Three-layer separate injection string and three-layer separate injection method for oil well

A technology of pipe injection and oil pipe, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of complex procedures, complex structure, and failure of pipe strings of eccentric water distributors, so as to achieve fast and convenient water distribution and improve the efficiency of water distribution. Anti-blocking ability, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

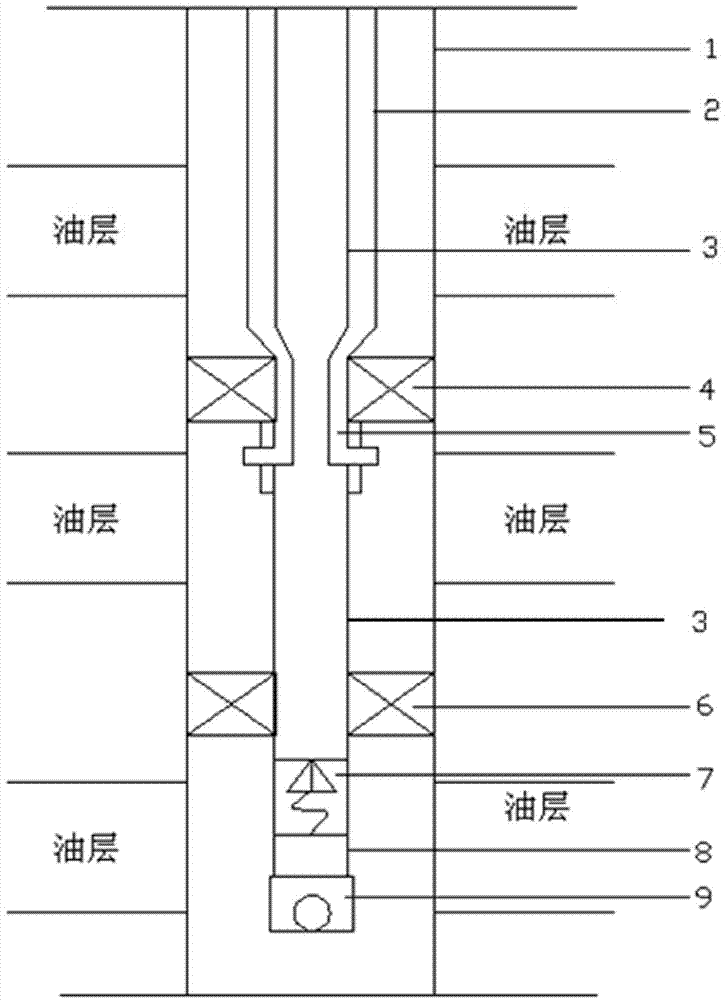

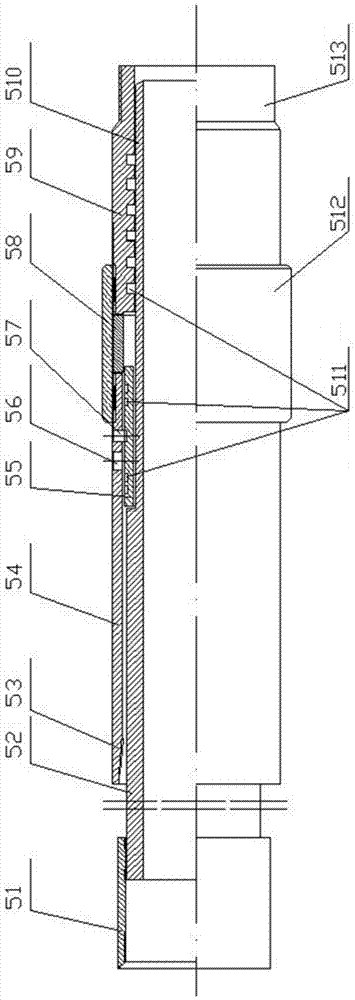

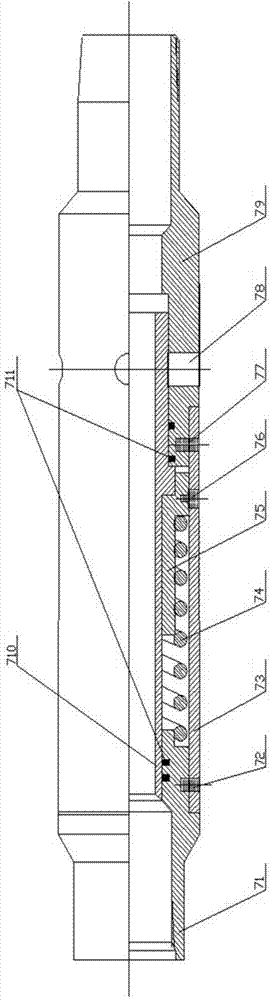

[0040] A three-layer separate injection string and a three-layer separate injection method for an oil well of the present invention comprise an outer pipe combination and an inner pipe combination; device, small size tubing, second expandable packer, constant pressure switch and ball seat, and are fixedly connected in sequence from top to bottom; the inner tube combination includes: small size tubing and shunt insertion pipe; the shunt insertion pipe It can correspond to the sliding sleeve inside the diverter water distributor, and there is a gap between its non-insertion section and the cylinder body of the diverter water distributor; the pipe string is lowered into a designated position in the bushing, A steel ball is placed on the ball seat; the setting pressure of the first expandable packer and the second expandable packer is lower than the shear pressure of the shear pin of the constant pressure switch. The invention has simple structure and convenient operation, not onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com