Stepless speed regulation device for controlling direct-current motor for aviation industry

A DC motor, stepless speed regulation technology, applied in the direction of excitation or armature current control, can solve the problems of high power consumption of the drive itself, complex drive circuit, high blocking voltage, etc., to achieve good starting, low operating cost, smooth speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

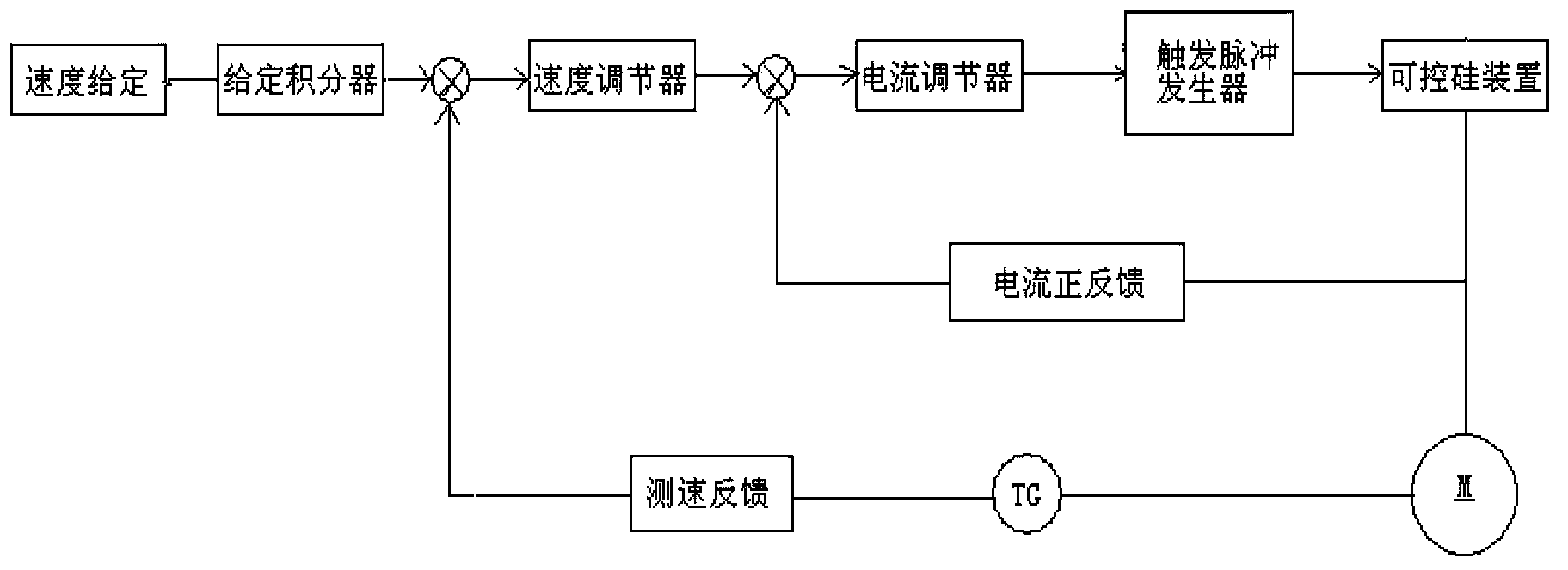

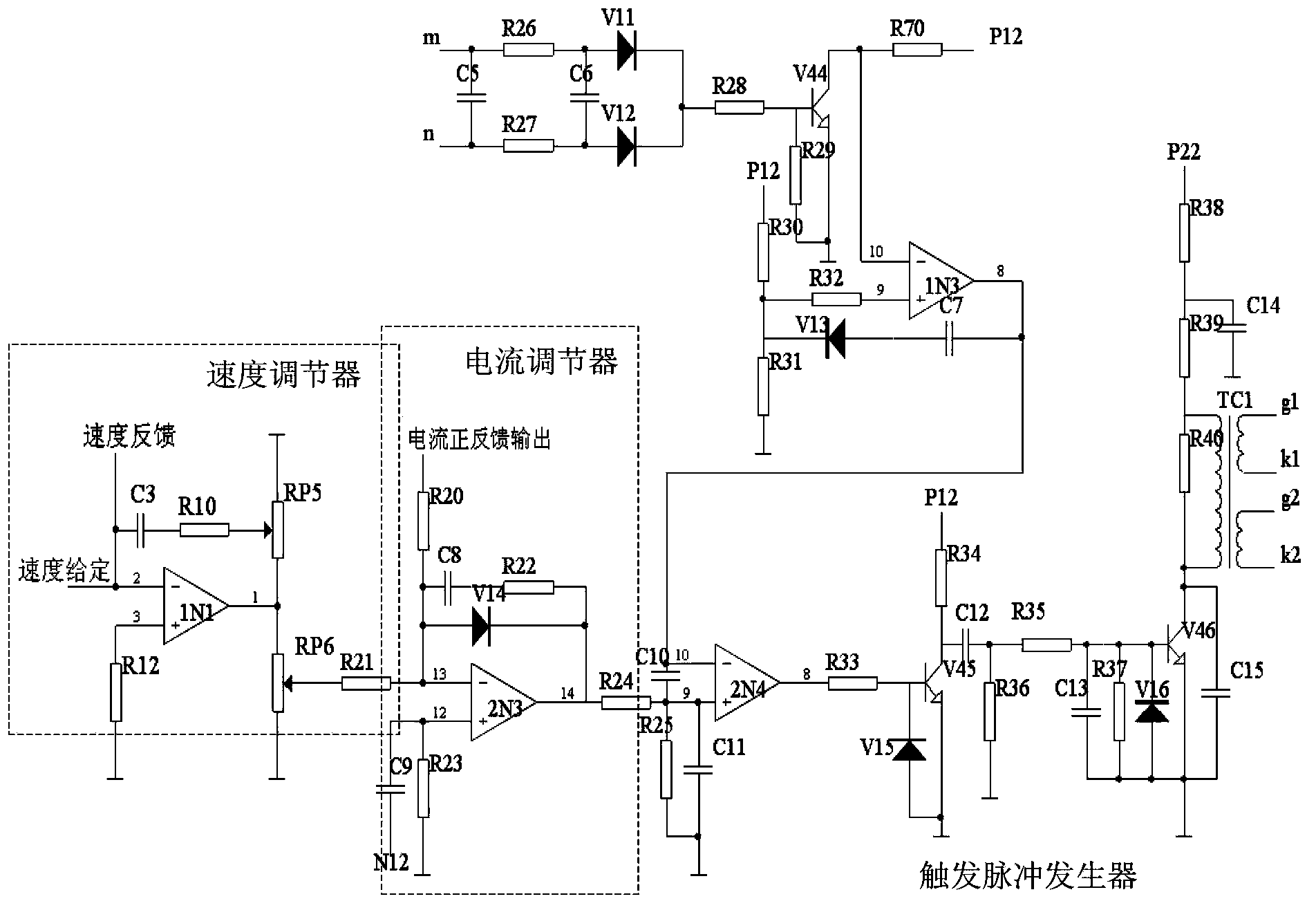

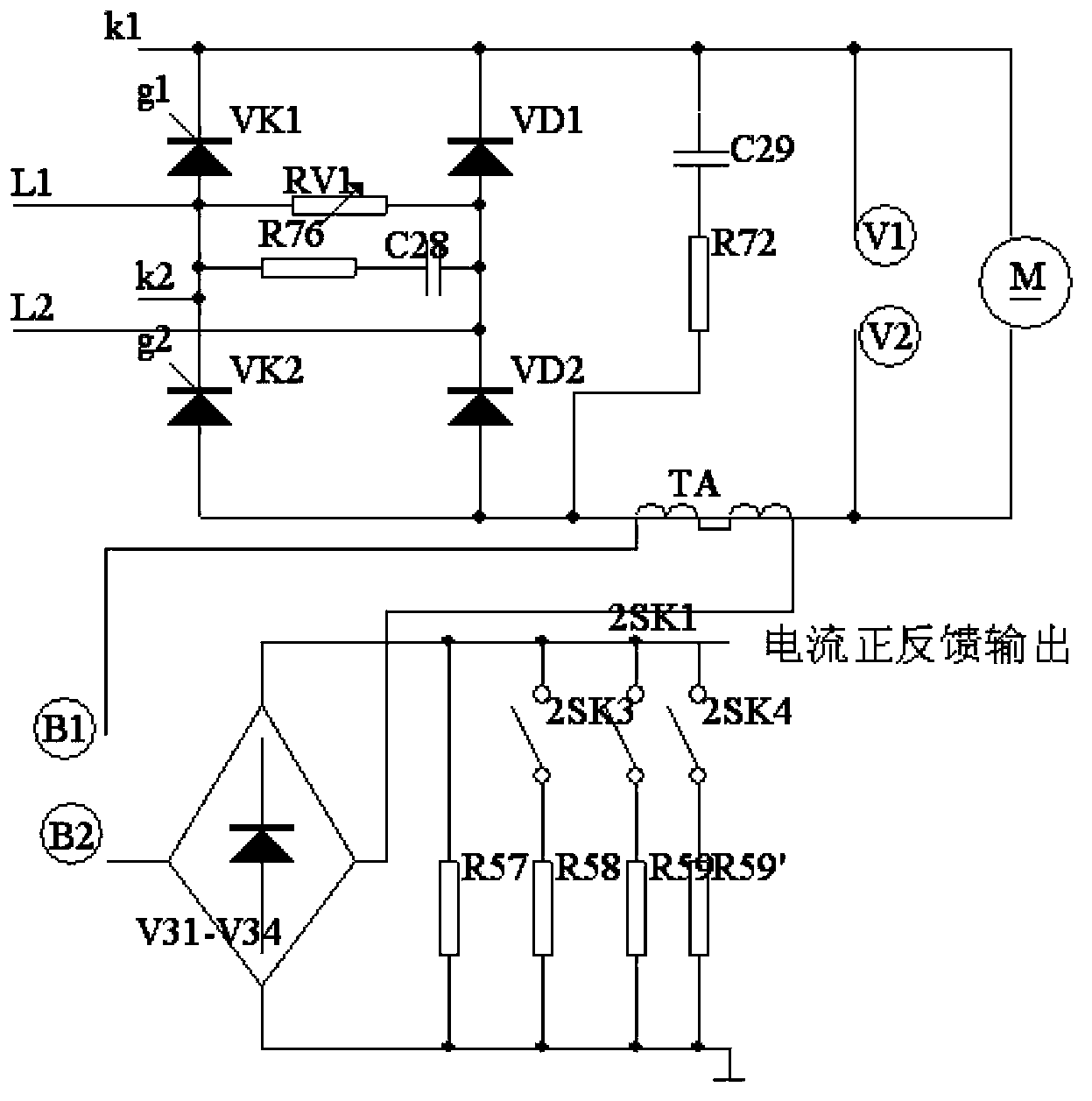

[0028] Such as figure 1 As shown, the structural design of the present invention is realized in this way: the device is a double-closed-loop speed regulation system composed of a small closed-loop current and a large closed-loop speed. The circuit of this device is composed of a given speed link, a given integrator, a speed regulator, a current regulator, a trigger pulse generator, a thyristor device and a protection circuit. Its connection is that the power supply unit provides power for other functional modules, the output of the speed regulator is sent to the current regulator, and the output of the current regulator is used to control the trigger pulse generator. After being transformed by the trigger pulse generator, it is sent to the thyristor device, so as to realize Control of the motor.

[0029] The speed given link is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com