Full-automatic seedling culture device

A seedling raising device, fully automatic technology, applied in horticulture, greenhouse cultivation, climate change adaptation, etc., to achieve the effect of improving utilization rate and raising seedling survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

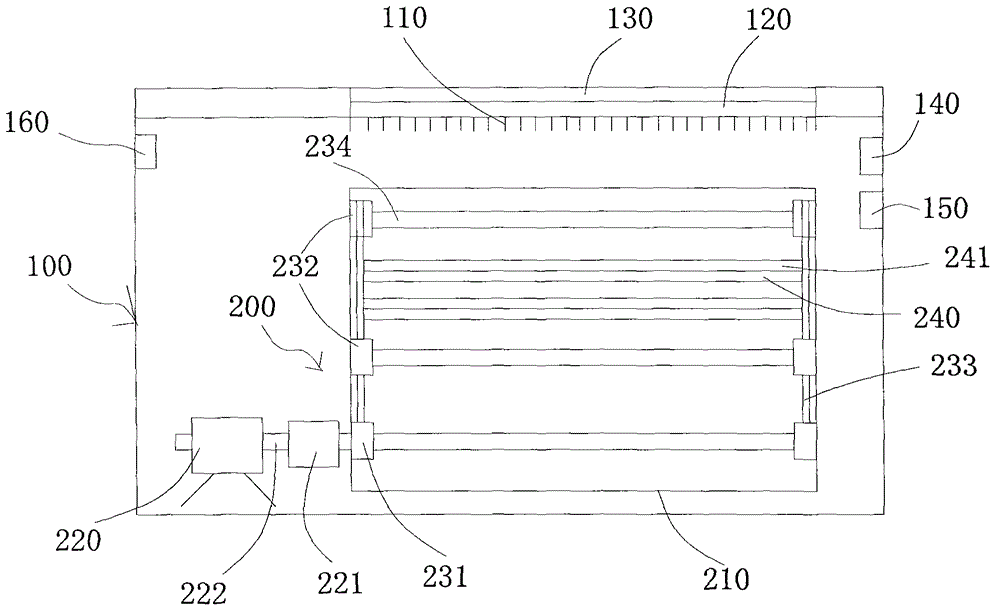

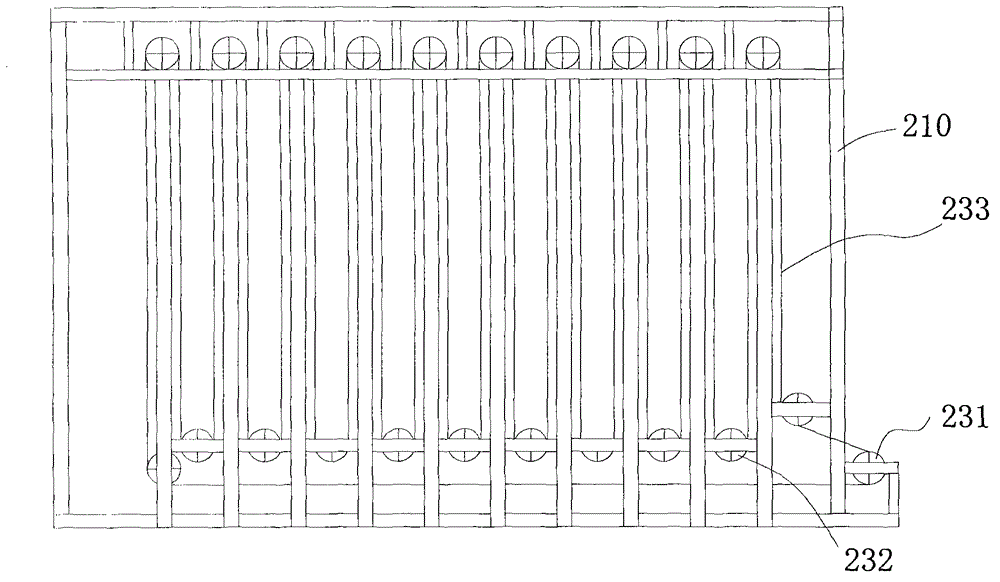

[0018] see figure 1 and figure 2 As shown, the fully automatic seedling raising device includes a seedling raising room 100 and a seedling raising tray conveying device 200. The seedling raising room 100 is a fully enclosed transparent glass seedling raising space made of heat insulating material. The top of the seedling raising room 100 is equipped with a fertilization device 130, an artificial lighting device 120 and Sprinkler 110, ventilation fan 160, temperature control device 140 and carbon dioxide monitoring device 150 are also installed on both sides of the seedling raising room 100, and a dimmer is installed on the artificial lighting device 120 to adjust the light intensity so that the light intensity is suitable for the growth of seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com