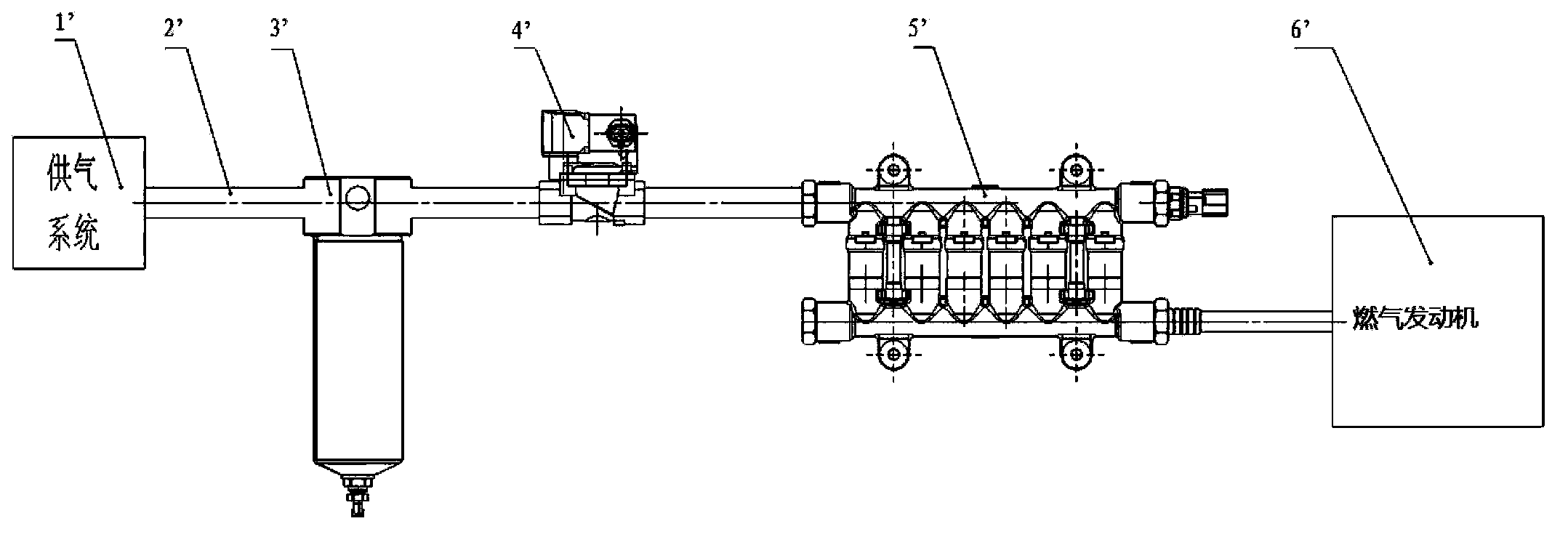

Gas engine air supply pipe interlocking valve mechanism

A gas engine and gas supply pipeline technology, applied to combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of not having the function of manually closing the gas supply pipeline, potential safety hazards, and inability to discharge, so as to shorten the emergency response time , The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

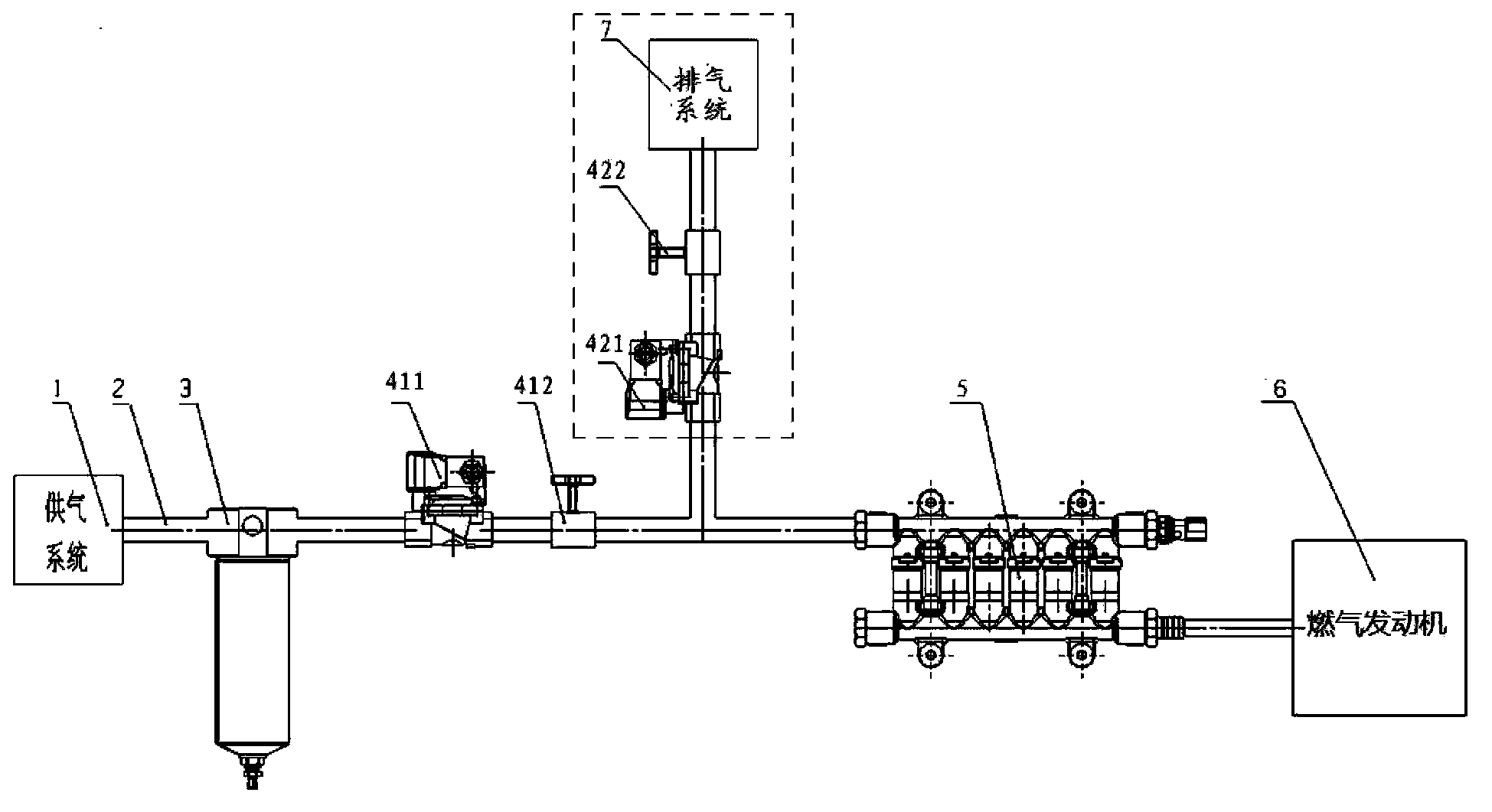

[0022] Such as figure 2 As shown, the gas engine air supply pipeline interlock valve mechanism in Embodiment 1 includes a first solenoid valve 411 and a second solenoid valve 421 controlled by the electronic control unit ECU, and a manually controllable first manual valve 412 and a second manual valve. Valve 422. The first solenoid valve 411 is arranged on the gas supply pipeline 2 between the gas filter 3 and the gas injection system 5 ; the first manual valve 412 is connected in series to the rear end pipeline of the first solenoid valve 411 . One end of the gas injection system 5 communicates with the rear end pipeline of the first manual valve 412 , and the other end of the gas injection system 5 communicates with the gas engine 6 . Exhaust lines (such as figure 2 The dotted line frame part) communicates with the pipeline between the first manual valve 412 and the gas injection system 5 . The exhaust pipeline is provided with a second solenoid valve 421 , a second man...

Embodiment 2

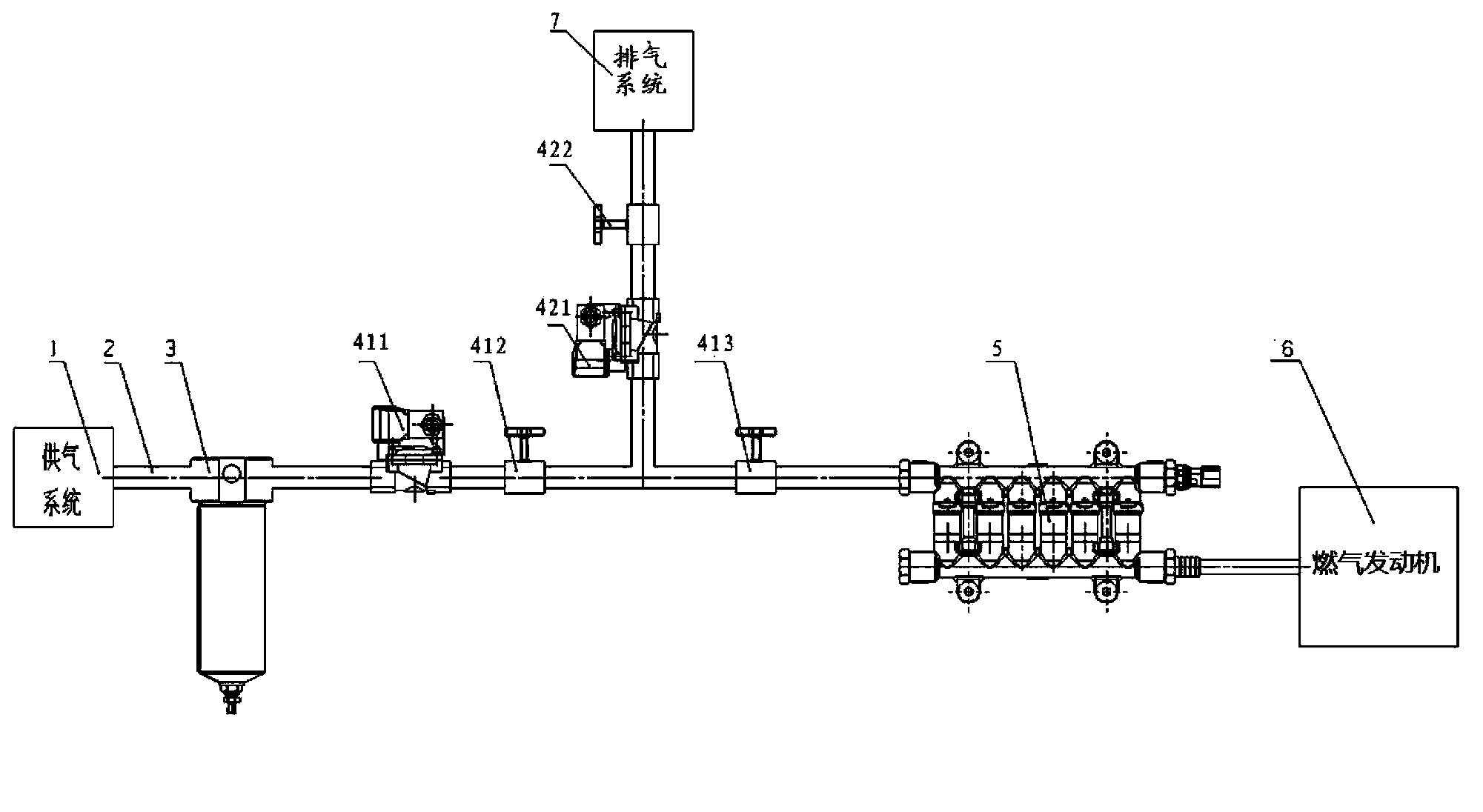

[0028] In practice, the air supply line of the engine is sometimes relatively long. In Embodiment 1, if the staff finds that the electromagnetic valve is faulty, it will take a long time to go to the vicinity of the gas supply system to manually close the first manual valve 412 near the engine. Therefore, a more preferred embodiment 2 is further proposed on the basis of embodiment 1. Such as image 3 As shown, the gas engine air supply pipeline interlock valve mechanism in Embodiment 2 includes a first solenoid valve 411 and a second solenoid valve 421 controlled by the electronic control unit ECU, and a manually controllable first manual valve 412 and a second manual valve. Moving valve 422 and the third manual valve 413. The first solenoid valve 411 is set on the gas supply pipeline 2 between the gas filter 3 and the gas injection system 5; the first manual valve 412 and the third manual valve 413 are sequentially connected to the rear end pipe of the first solenoid valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com