Method for measuring austenite content in steel by using X-ray diffraction technology

A technology of austenite content and technology measurement, which is applied in the field of X-ray diffraction test, can solve the problems of cumulative intensity ratio exceeding and not mentioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for measuring austenite content in steel using X-ray diffraction technology, including the following specific steps:

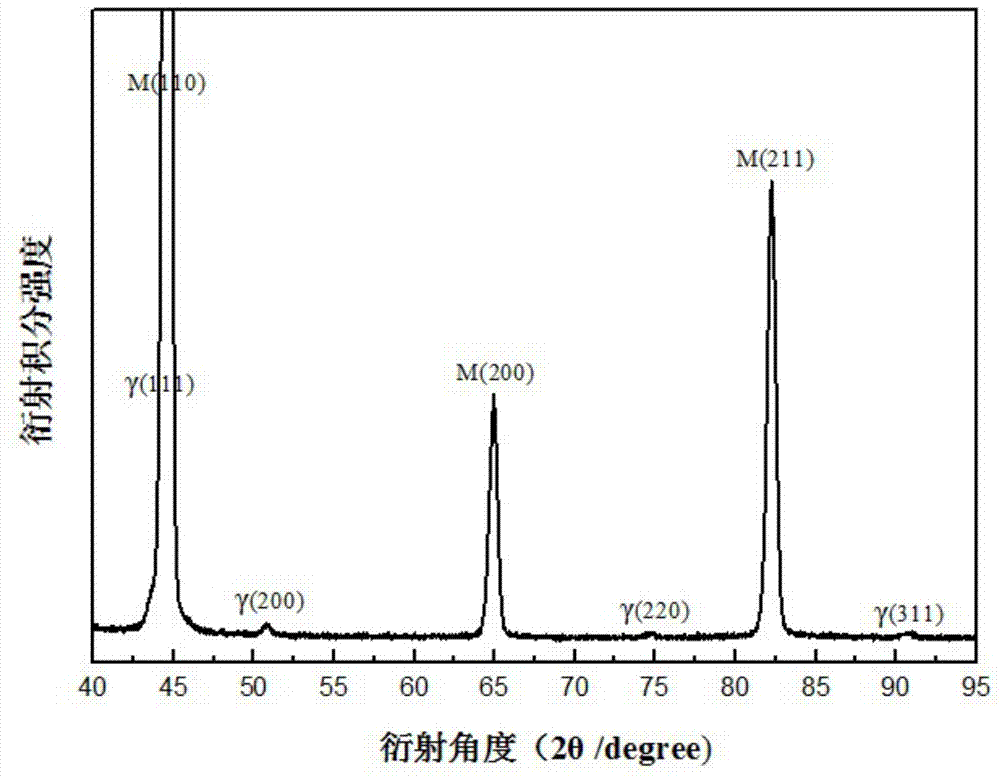

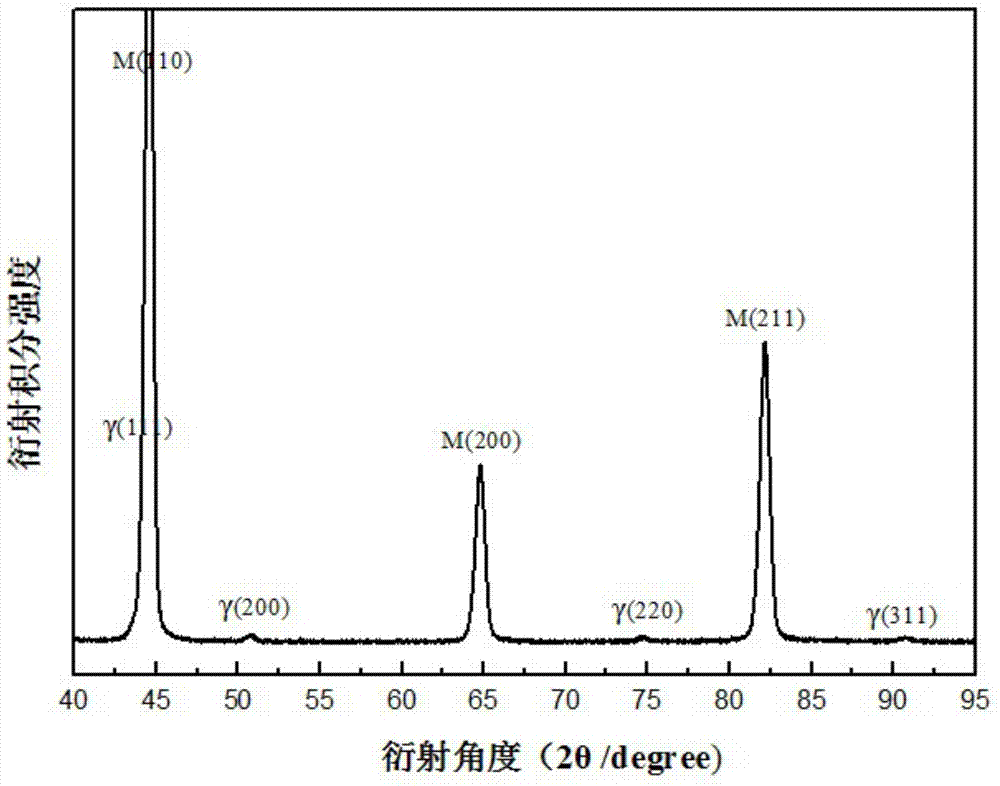

[0034] Step (1): Use an X-ray diffractometer to scan the steel sample to obtain the XRD pattern of the steel sample. The scanning speed is less than or equal to 1° / min to improve the signal-to-noise ratio and obtain a high-quality XRD pattern;

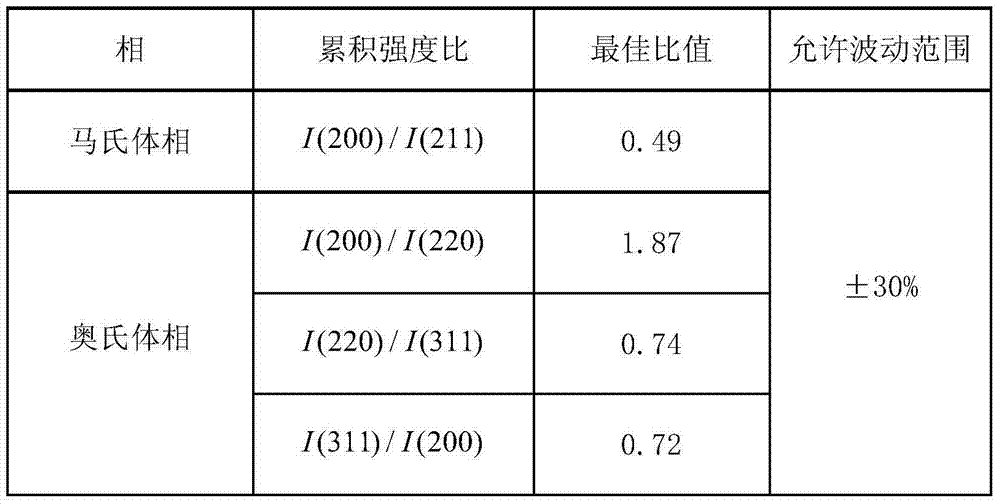

[0035] Step (2): Use the XRD spectrum in step (1) and the following formula to calculate the relative diffraction intensity when each crystal plane of martensite and austenite has no preferred orientation:

[0036] I = M · L P · F 2 · e - 2 M · A * ( θ ) - - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com