A screw-type round bottle automatic feeding machine

A technology of screw type and bottle holder, which is applied in the direction of automatic packaging control, packaging bottles, packaging, etc., can solve the problems of excessive material conveying height drop, stagnation of the whole line, pressure loss, etc., and achieve large buffer capacity and high accuracy of feeding , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

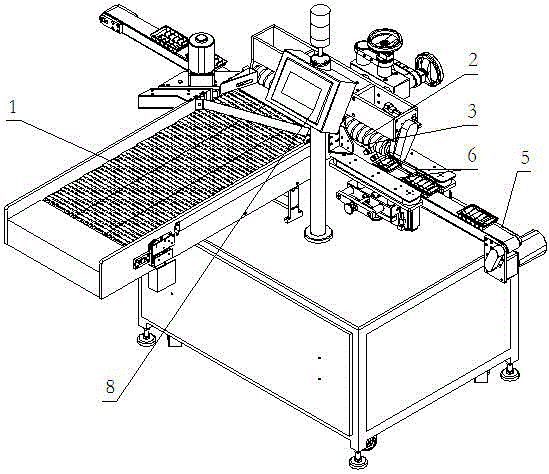

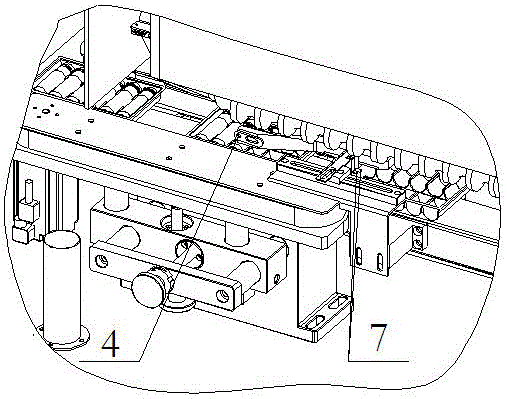

[0012] The structure diagram of the present invention is as figure 1 , 2 As shown, the screw-type round bottle automatic loading machine of the present invention includes a vertical bottle supply conveying platform 1, a servo screw 2, a vertical turning horizontal track 3, a bottle measuring sensor 4, a bottle carrier conveyor belt 5, and a servo bottle carrier entrainment belt 6 , bottle holder detection and positioning sensor group 7, electric control system 8, wherein the vertical bottle supply conveying platform 1 supplies the bottle to the servo screw 2 in a standing position; the servo screw 2 is driven and rotated by the motor to separate the bottles into each bottle and send it to the bottle release position The bottle is controlled in the thread groove, and the bottle is gradually turned into a lying position in the vertical turning and lying track 3. The exit of the vertical turning and lying track 3 is equipped with a bottle measuring sensor 4 to detect whether ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com