Carbon materials for lithium ion secondary batteries, negative electrode materials for lithium ion secondary batteries, and lithium ion secondary batteries

一种二次电池、碳材料的技术,应用在二次电池、电池电极、锂蓄电池等方向,能够解决无法充分得到充放电效率等问题,达到优异充放电效率、高充放电容量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

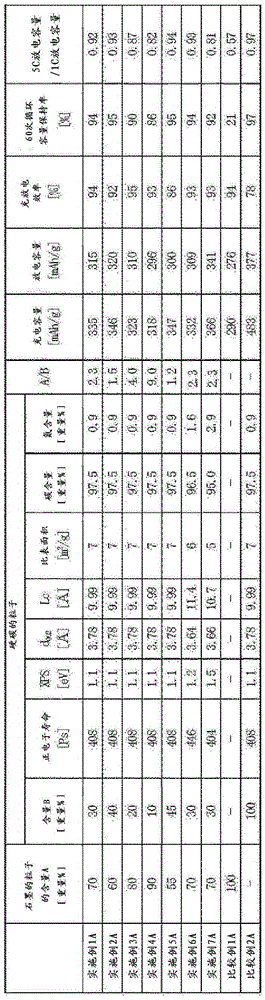

Embodiment 1A)

[0279] Phenolic resin PR-217 (manufactured by Sumitomo Bakelite Co., Ltd.) as a resin composition was processed in the order of the following steps (a) to (f) to obtain hard carbon particles.

[0280] (a) Under the conditions of reducing gas replacement, inert gas replacement, reducing gas flow, and inert gas flow, the temperature is raised from room temperature to 500°C at 100°C / hour

[0281] (b) Under the conditions of reducing gas replacement, non-reactive gas replacement, reducing gas circulation, and non-reactive gas circulation, after degreasing treatment at 500 ° C for 2 hours, cool

[0282] (c) Finely pulverize with a vibrating ball mill

[0283] (d) Under the replacement and circulation of inert gas (nitrogen), the temperature is raised from room temperature to 1200°C at 100°C / hour

[0284] (e) Carbonization treatment at 1200°C for 8 hours under the circulation of inert gas (nitrogen)

[0285] (f) Under the circulation of inert gas (nitrogen), let cool to 600°C natu...

Embodiment 2A~5A)

[0288] A carbon material was obtained in the same manner as in Example 1A above except that the contents of graphite particles and hard carbon particles were changed as shown in Table 1.

Embodiment 6A)

[0290] In Example 1A above, aniline resin (synthesized by the following method) was used instead of phenolic resin.

[0291] Put 100 parts of aniline, 697 parts of 37% formaldehyde solution, and 2 parts of oxalic acid into a three-necked flask equipped with a stirring device and a condenser, react at 100°C for 3 hours, and then dehydrate to obtain 110 parts of aniline resin. The obtained aniline resin had a weight average molecular weight of about 800.

[0292] A resin composition obtained by pulverizing and mixing 100 parts of aniline resin and 10 parts of hexamethylenetetramine obtained above was treated in the same procedure as in Example 1A above to obtain a carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com