Generative fining characterization method for part key technology surface

A refined characterization and refinement technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of deviation from the actual situation, manufacturing process errors, inaccurate computer-aided engineering analysis, etc., and achieve low-cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

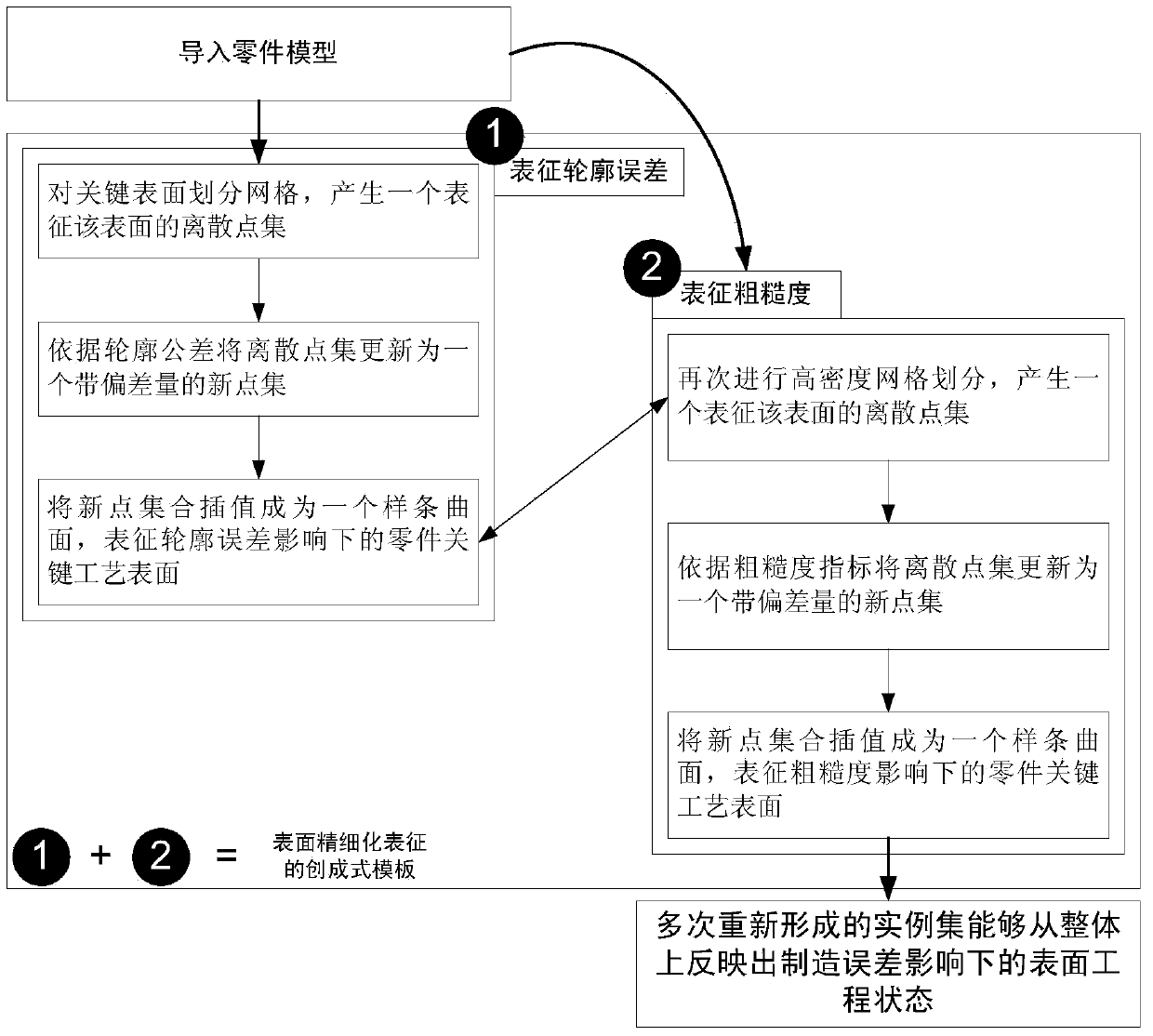

[0031] refer to figure 1 , a generative fine-grained characterization method for the key process surface of a part, embodied as a functional plug-in developed based on VBScript script language and embedded in the 3D CAD software CATIAV5R21, its main functions are described as follows: It will be used for fine-grained surface modeling of precision parts Modeling and reconstruction methods are computerized to create a generative template for automated surface refinement operations. According to the engineering parameters input by the user, aiming at the nominal model of precision parts, the corresponding surface refinement expression instance with manufacturing error features is generated. Specifically include the following steps:

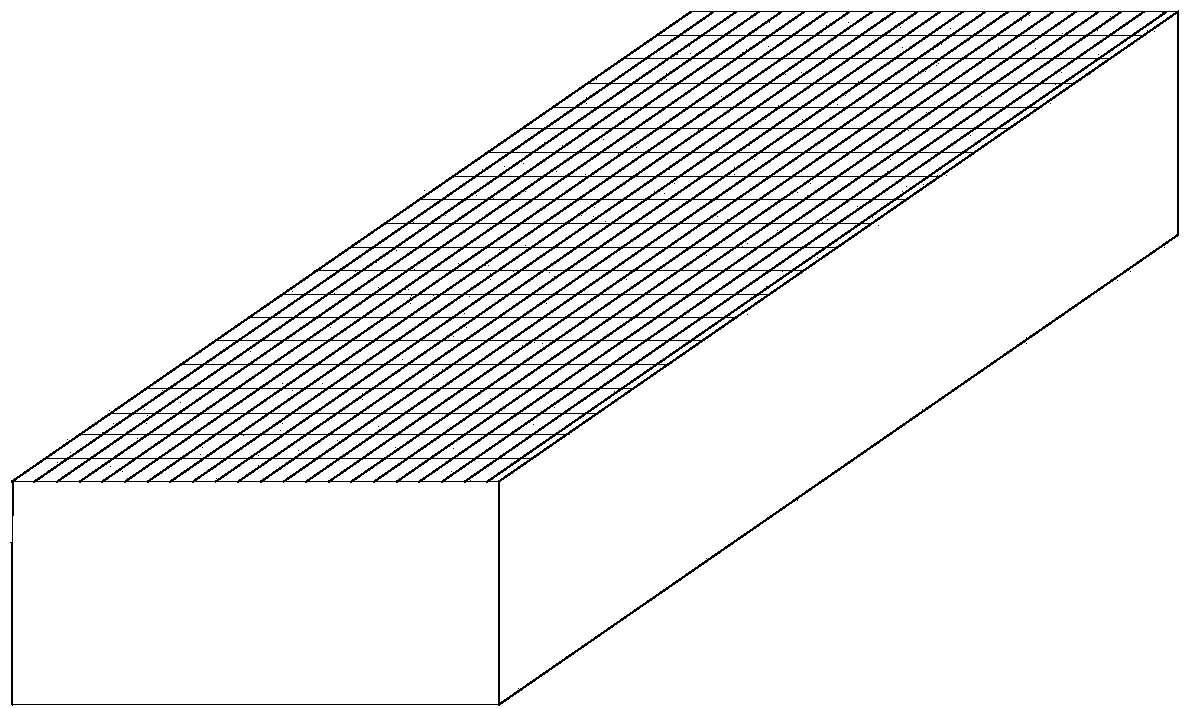

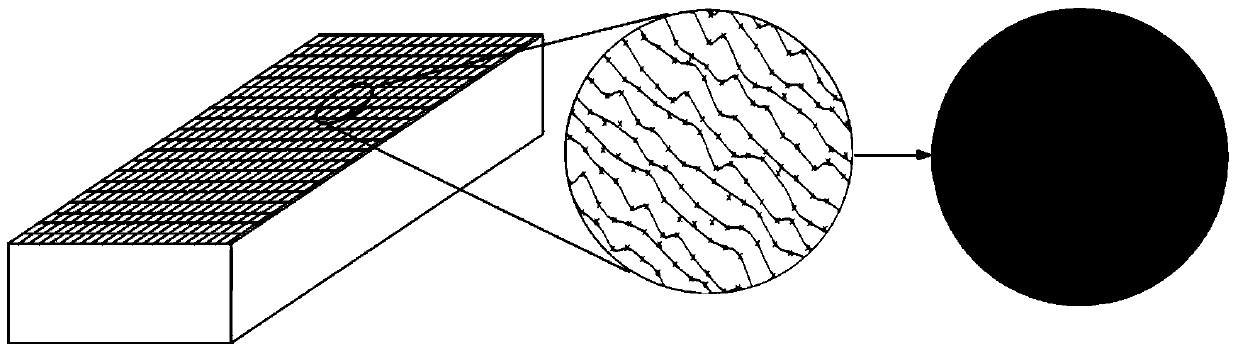

[0032] Open the part solid model of the assembly in the CAD platform, and start the VB script plug-in. Thereafter, perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com