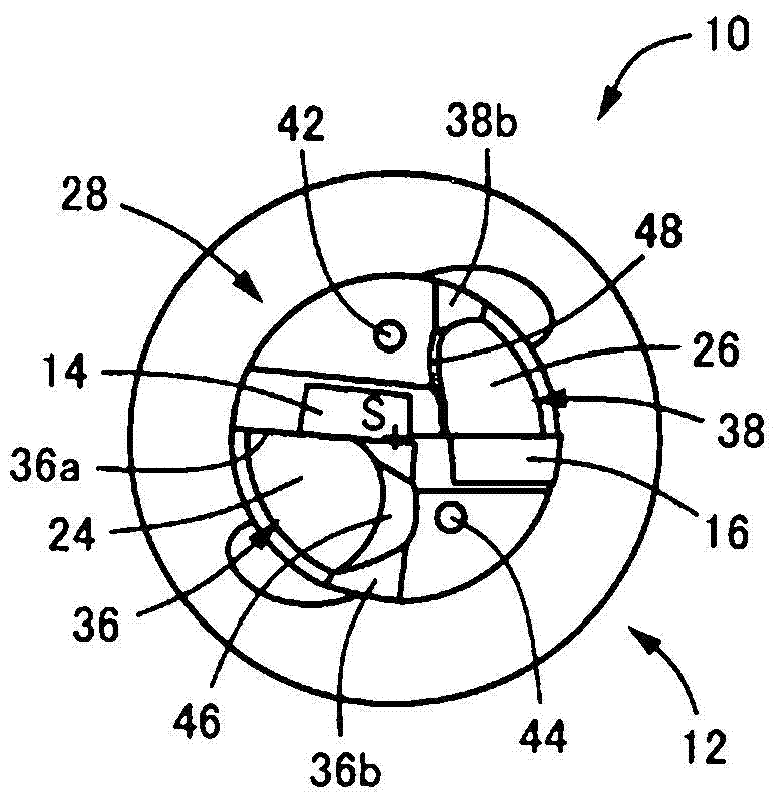

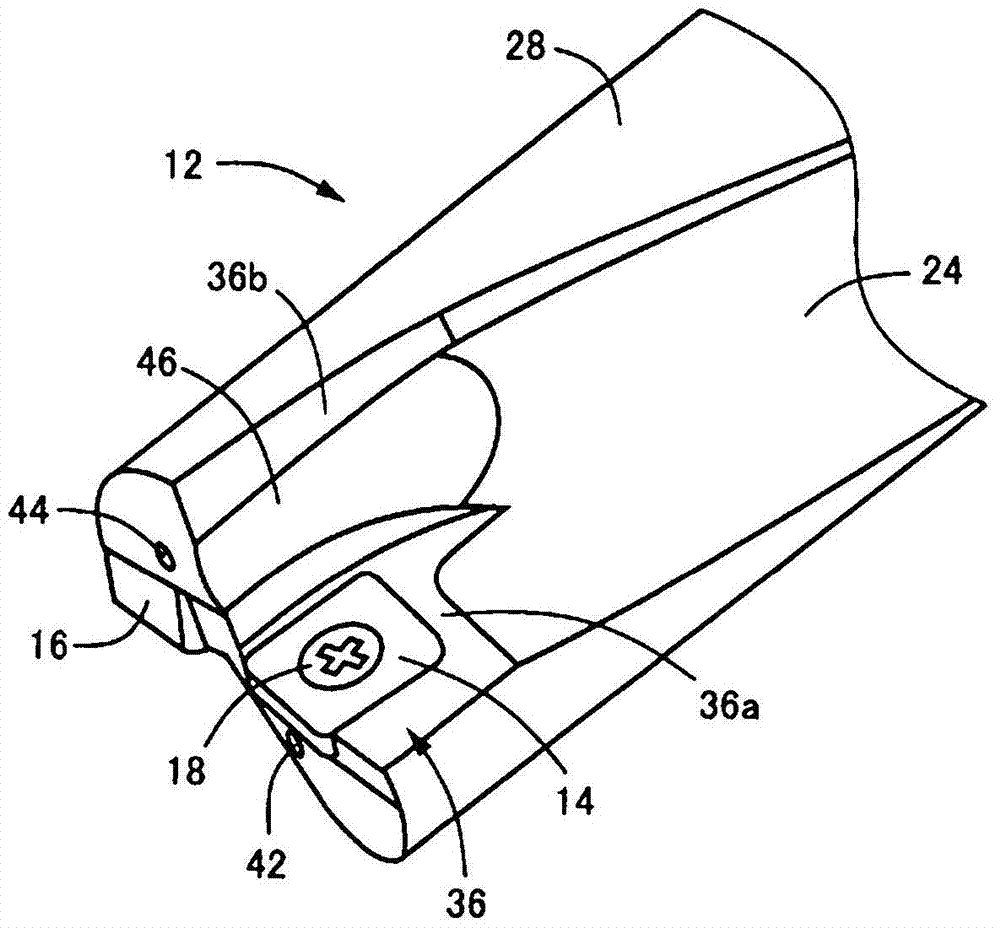

[0035] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0036] figure 1 It is a top view of an indexable drill 10 according to an embodiment of the present invention viewed from a direction perpendicular to the axis S, figure 2 is from the front side ( figure 1 The right side of ) observes and magnifies the magnified bottom view shown, image 3 It is a perspective view enlargedly showing a front end part. The indexable drill 10 is used by integrally detachably attaching a pair of inner inserts 14 and outer inserts 16 to the front end portion of a cylindrical drill body 12 via attachment screws 18 , 19 . The inner insert 14 cuts the center of the hole and is attached near the axis S of the drill body 12 , and the outer insert 16 cuts the outer periphery of the hole and is attached to the outer periphery of the drill body 12 . These inner blades 14 and outer blades 16 are formed into a square flat plate shape by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com