Alloy powder for rare-earth magnet, method for producing rare-earth magnet, and powder-making device

The technology of a rare earth magnet and its manufacturing method is applied to the powder making device for manufacturing rare earth magnet alloy powder and the field of manufacturing alloy powder for rare earth magnet, which can solve the problems of low magnet, low coercive force, low heat resistance of squareness, and low production cost. rise and other problems, to achieve the effect of not reducing the coercive force, saving precious rare earths, and saving rare earths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0044] The present invention takes NdFeB series rare earth alloy magnetic powder as an example to illustrate the production process and evaluation process of rare earth magnetism.

[0045] Its production process mainly includes the following processes: raw material preparation→smelting→casting→hydrogen crushing→fine pulverization→forming in a magnetic field→sintering→heat treatment→magnetic performance evaluation→evaluation of oxygen content in the sintered body.

[0046] In raw material preparation process: prepare the Nd of purity 99.5%, industrial Fe-B and industrial pure Fe, and the weight ratio of each composition meets as shown in table 1:

[0047] The weight proportion of each composition of table 1

[0048]

[0049] According to the preparation composition of the above-mentioned 1 to 3, a total of 10Kg of raw materials were weighed and prepared respectively.

[0050] In the smelting process: the prepared raw materials are put into a crucible made of alumina, and an...

Embodiment 4-6

[0078] The difference between embodiment 4-6 and embodiment 1-3 is:

[0079] In raw material preparation process: prepare the Nd of purity 99.5%, industrial Fe-B and industrial pure Fe, and the weight ratio of each composition meets as shown in table 4:

[0080] The weight proportion of each composition of table 4

[0081]

[0082] According to the preparation composition of the above 4 to 6, a total of 10Kg of raw materials were weighed and prepared respectively.

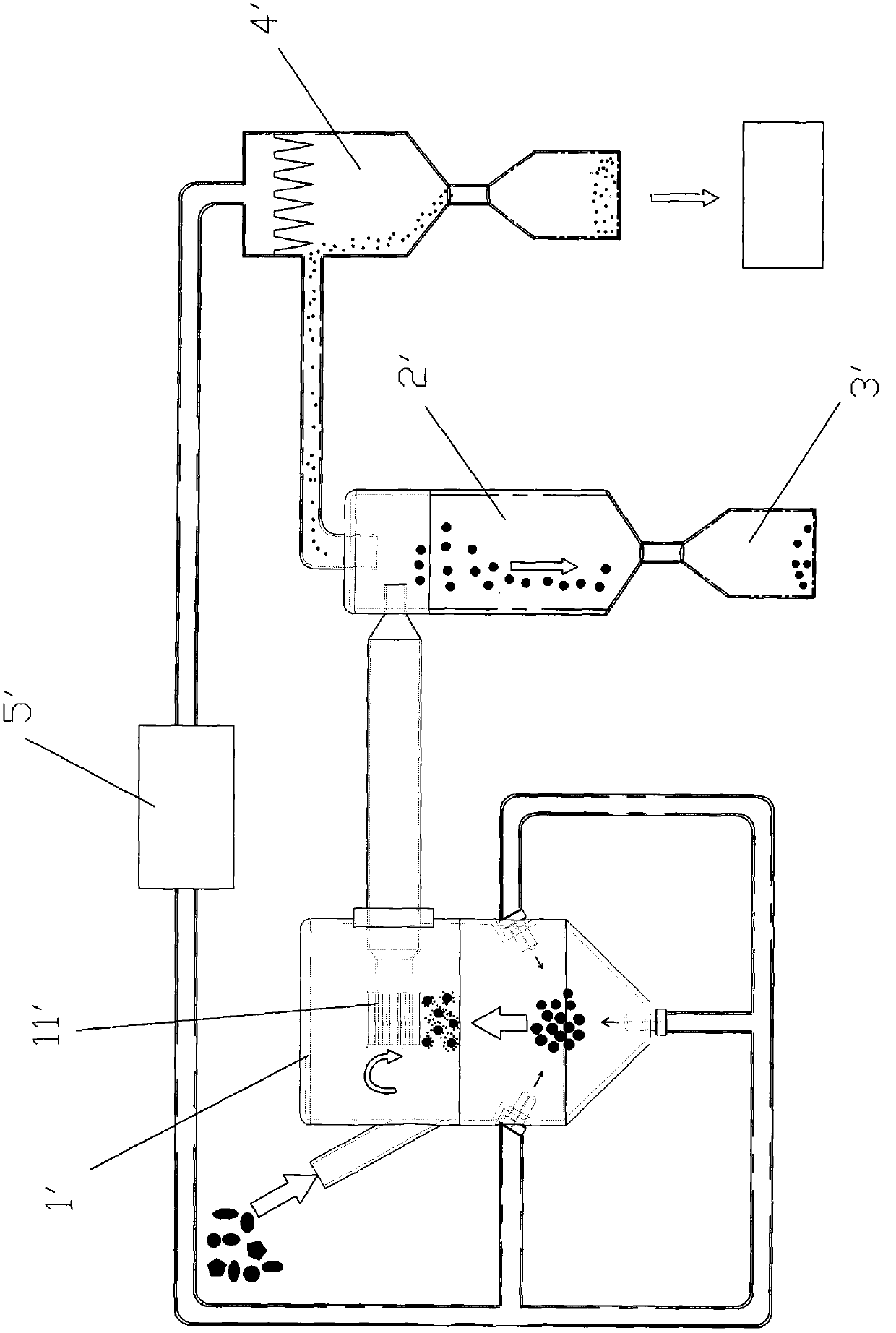

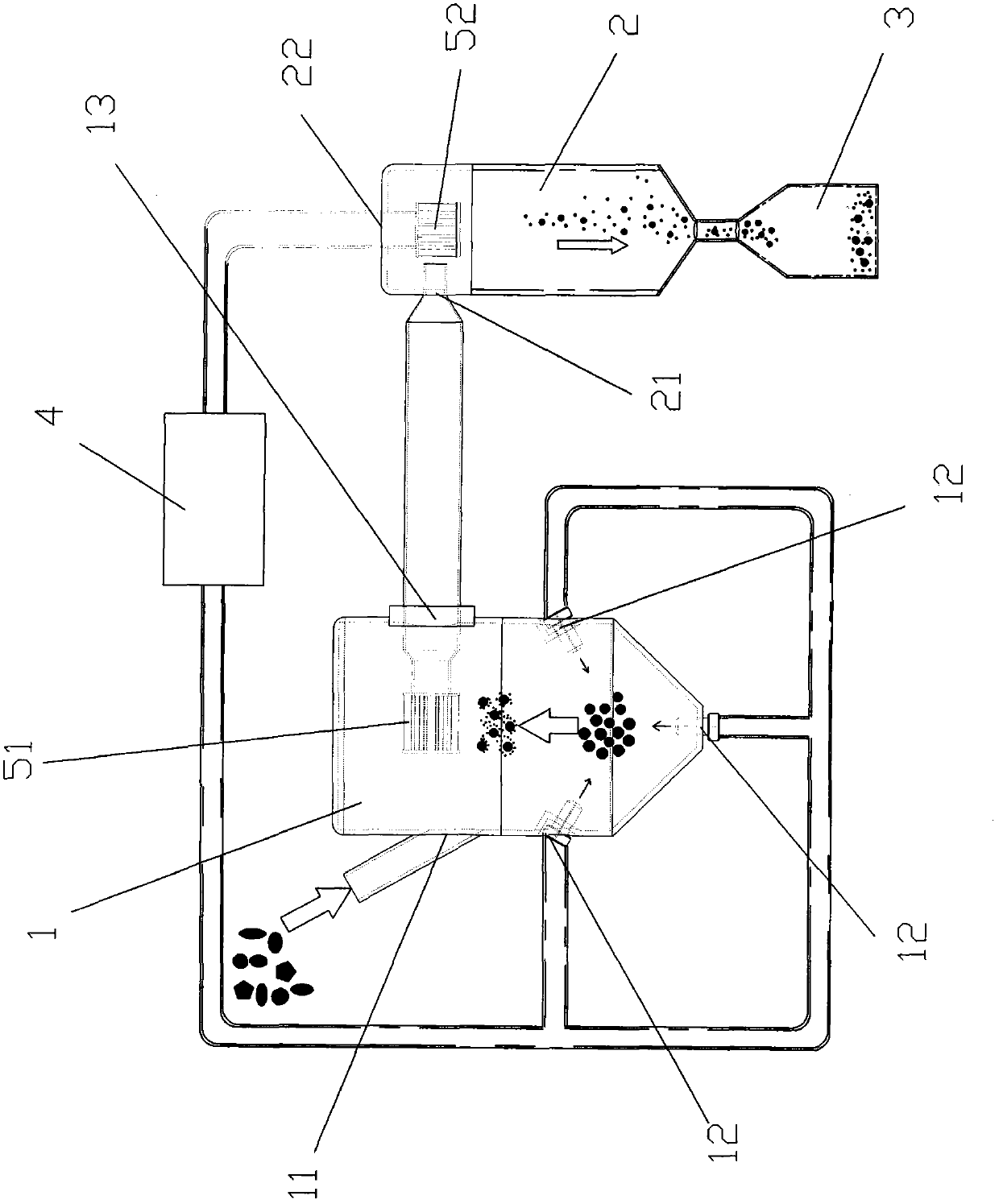

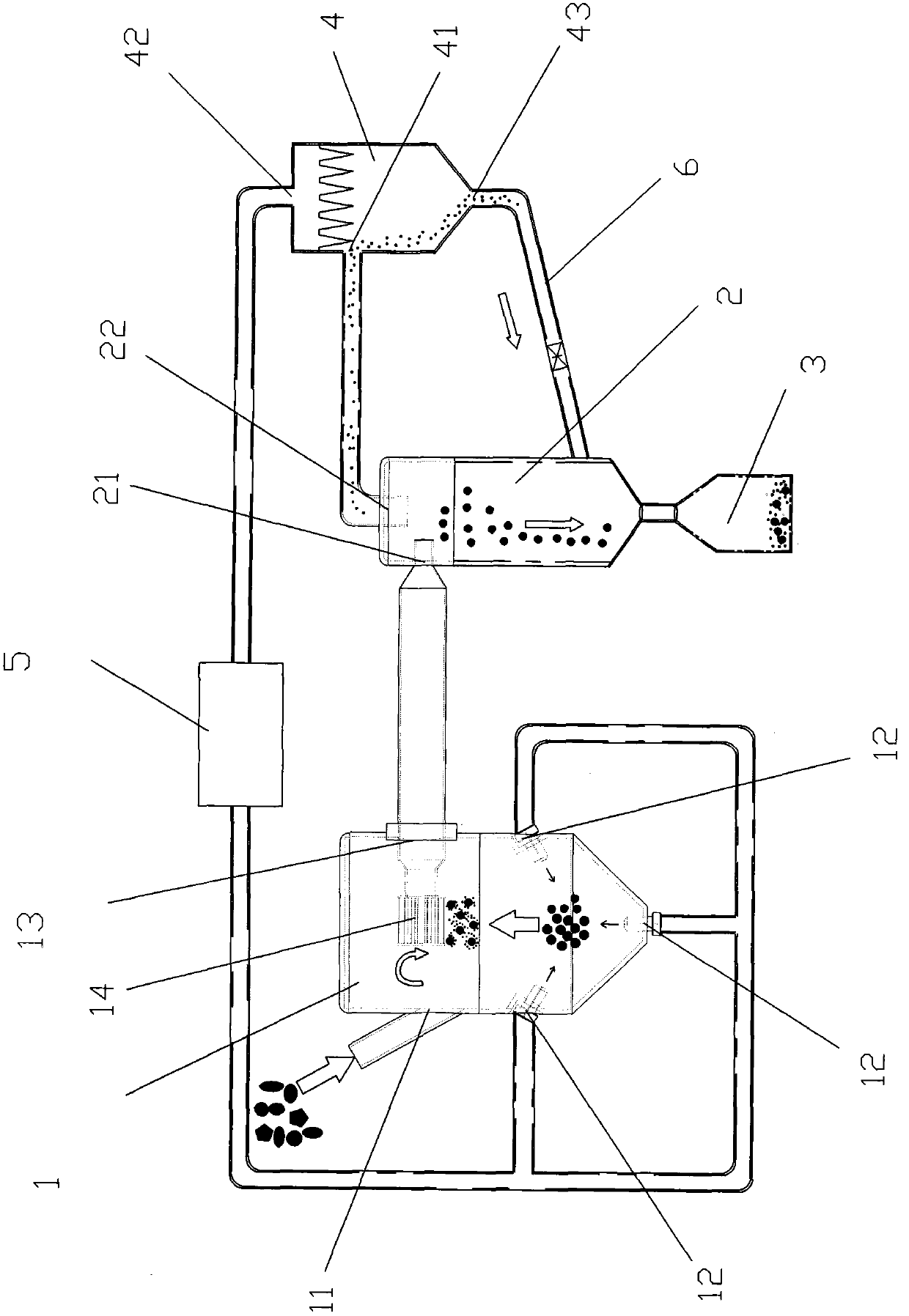

[0083] The pulverizing equipment used in the fine pulverization process is as follows: image 3 As shown in , it includes a pulverizing device 1, a first collecting device 2, a material tank 3, a second collecting device 4 and a compressor 5; The air outlet 13 of the crushing device, the air inlet 12 of the crushing device is connected to the compressor 5, and the air outlet 13 of the crushing device is provided with a filter 14 for passing the powder with a particle size below 20 μm; the first collecting devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com