Unit-type outwards-lifted glass rib hooking system

A technology of glass ribs and units, which is applied in the direction of building components, walls, buildings, etc., can solve problems such as the inability to realize the unit installation of glass ribs and the inability to meet the structural stability requirements of large-sized glass ribs, and achieve simple structure and The effect of high stability and balanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

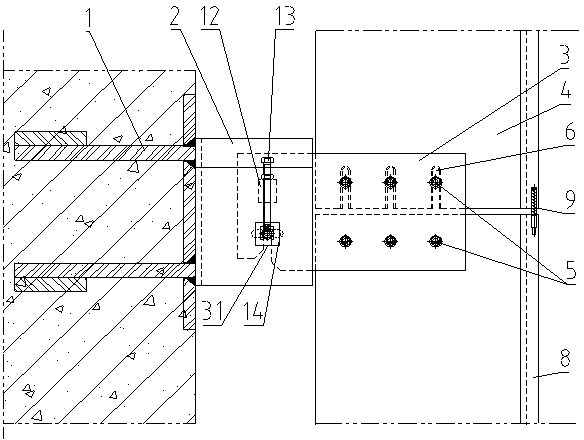

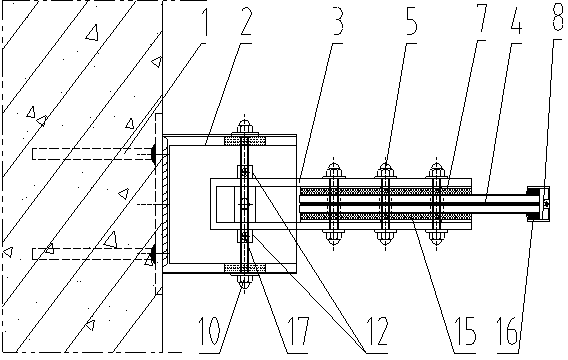

[0029] figure 1 , figure 2 It is a unitized hanging glass rib hanging system of the present invention, which is used for hanging the glass rib decorative strips arranged longitudinally on the surface of the glass rib. It includes an embedded part 1 embedded in the wall, a suspension connecting part 2 fixedly connected to the embedded part 1, and a glass rib connecting part 3 detachably connected to the hanging connecting part 2. The part of the glass rib connecting piece 3 protruding from the outside of the suspension connecting piece 2 has clamping surfaces parallel to each other, and the ends of two adjacent glass ribs 4 are inserted into the clamping surfaces of the glass rib connecting piece 3 and respectively The connection is via a first fastener 5 .

[0030] The above is the core solution of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com