Spiral conveyor structure of sand mixer

A technology of sand mixer and sand mouth, which is applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., which can solve the problem of unfavorable working environment and workers' health, affecting the amount of resin, curing agent, etc. Affect the ultimate strength of resin sand and other issues, to achieve good practical performance, reduce maintenance rate, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

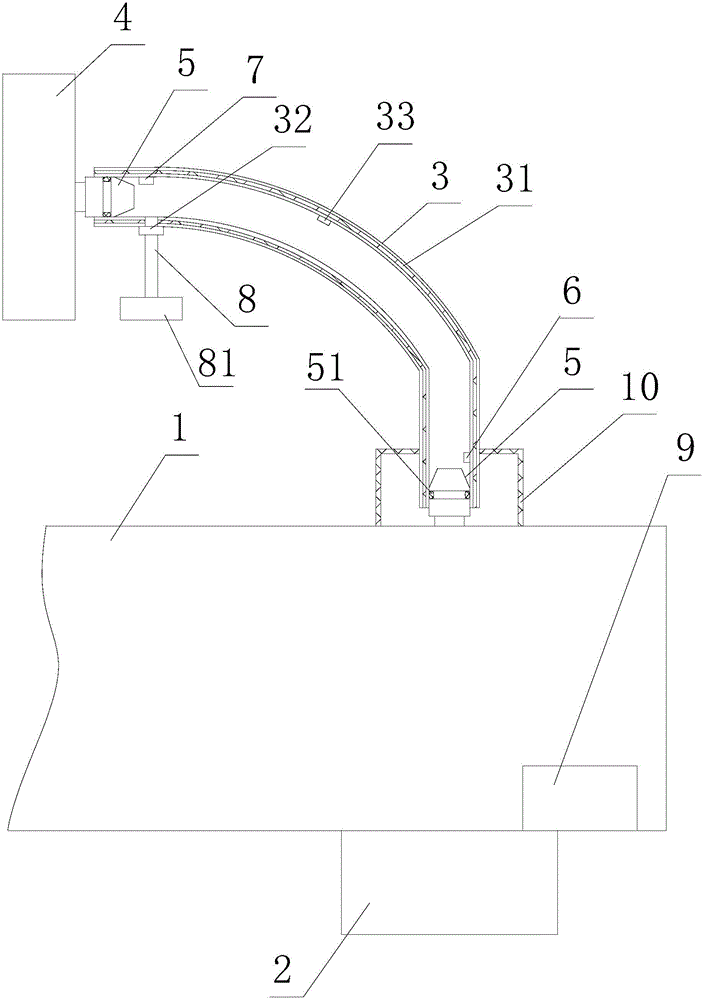

[0012] Such as figure 1 As shown: the cage structure of the sand mixer, including a body 1 with a sand outlet 2 at the end, the body is provided with a dust removal device adjacent to the sand outlet 2, and the dust removal device includes a connecting pipe connected to the body 1 at one end 3. The dust remover 4, the dust remover 4 is arranged at the other end of the connecting pipe 3, the body 1 and the dust remover 4 are provided with a connecting piece 5 for fixing the connecting pipe 3, the front of the connecting piece 5 The part is a round platform with a small outside and a big inside. The middle part of the connecting piece 5 is provided with a sealing ring 51. The rear part of the connecting piece 5 is provided with a threaded mounting part. The connecting pipe 3 is provided with a constant temperature layer 31. The feed port of the connecting pipe 3 is provided with a speed sensor 6 for detecting the air volume of the dust remover 4, and the discharge port of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com