Four-phase brushless DC (direct current) motor fault-tolerant power converter and control method thereof

A technology for power converters and brushed DC motors, applied in the field of fault-tolerant power converters and control of four-phase brushless DC motors, can solve problems such as burnout and motor overheating, prevent damage, achieve isolation and fault tolerance, and high fault tolerance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

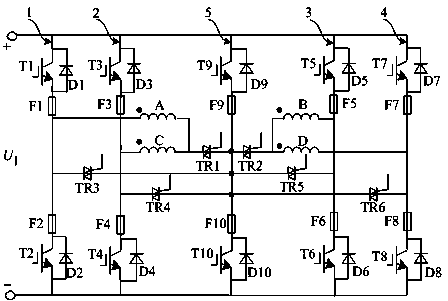

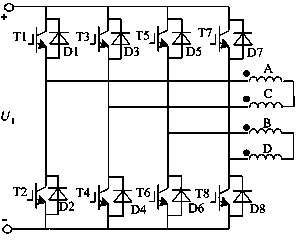

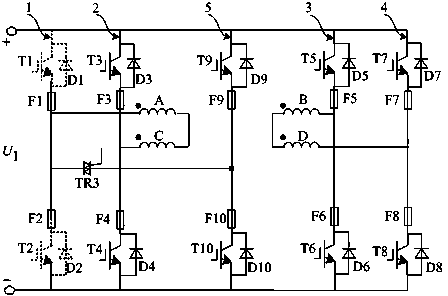

[0028] Such as figure 1 The shown four-phase brushless DC motor fault-tolerant power converter topology, the first bridge arm (1), the second bridge arm (2), the third bridge arm (3), the fourth bridge arm (5), six bidirectional Thyristors, ten fuses and four-phase armature windings connecting the arms.

[0029] The first bridge arm (1) is mainly composed of the first power tube (T1) and the second power tube (T2) in series, and the first power tube (T1) and the second power tube (T2) are also connected in series with the first fuse (F1) and the second fuse (F2);

[0030] The second bridge arm (2) is mainly composed of the third power tube (T3) and the fourth power tube (T4) in series, and the third power tube (T3) and the fourth power tube (T4) are respectively connected in series with a third fuse ( F3) and the fourth fuse (F4);

[0031] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com