High-strength composite stainless steel flagpole and welding method thereof

A welding method, stainless steel technology, applied to welding equipment, arc welding equipment, other household appliances, etc., can solve the problems of breaking, easy to cause accidents, and high cost, so as to improve the bending strength, maintain durability, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in further detail below through the description of the best embodiment with reference to the accompanying drawings.

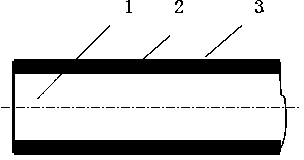

[0028] as attached figure 1 As shown, the high-strength stainless steel composite flagpole is made of high-strength stainless steel composite pipe, which is characterized in that it includes a stainless steel composite pipe body 1, a stainless steel composite pipe inner layer Q235 cold-rolled precision welded pipe 2, and a stainless steel composite pipe outer stainless steel thin-walled pipe 3 .

[0029] The high-strength stainless steel composite pipe is made of Q235 cold-rolled precision welded pipe as the base pipe and 304 stainless steel thin-walled pipe on the outside, and is manufactured by axial cold drawing of tungsten steel mold through cold drawing machine.

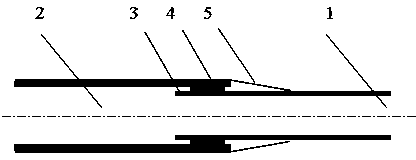

[0030] as attached figure 2 As shown, the high-strength stainless steel composite flagpole is characterized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com