Electrified fastening antivibrator bolt insulation torsion wrench

A technology of torque wrench and anti-vibration device, which is applied in the field of torque wrench, can solve problems such as high risk, shutdown, and power failure of power users, and achieve the effects of improving safety, reducing resistance, and shortening working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

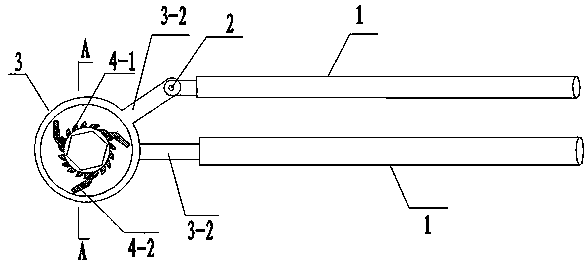

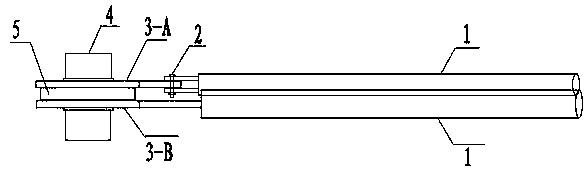

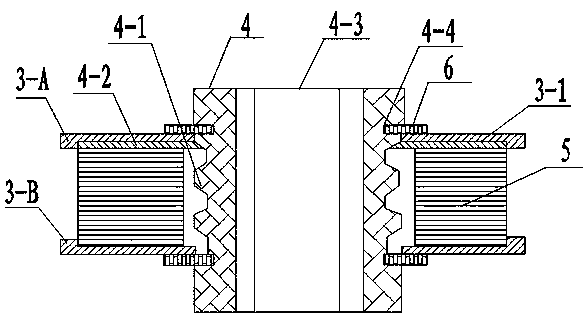

[0017] An insulated torque wrench for fastening anti-vibration bolts with electricity, including a sleeve 4, the inner hole of which is an inner hexagonal cavity 4-3 that matches the nut of the anti-vibration bolt, and the outer middle of the sleeve 4 is There is a ratchet 4-1 on the surface, the diameter of the ratchet 4-1 is consistent with the outer diameter of the casing 4, and the outer surface of the ratchet 4-1 is fixedly sleeved with a ring-shaped insulating washer 5, and the thickness of the insulating washer 5 is the same as that of the teeth of the ratchet 4-1. The thickness in the vertical direction is consistent, and the two sides of the insulating washer 5 are respectively equipped with an insulating disk 3 with a handle 3-2, and the insulating disk 3 is movably connected with the insulating washer 5 and the casing 4. The insulating disk 3 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com